O.M.LER Starts the Production of the New Decoring Machine DCB18

The innovative decoring machine is the only one equipment that can remove simultaneously the sand core from 4 castings with a weight of 70 kg each. It is the most efficient and customisable decoring solution for high-volumes foundries

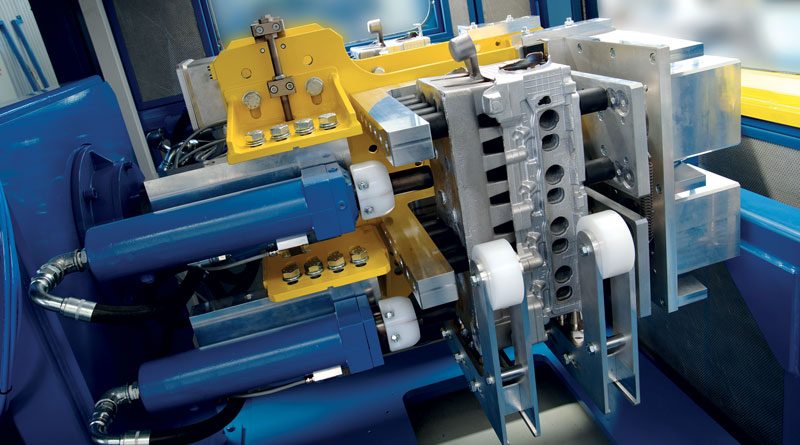

O.M.LER srl is globally well known both for its pneumatic decoring solutions RVC70 and AF1470 and for customized solutions like the decoring benches which are manufactured according to every customer specific needs. Now the company is ready to launch on the national and international market the innovative decoring machine DCB18, the first ever manufactured equipment in the world that can process simultaneously up to 4 ferrous or non ferrous foundry castings. The decoring machine DCB18 is entirely produced at O.M.LER’s facility in Northern Italy and it is the result of an intense Research&Development activity that involved the company technical staff also during the Covid-19 emergency situation. The DCB18 decoring machine, for which a patent is pending, holds in itself the many years O.M.LER’s know-how about performances, efficiency and automation, offering innovative technical solutions. The new decoring machine enables the simultaneous removal of sand cores from various cast iron, aluminium and steel castings produced through the low pressure or gravity foundry methods. Each casting can weigh up to 70 kg, including sand. Each decoring machine DCB18 can process from 2 up to 4 castings at the same time using at least a couple of pneumatic decoring hammers for every casting. The housings where the castings are clamped can be designed and manufactured according to the casting dimensions. A particular and unique feature of O.M.LER’s deco-

ring machine DCB18 is that it allows a rotation movement up to 360 degrees in both rotation directions, without breaking the pneumatic decoring hammers work. Obviously, all O.M.LER’s decoring hammer models can be fastened to the machine structure. For safety reasons, the DCB18 decoring machine is mounted into a certified soundproof cabin in accordance with the European regulations EN 1090-1:2009+A1:2011 and UNI EN ISO 11690-1.

Inside the soundproof cabin a hopper to collect the sand removed from the castings or a conveyor belt to bring it outside the cabin can be placed.

Loading and unloading of the castings can be manual or automatic using a robot outside the soundproof cabin. Thanks to its structure, the DCB18 decoring machine is the right equipment to process large batches of castings.