Takler strengthens production and targets the global market

Takler has invested in its Matera plant by setting up a new 2,800-ton extrusion line. The company now produces in-house all the light alloy profiles used in the manufacture of accessories and components for industrial vehicles. Lorenzo Lorusso, CEO of Takler, described the opportunities opened up by this integration upstream of the production process.

The Basilicata region, specifically, the Jesce industrial estate near Matera, hosts the Takler Srl plant, which produces, distributes and sells steel and aluminium components for the road transport sector. Founded in 2005 by the Lorusso family, Takler is part of a well-established business group which has been operating in the automotive sector since 1989. In 2008, Takler opened its own subsidiary in Germany to offer an efficient logistics service in northern Europe, and in 2017 it went beyond the European borders with a subsidiary in the United States. In a short time, Takler has become a benchmark for the commercial vehicle sector. Today, the company has a portfolio of more than 2000 customers worldwide thanks to its solid know-how, its close attention to market developments and its search for original, decisive and reliable solutions. This context is reflected in the strategic decision made in 2019 to consolidate the company’s structure and production mix with the installation of a brand new 2800 ton extrusion press, with the aim of producing the aluminium profiles used in the products in-house. It is well known that the need to lighten means of transport in an attempt to reduce consumption has made aluminium a very useful metal in the production of both structural elements and accessories. Aluminium and its alloys are the future of the transport industry and already today more than a third of all the light metal used in Europe, about 14 million tons, is used for mobility. We spoke today about this new extrusion plant and the prospects opened up by this investment with Lorenzo Lorusso, Managing Director of Takler.

Takler is a young and very dynamic company whose origins lie in the marketing of vehicle accessories. How are you structured today?

Our company was founded to establish itself in the production and distribution of components for the automotive industry and in particular for the “Truck and Trailer” sector. We have shared out the tasks within our family. The eldest son Domenico Lorusso runs the plastics division as CEO of Lokhen, another company in the group. The second-born son Giovanni is in charge of the American subsidiary Takler USA as CEO and the third-born son Giuseppe works for Takler as General Manager. Our experience garnered over the years in this industry, combined with our willingness to always seek out new solutions and new products, has convinced us to develop an increasingly complete role as a strategic partner within the market where we operate. We have therefore thoroughly evaluated the interesting opportunities offered by extrusion, due to the variety of shapes and characteristics it can provide. We did not settle for what was available on the market. We are aware of the skills we have acquired and we want to offer original solutions to our customers or create new ones in partnership with them; these are the reasons why we too have decided to invest in the aluminium sector in 2019.

Let us start talking about numbers, could you provide some details regarding your turnover, how the pandemic affected you and some data on your new plant?

From a turnover of 14 million euro in 2020, this year we shall exceed 32 million euro in turnover, an increase of around 130%. For 2022 we have budgeted for further growth, which should take us up to 50 million euro, also through the introduction of new products on the market. As regards the crisis linked to the pandemic, I can say that in reality it has only slowed down the implementation of our projects, marginally affecting a growth phase which, in any case, is positive, well planned and already under way. Regarding the structure, our production unit covers a total area of 30,000 square metres, 14,000 of which are indoors; we have about 90 employees, including design, production and sales; to complete our production we can rely on five-axis work centres to machine the various components. Finally, regarding the new extrusion line, the theoretical production capacity of the press can exceed 15,000 tons when working on full shifts and at full capacity, and this year we shall exceed 10,000 tons. Allow me to express a concept which is at the basis of our investment: we have decided to acquire an aluminium extrusion plant with related work centres to serve customers in the automotive sector, our reference business. Our aim is to be able to produce many of the products we supply to our customers in-house, from raw material to finished product, a characteristic which makes us unique in the market. There are no other manufacturers of accessories for industrial and commercial vehicles who also have an in-house aluminium extrusion plant. We have decided to invest because we believe that by doing so we can expand our catalogue, offering new products but also monitoring the production process better, with a much more positive result both for us and for our customers in terms of quality, reliability and price.

What products do you manufacture today, do you have an extensive catalogue?

We already have in our catalogue several hundreds of items designed and manufactured by us, such as “ biker guard “ side protection kits, aluminium doors, series of tail lifts, ladders (available also in steel), bumpers, side panel strut systems and more. In particular, the range of rear doors is called ‘Knock’, while the aluminium struts are part of the ‘Klever’ series. The rear doors are actually a very important element for us and for our customers. It is clear that the key to success and the best penetration in the domestic and international market is in the design and implementation of winning solutions, an exclusive work which is the result of the technical knowledge, commitment and experience of the team of engineers working with us. Today, a couple of years after the installation of the extrusion press, we already have a wide range of original and innovative solutions, which are able to enhance the exceptional shape, strength, toughness and aesthetical qualities of aluminium extrusions. We are practically close to covering all the production and processing availabilities of our plants.

Let us now talk in more detail about the extrusion press and the downstream equipment.

