The Importance of Vision Systems in Assembly Lines

For more than twenty years Imago has been designing systems for product quality control and production line management. In recent years, vision systems have been increasingly adopted for control because they do not require contact with the product, thus maintaining high production speeds. Attilio Chillemi talked about the strengths of Imago’s software and how the company works in synergy with its customers.

by Aldo Biasotto

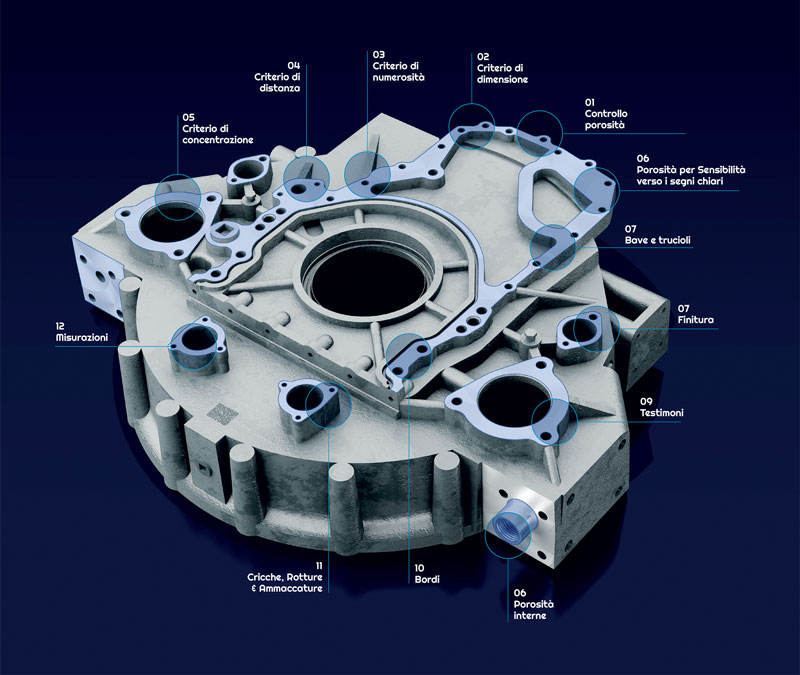

Imago is a company based in Castagneto, in the province of Brescia, which has been specializing in the design of product quality control systems and production line management for more than twenty years. Imago systems operate in line, also offering companies the opportunity to increase the technological level of their machine or line, following the most modern Industry 4.0 standards. After a first feasibility analysis, the standard Imago machines are, if necessary, customized to the specific customer needs and according to the morphology of the piece to be analyzed. Imago’s main partners are machine, plant, production and automation line manufacturers, particularly in the assembly, packaging, die-casting and wire drawing sectors.

Attilio Chillemi, Imago’s General Manager, talked about the company’s philosophy and the solutions it offers, which are always meant to be at the forefront in an ever-changing industrial environment.

How has Imago’s business changed in recent years, when vision systems have become a fundamental component of any production process?

Trust in vision systems has grown a lot, as for their effectiveness and above all their reliability. With the high production speeds now achieved, there is only one way to check the product and the cycle, and it is contactless, but it is also equally important not to cause downtime.

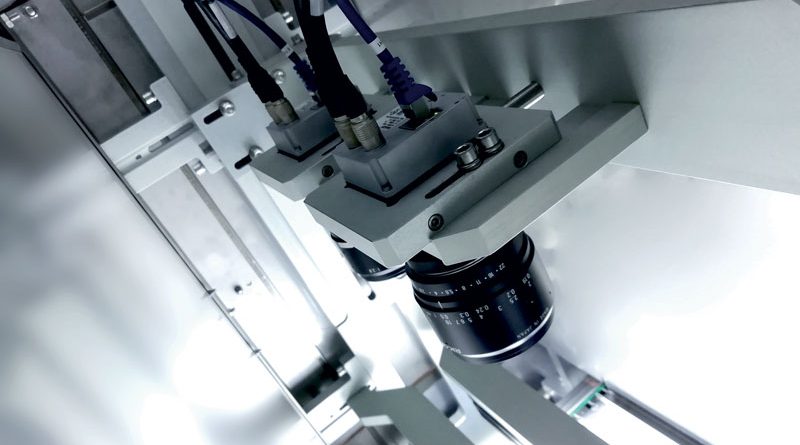

Thanks to vision algorithms, the management software developed by our engineers and the special tools used, Imago is able to create high-tech machines. They are all easy-to-use systems that makes it possible to extract a large amount of data, such as information for tracking checks on each individual piece and for monitoring the entire production process; all essential things for today’s industry.

