Automation in green sand processing

Foundries around the world are anxious to minimize the sand-related waste in order to increase productivity and also to reduce energy costs for rework and remelting of defective castings, to protect our climate more and more.

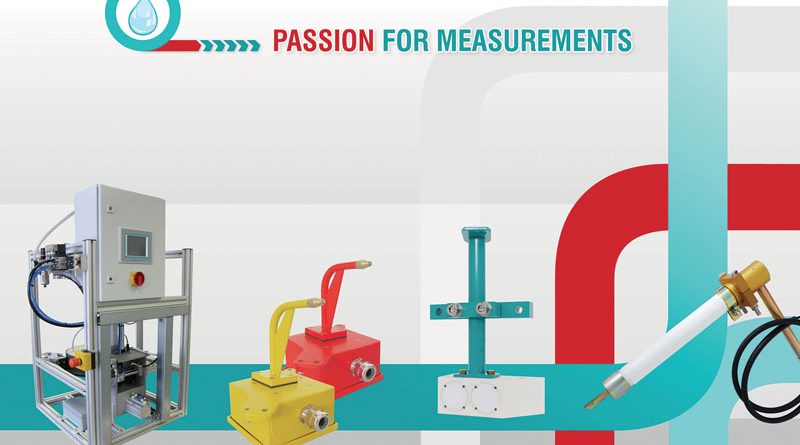

Sensor Control GMBH (Neuwied, Germany) is providing proven systems and sensors for controlled cooling and pre-moisturizing on belt conveyors, moisture control systems for coolers and continuous mixers and shake out drums, moisture control systems at batch mixers, automatic sand systems in the prepared sand in different models to capture the metrics compactibility, shear and compressive strength, moisture and temperature and as innovation the bulk density in g/cm³.

Also pneumatic additive injections and additional weighing and level sensors for monitoring of the product stream. A pouring stream inoculation system used directly in the casting process completes the program.

Gifa 2019 Hall 15 – stand H 13