Cutting-edge Technology for Modular Assembly

Flexim Open Automation Platform, developed by the young company Smart Factory, is a modular platform that makes it possible to use only one system to handle, assemble and process different products. Thanks to Beckhoff’s XTS solution, which relies on the Hepco Motion ring guide distributed in Italy by Mondial, it’s possible to overcome the limits of rotary tables, often difficult to readjust for different product versions. Flexim will be on display at the Mondial booth at SPS Italia.

di Leonardo Albino

Smart Factory, an innovative and fully Italian start-up based in Alessandria, has created a “4.0” automation system capable of providing companies with total flexibility in assembly.

“Flexim is an innovative, unique system that uses the best technology available on the market to provide an extremely flexible and easy-to-modify platform” explains Carlo Tagliabue, the company’s CTO. “The idea is simple and relies on an innovative architecture, made of a base on which the modules can be connected in a modular way, according to a given process: handling, pressing, screwing, bonding, welding, forming, printing and marking, quality control, or rather fully customized workstations, which Smart Factory is able to integrate according to customer’s specifications”.

Simplified design, reliability and precision

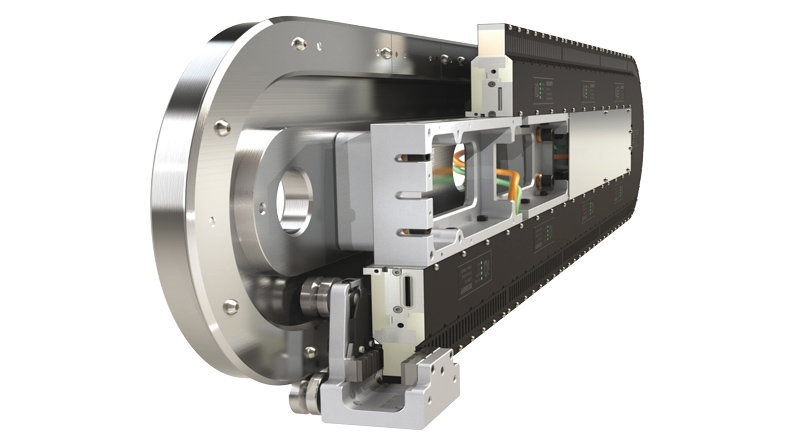

Flexim is made of a machine base, designed to manage more than 80 servo axes, which can be shared among all lines and can host any type of machining workstation. The traditional rotary table has been replaced by Beckhoff’s XTS system, a key element for achieving flexibility. The machine base is completed by modular processing stations, connected to the machine base in plug & play mode: the software automatically detects them and reprograms the processing libraries accordingly.

The XTS system is a true enabling technology to obtain flexibility and higher speed as, on a machine equipped with an indexing table, the cycle time of the slower function affects that of all the others, while – thanks to the independent carts – Flexim makes it possible to manage the queues autonomously, making the various stations independent from each other.

In addition to flexibility, some more advantages are related to simplified mechanical design, greater reliability and precision. Making a pick & place station, for example, does not require any pin or indexing.

“Each cart reaches the programmed position with very high dynamics and precisions, without any rebound or torque issues”, adds Carlo Tagliabue. The performances of the XTS system are higher than traditional independent transport systems such as the belt ones, in which pallets stockpiles, for example, often lead to annoying oscillation, slipping or skidding.

The platform is “4.0-ready”

The ring guide manufactured by Hepco Motion and distributed on the Italian market by Mondial is part of the XTS transport system. The Hepco guide system requires the use of independent carts supported by steel “V” wheels with double ball bearing. Such a guide/carts configuration makes it possible to reach linear speeds up to 4 m/s with amazing dynamics and rigidity. The Hepco guide, which makes it possible to take full advantage of the Beckhoff XTS system performances, provides an integrated lubrication system that makes the maintenance of all components subject to wear easier, resulting in an unprecedented duration. Obviously, the Flexim Open Automation System meets Industry 4.0 requirements: it is equipped with cutting-edge HMIs, with a very interactive and user-friendly design that makes the touch screen display looks like a tablet. It is also possible to access Flexim also remotely, from a multi-device perspective, thus connecting to the machine through a PC and performing any intervention on the software when necessary, or rather consulting production and performance data by accessing the cloud platform, via smartphone or tablet. The first Flexim is successfully installed at a multinational packaging company in the food & beverage sector. Smart Factory is finalizing a second machine, which will be on display at the Mondial booth at SPS Italia, in Parma from May 22nd to 24th.