Lubricoolant, Always Clean and with No Disposable Filters

The Nikuni VDF hydrocyclone (Vortex dynamic filters) removes 90% of solid particles 10 micron in size from the lubricoolant fluid of machine tools, even when machining such a light material as aluminium

by Roberto Guccione

The efficiency and accuracy of modern machine tools is also linked to a correct management of the lubricoolant fluid. The choice of the cutting fluid is important, but so are the cleanliness of the liquid and the absence of suspended solid particles. Aeration&Mixing, an English company, responds to this demand with its VDF (Vortex dynamic filters) filtration systems, developed by the Japanese Nikuni group, specialized in the production of industrial pumps for special applications and water treatment and filtering plants. In October, in Milan, during the 31st BIMU trade show, the English company presented the renewed range of Nikuni hydrocyclones, filtration systems which can remove 90% of solid particles larger than 10 microns from lubricoolants without using filtering media which need to be cleaned from time to time or disposed of in landfills. “The new Nikuni VDF CL-1000 premiered at BIMU”, Peter W. Pridham, Managing Director of Aeration&Mixing, the European distributor of Nikuni cyclone filters, explained. “Now the VDF range includes hydrocyclones which can process from 20 to 1,000 litres per minute in closed circuit. The system’s flexibility allows a wide range of configurations, ranging from manual and mobile stand-alone solutions to automatic systems mounted on board the machines, right up to centralized plants for the treatment of the lubricoolant”.

The advantages of the physical separation of solid impurities

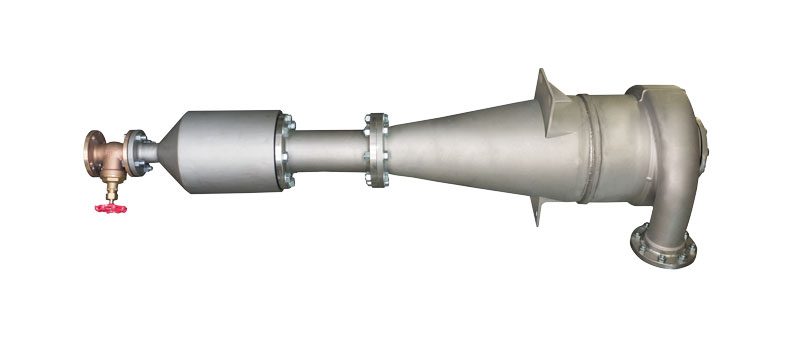

Nikuni hydrocyclones derive from complex fluid dynamics studies which allowed to identify the optimal cone-cylinder shape of the separating element, but their functioning is extremely simple. The fluid which needs to be treated is driven under pressure into the top part of the filter’s body, where a high-speed vortex flow is generated. Due to the centrifugal force, solid particles are pushed to the lower part of the filter and settle down in the collection element, while the purified liquid flows immediately towards the top exit channel and is recirculated. When the collection element is full, a valve which can be operated manually or automatically expels the collected sludge along with a small amount of fluid.

Separation of solid particles therefore occurs without filtering media, moving mechanical parts or pipes which could clog, providing cleanliness levels for the lubricoolant which would be hard to achieve with conventional systems. The only operating limit is given by the specific weight of the corpuscles which are meant to be separated, which in a water-based lubricoolant must be higher than 2. The hydrocyclone may therefore be used wih almost all materials machined using machine tools or grinders, from metals to graphite right up to stone and marble. Even in the case of a light metal such as aluminium (specific weight 2.5), the Nikuni hydrocyclone separates at every passage 65% of particles 3 micron in size and 95% of 10 micron particles. The material extracted is a uniform sludge which may be recycled along with other machining scraps, thereby eliminating machine downtimes, costs and environmental impact of disposal in landfills of the contaminated filtering media used in traditional systems. Other advantages are the very low maintenance requirements of the hydrocyclone and the consistency over time of the fluid’s cleanliness level, which is not affected by progressive decay and clogging of mechanical filters which occurs with traditional systems.