State of the Art and Innovation of the Pressure Diecasting Industry in the Italian System

Italy is the second European producer of die castings meant for the most sophisticated industrial segments

by Anthony Tropeano, Senior Advisor Foundry Ecocer, Maurizio Sala, CEO Foundry Ecocer, Nazario Ghislandi, S.V.P. Foundry Ecocer

The aluminium pressure die casting industry has been one of the most innovative sectors in the field of non-ferrous metallurgy in Italy for many years.

In our presentation we shall describe along general lines this important segment of foundry casting in Italy, underlining the relationships with the downstream industrial sectors which this type of foundry castings are meant for, therefore particularly the automotive market and connected sectors. A general picture is shown in figure 1, where the final destination of aluminium die castings is shown. Aluminium has an increasing importance in recently produced European cars, ranging from 62 kg per vehicle for a Smart Fortwo to 610 kg for a Range Rover Sport. A significant scheme of the growth in the use of aluminium in cars up to 2020, subdivided by type of semi, is represented in figure 2. Having defined the importance of the transportation segment for light alloy castings, the diagram in figure 3 shows the trend of the European production of molten aluminium castings from 2000 to 2017, the year when, after the crisis around 2009, the output went back to the 3.5 million ton level. The trend of quantities of aluminium castings manufactured in 2000 in the EU28 countries is shown in figure 4; the data show that around 75% of castings produced come from 4 countries, starting from Germany, leading with about one third of the total, followed by Italy and, at a considerable distance, Poland and France.

The Italian HPDC system

The strong interest of Italy for the aluminium alloys pressure die casting sector is well highlighted by the 6 world level domestic companies that design, build and install pressure die-casting machines; around and behind this important upstream segment, we must remind the huge market consisting of hundred companies that produce and supply the necessary materials and components: special steel foundries for all the mechanical components; designers and producers of the die-casting moulds; punching plugs and related moulds; suppliers of mechanical, pneumatic and electronic systems; industrial automation with robotics installed and engineered in the automatic casting; manipulators, automated pre-machining lines, sprueing and deburring; furnaces; producers of metallurgical treatment products and consumables.

The current scenario is dominated by the increasing demand from car manufacturers, and from the entire freight transport sector, of bigger foundry casting aluminium pieces with a better combination of mechanical properties, low weight, reduced wall thickness, absolute microstructural integrity. An increasing interest for industrial uses of new aluminium alloys for pressure die-casting, heat treatable and weldable, is being recorded, stemming from the cooperation between end users, die casting foundries, metallurgical laboratories of many Italian universities such as the Turin and Milan Polytechnics, the Universities of Brescia, Padua and Vicenza, Ferrara and prestigious metallurgical Research and Control Centres such as AQM-CSMT in Brescia which for the past years has inserted into its training programs the High and Low Pressure Die Casting School. Actually, from a metallurgical standpoint, the great innovation in the industry lies in the new properties of raw material for aluminium die casting, decades ago the phrase used was secondary alloys and the term referred both to the origin (remelted metal) and to the quality (second class), nowadays with new smelting and casting techniques and greater care in production (more attention to the metallurgical cleaning treatments in the furnaces, the development and installation of in-line degassing plants, the widespread industrial use of filtration and cleaning systems for aluminium alloys in the casting phase, and of sophisticated quality control instruments of porosity and cleaning index, complete data recording etc.).

Remelting may compete in many case with smelting as regards the metal’s cleanliness properties, and therefore the integrity guarantee of the final castings. Besides the continuous improvement which has been going on for years regarding the metallurgy of die casting aluminium alloys and the process technologies, another area of important evolution concerns the sector of machines and equipment, with a significant increase in the power of die-casting machines. Demand is currently focusing on presses of power up to 5.000 – 5.500 tons, real giants when compared to the maximum powers normally available until a few years ago.

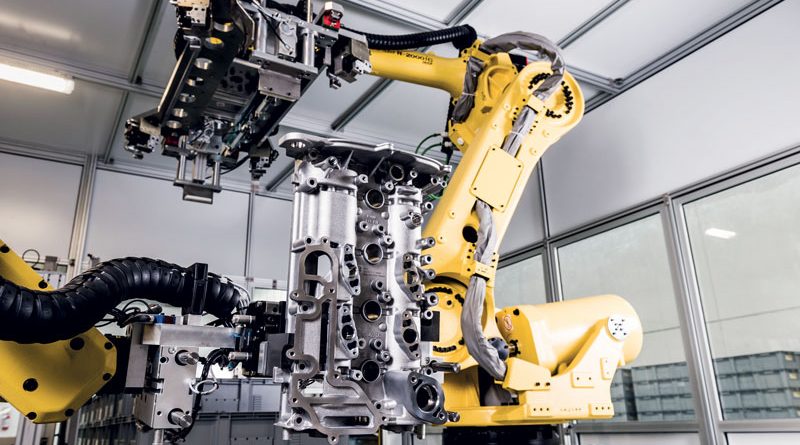

This virtuous process of innovation in the domain of aluminium die casting in Italy is concluded by the continuous increase in automation and in the use of robots in die casting, a positive trend that increasingly qualifies the role of the operator, who now has further instruments in order to be the complete manager in charge of the process.

Our company, FOUNDRY ECOCER, participates as one of the top players in this great technical scenario involving an important Italian manufacturing sector such as foundry casting and aluminium die casting, and for years it has supported the great exhibition event, Metef, largely dedicated to promoting the knowledge and visibility of the segment where Italian industry and technology are in a leading global position.