An adhesive for efficient lithium-ion battery assembly

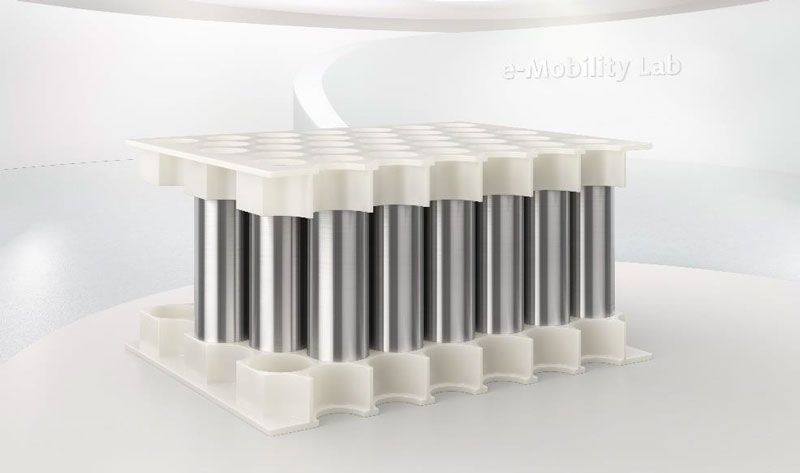

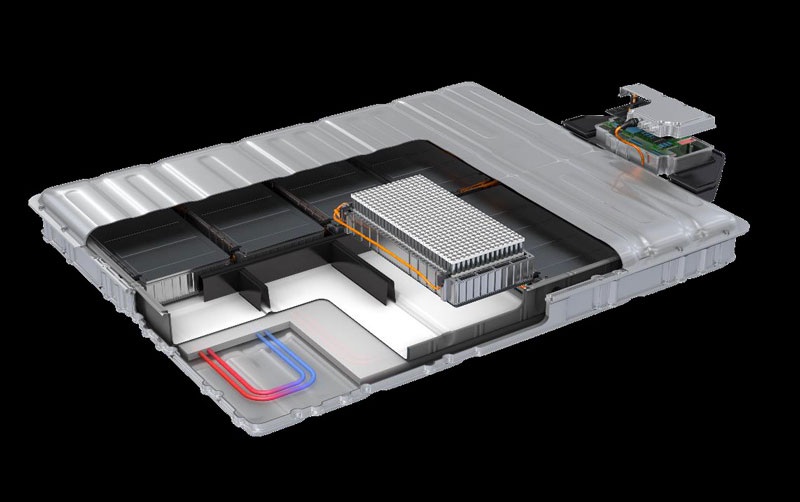

Covestro and Henkel as developed an adhesive solution for the assembly and fixation of cylindrical lithium-ion battery cells inside a plastic cell holder. This kind of battery are widely used for the construction of electric vehicles and they are all different depending on the manufacturer, but the performance targets are the same: longer lifetime, operational safety, cost efficiency and reliability.

This solution is based on a UV-curing adhesive from Henkel and a UV-transparent polycarbonate blend from Covestro; the material allows to construct dimensionally stable parts that are necessary for automated mass assembly.

For high volume automated dispensing techniques

The acrylic adhesive was formulated for use with the cell holder, which is constructed of a special flame-retardant plastic. It provides strong adhesion to the substrate material and offers production adaptability through long open times and short cure cycles.

With a strong consumer push to reduce electric vehicle prices, large-scale and cost efficient li-ion battery cell assembly is a prerequisite for every automotive OEM. As such, Henkel’s Loctite AA 3963 battery assembly adhesives and Covestro’s UV transparent polycarbonate blend Bayblend® were developed for compatibility with high volume automated dispensing techniques and offer flexible and fast cure mechanisms.

The cell holders are manufactured from Covestro’s PC+ABS blend Bayblend® FR3040 EV. With a thickness of only 1 mm, the plastic already meets category V-0 of the Underwriters Laboratories’ UL94 flammability rating but shows good permeability for UV radiation in the wavelength range above 380 nm.