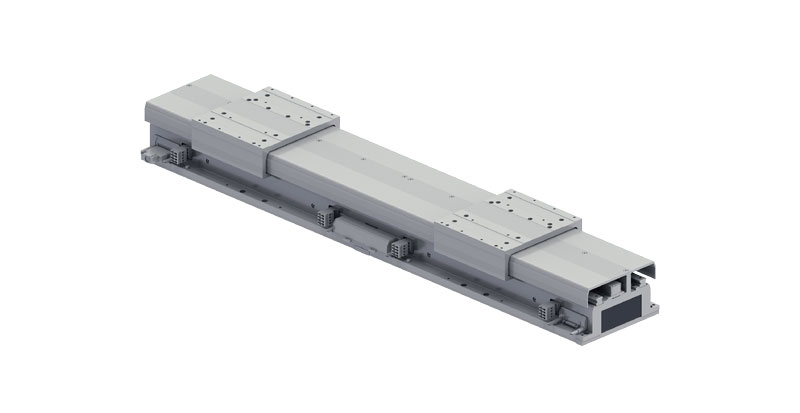

Reconfigurable linear conveyor

Yamaha launches onto market the new linear conveyor module LCMR200, undergone a major review in order to further improve ease of use, suited for work environments where intrusion of foreign matter and static noise are present.

Structured on the previous model LCM-X, this new version inherits high accuracy; moreover, rigidity has been improved through a complete reassessment of the module structure.

The linear conveyor module allows easier and more flexible line recomposition than conventional belt conveyors and roller conveyors, as well as high-speed and high-accuracy transfers. The system in which up to 64 sliders are controlled by one controller YHX is inherited from the current model LCM-X, but the newly developed Standard Profile program eliminates programming work inside the controller and makes easier builds of automated equipment.

Simplified transfer accuracy adjustments

The direct drive via its linear motor enables high-speed transfers, highly accurate stopping, and positioning. Almost the entire length of the module is installed directly on the frame to support the linear guide. The linear guide and the guide block of the slider have also been increased in size and strength, while keeping the same footprint.

The cable extraction direction can be selected from two directions, front and back, increasing the degree of freedom in electrical wiring and improving the area efficiency when constructing reciprocating lines. There is a newly developed circulation unit that greatly simplifies slider transfer accuracy adjustments. This has significantly improved the stability and durability of transit connections.