The world of assembly has problems in some ways similar to packaging; how do you approach these sectors?

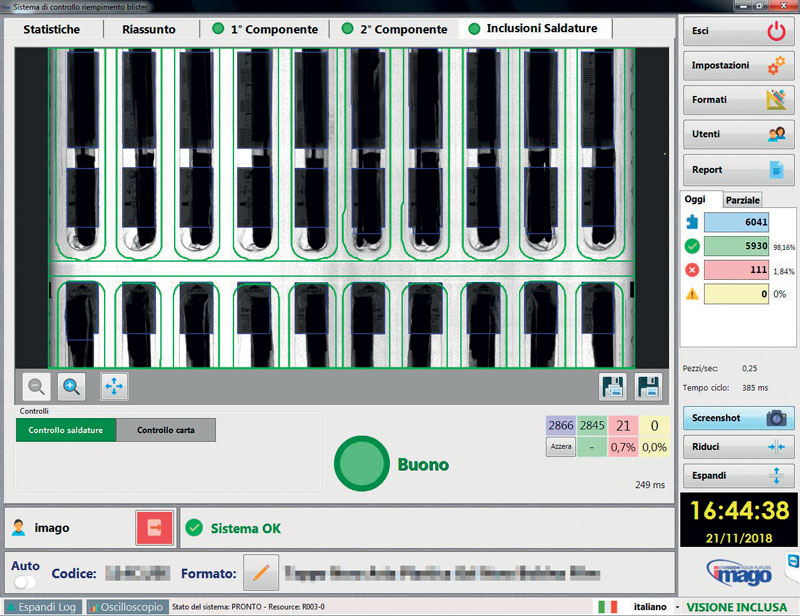

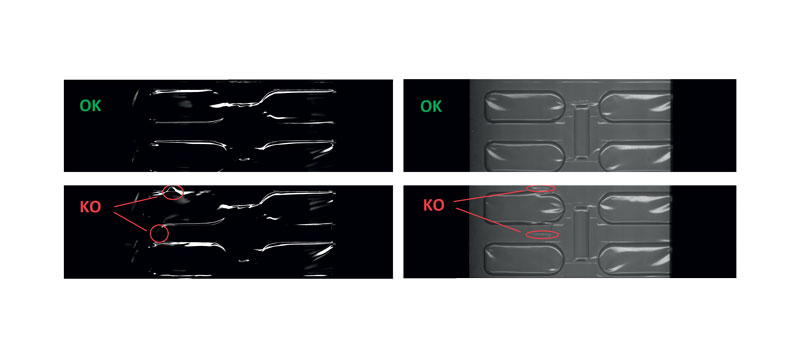

For the packaging sector, Imago has developed various vision systems for thermoforming machines, and applied in different sectors. They range from checking the presence of the packaged material to identifying extraneous matters, from checking the weld to verifying the accuracy of printing and its readability. One of our software strengths is the facilitated learning of objects and printing to be checked which allows the user to quickly and easily configure the various formats, making them autonomous in the eventual addition of new products.

This is advantageous also in the assembly sector, where sequence analysis, piece conformity and its correct assembly are the key checks, such as to ensure the quality of the final product where in some cases defects are no longer visible. In addition, the control software makes it possible to stop the machine in case of pieces or extraneous matters in the work areas.

Which are the top products in your catalog addressed to the assembly sector?

We do not have a flagship product, but systems where the main component is above all our know-how: algorithms, software as well as the right choice of optics and illuminators.

Imago is always working to find solutions to specific customer problems and to face increasingly complex challenges; doing this requires new knowledge and new approaches for examining requests. Therefore research has gained more and more importance in our work, we are constantly vigilant when new technologies appear on the market, ready to exploit their possible advantages.