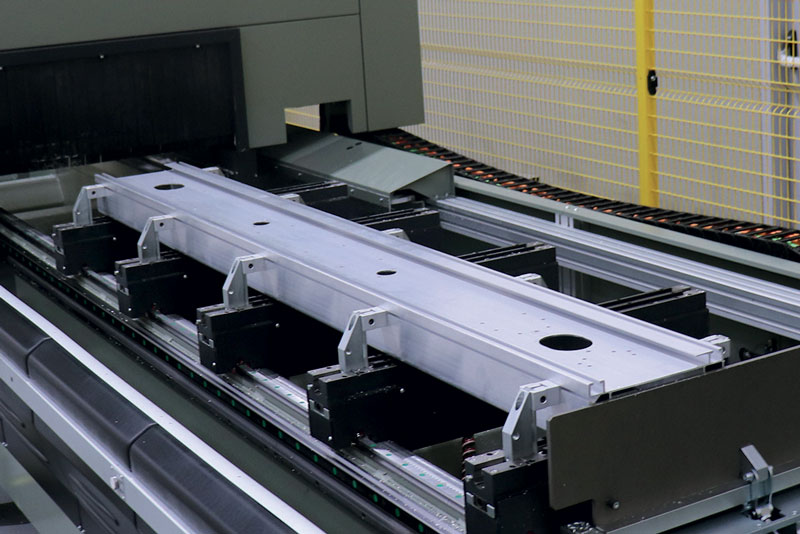

The machine is a brand new 2800 ton SMS Omav, equipped with all the latest technology. It has been in operation since 2019 and produces our entire range of catalogue profiles, which we previously purchased from other extruders, as well as new profiles requested by the market. The press is equipped with a double puller and forced-air cooling and can produce profiles up to a maximum size of 415 millimetres in width and 14 metres in length. The extrusion bench with Kevlar rollers, the ageing oven, the pressing machine and the whole plant have been designed to guarantee these characteristics for high quality extrusions. It is important to mention among our products the 415 millimetre single profile side bars of our own design, which are an important addition to our product range. It is significant to emphasise that with our plant, our previous knowledge and the creativity and flexibility which distinguish us, we are able to satisfy practically any type of request using mainly the typical 6060, 6063, 6005 alloys and their variants.

Aluminium rear doors for commercial vehicles from the Knock range have passed the 32-ton strength test (DEKRA certification)

Klever’s aluminium side panel struts. Practical and light, in more than 100 variations, they allow the side rails to be closed quickly and safely. Available in various heights, with the possibility of choosing between plastic or steel handles.

On which markets do you operate?

Historically, export has always been the main market for us. Before 2019, around 80% of our production was intended for export, especially to Germany but also to other countries in Europe and beyond. I still remember that in order to facilitate the distribution of our products abroad, we opened two branches: one in Ulm in Germany and the other, created in 2017 in the United States, in New Jersey, near New York. The two hubs are used both for the final assembly of products and as warehouses for finished products.

How are you organised for design?

As mentioned, we have hundreds of components in our catalogue which we have designed ourselves. The various products are usually supplied in assembly kits and we reserve the possibility of supplying spare parts after sale. In the production of our items, research and development is very important. For this reason, in 2018 we created within our group a new company, TKL, formed exclusively by engineers dedicated to the study and design of new solutions for existing products or for new developments. Precisely because of the nature of its activities, TKL cooperates with the Bari Polytechnic, which has been working with our Group for some time. The design process naturally requires compliance with the approvals necessary for the marketing of our products, which is why Takler has obtained, among other things, UNI EN 12642 XL certification for its doors. All the products we design and manufacture are subjected to specific tests by certified bodies, both in Italy and abroad; I would like to mention the most recent one carried out on Knock doors, which underwent a resistance test of 32 tons. Many of the solutions and articles we designed have been patented, and this makes us very proud as it is a guarantee of an important added value which we can present to our customers on the market.

You engage in a great deal of technical and informative communication; do you participate in international events?

We are currently developing new products which we shall soon be presenting at major international trade fairs. Recently, from September 30th to October 3rd, we were present in Germany at NUFAM Karlsruhe. From November 16th to 20th we shall be participating in SOLUTRANS in Lyon, and in 2022 from September 20th to 25th we shall be in Hanover at the important IAA international event. We are currently evaluating participation in other important trade fairs in Italy as well.

Let us conclude with a look at the future, at the outlook you envisage for the coming years, and at the development initiatives you have planned.

By definition, companies must think about the future and not just live in the present; for us, therefore, the paradigm of life is growth, a continuous dynamic in search of the best production and sales mix, from technologies to markets, internal organisation, Research & Development, and the inclusion of the company in the social context of the area in which it operates. For us, planning for the future of the company is an important part of everyday life. The case that provided the opportunity for this meeting is exemplary, namely the decision to enter the world of extrusion, choosing production autonomy to manufacture the products we present on the market. The Takler group has been on the market for just over 15 years. We are therefore relatively young, but we already have the right maturity to take new steps forward. The younger generation in the company, starting with my sons and all the employees, gives me the right enthusiasm to look to the future with new projects, new initiatives and new investments.