Silca Italia, a Fresh Start After Covid-19

Specialized in providing customized thermal insulation solutions for non-ferrous foundries, the company has continued production even during the health emergency and now looks to the recovery by focusing on innovative materials and international markets

We meet the two partners Stefano Zamuner and Maurizio Golfetto at the headquarters of Silca Italia in Scorzè (Venice). Silca produces materials for thermal insulation, in particular for the non-ferrous foundry sector and for the thermo-acoustic sector. In the latter case, fibreglass textile products for fume extraction systems, custom-made gaskets and in particular a vermiculite-based product called Calorite, used especially for domestic stoves, fireplaces and heating.

When was the company established?

The company was founded in 1982 and then sold in 2000 to a company based in Milan; the pressure of the crisis between 2008 and 2009 led to changes, however the plant in Scorzè has always been in business with positive results. This convinced us in 2012 to talk to the top management of Calsitherm, a German supplier of ours interested in maintaining and increasing their presence in the Italian market, who acquired 60% of Silca’s shares, a situation which is still the case today.

Italy is the second largest aluminium market in Europe, what are your typical customers and markets in this sector?

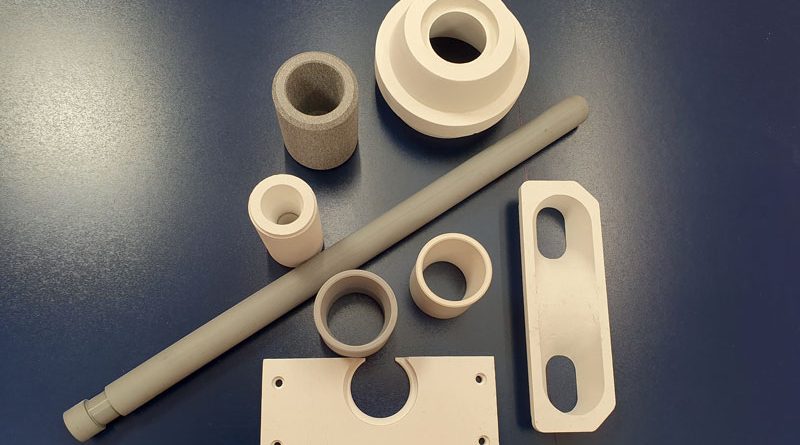

Silca Italia is a production unit with eleven employees and a turnover of more than two million euros per year. We are specialized in the supply of all the parts which allow the passage of the liquid metal from the channel furnace to the ladles, up to the mould. In the aluminium sector, we operate mainly with low pressure foundries, where Italy excels in competence and quality. We are also suppliers of other aluminium foundries, from remelting for extrusion billets to ingot manufacturers, and cast foundries in general. Our customers are specialized in very different sectors, from automotive (engine blocks, suspensions, rims) to engineering, meant as design and production of thermal insulation in different fields of application, such as glassware and production of parts for household appliances. Silca’s strength has always been its focus on market diversification; in other words, automotive is not our main market, even though it is the largest outlet sector for Italian foundries. A sector which, as a result of the Covid-19 emergency, practically came to a halt, but diversification rewarded us and allowed us to overcome the terrible pandemic crisis of recent months with less difficulty than others. We still hope that the car sector will start again as soon as possible, because it is an area of excellence in which our country holds a very important position for all European car manufacturers. Just to mention one example of Italian excellence, all BMW 4-cylinder cars are fitted with an engine block produced in Modena, where about 360,000 units are produced each year.

And what about exports?

Our parent company Calsitherm produces the basic material which is distributed and marketed by various commercial and production units and has founded several Silcas in various countries. So there is Silca Germany, our Silca Italy, Mexico, South Africa, Malaysia and in the last two years one company in the Netherlands and one in England.

How did you spend the recent lockdown caused by the Covid-19 emergency?

Having many customers in sectors considered strategic, such as plastic moulding machines, which were allowed to continue according to Ateco codes, we have practically always been operational and fortunately we also managed to avoid the use of the redundancy fund. Of course, we were unable to maintain last year’s turnover, but at any rate, sales and activity did not stop. Now we see the first signs of a new start in the automotive sector as well.

What is your strength today, in a competitive market with very strong competition even from Chinese manufacturers?

Today by simply clicking on the Internet, you can find everything. What is missing is a product processed, assembled and composed of various materials allowing customers to improve the performance of their production and ensure cost and energy savings. In practice we work on a project “ tailoring” ad hoc solutions for the customer who does not require simple and standardized solutions. We work following a design. For us pure trading is not an interesting part of our turnover. We aim to transform our product into customized solutions. We have objective strengths: for example, our calcium silicate produced by Calsitherm under the trade name Calcast®. Available in various formulations, it has a higher density than competing materials and improves mechanical properties while reducing wear and tear. The flagship product is the innovative Calcast CC155 G4-G8-G16, a calcium silicate containing different percentages of graphite (Calsitherm’s exclusive worldwide patent), which allows components to be manufactured without retaining aluminium residues after melting.