New business models for mechatronics

Automating manufacturing processes is becoming imperative: automation brings sizeable benefits to end customers. Plant manufacturers are leading companies in this process, also creating new business models. We talked about this with Michele Merola, Founder of TMP Engineering and President of AIdAM, during the Assembly Week.

Let us start by explaining who TMP Engineering is. What does a plant manufacturer like you do? You are also the president of AIdAM, could you tell us something about this association?

TMP Engineering transforms and uses basic technologies and components to develop automated manufacturing processes. Our company was founded 11 years ago, at the height of the financial crisis: in my opinion, opportunities are hidden in moments of crisis. TMP Engineering was born out of a strong passion that my partner Andrea Perpiglia and I have for mechatronic automation. We founded the company in a bar, and at the beginning we didn’t even have the money to rent a warehouse. Today, fortunately, we have a structure of around 1,000 square metres, including workshop and offices. In our opinion, despite the concerns which there may be about the costs and challenges linked to the use of industrial automation technologies, companies cannot ignore the advantages they offer. Based on my experience, I can say that the automation of manufacturing processes basically has three objectives: to reduce labour costs, increase productivity and above all increase quality. Today these three key concepts represent the only element for companies if they want to remain competitive in the global market.

Moving on to my other role, in March 2021 I was elected President of AIdAM, the Italian Association of Automation and Mechatronics. There are many ideas and the initiatives we want to put in place are also many. We want the association to start talking to its members again and promote the various activities with them, so as to encourage the exchange which is at the heart of any association life. We want to involve not only manufacturers and integrators in AIdAM, but also the end users, because they are the ones who use the technologies, and they represent the first element of feedback on the advantages of process automation. Lastly, we are very keen on the topic of education, because if we do not invest in training, in a few years’ time companies will suffer a major shortage of technicians: it is already difficult even today to find people in a certain generation who are manually skilled with machines.

Let us explore the core business of TMP Engineering, what is the focus of the company, what types of machines do you build? With which sectors do you interface most? Are you tied to a particular name or brand, or not?

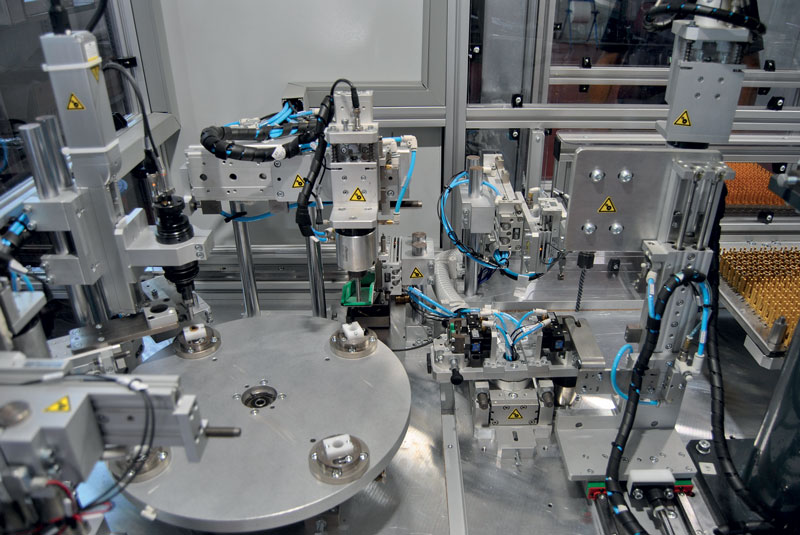

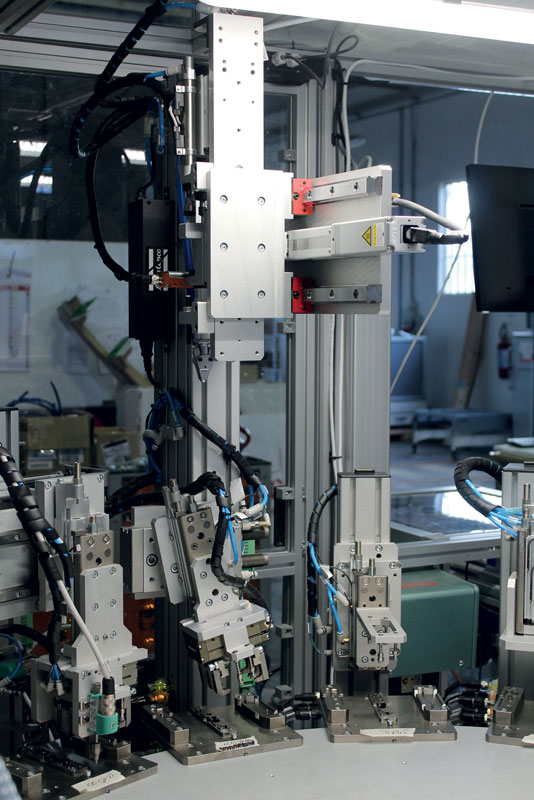

We build machines and systems to automate three types of macro-processes: the first is the world of assembly in general; the second is testing and inspection, that is, checking in the post-assembly phase that a component will meet the customer’s quality and functional requirements; the third is the handling sector, that is, the automation of material handling processes. Specifically, TMP Engineering is focused on the construction of semi-automatic and automatic rotary table and/or pallet line machines, with cycle times ranging from 1.5 s to 1 min. It is difficult to create a standardisation in terms of machine architecture, because we almost always have to customise it to the specific needs of the customer. We tend to make a line of semi-automatic machines, where there is a loading-unloading of components followed by an operator, while all other processes are carried out automatically; or, as a second alternative. we make fully automatic machines, where the operator’s intervention is limited to supervising and managing the plant.

The assembly processes covered by TMP Engineering are extremely varied: dosing, gluing, screw tightening, press-fit with force and displacement controls, electronic welding, laser and ink-jet marking, machine vision and so on. Our machines are gauged for products ranging from a few grams up to 20 kg, so we are talking about small to medium-sized items. As far as testing is concerned, we build machines which automate control processes for quality purposes or functional tests, according to the customer’s specific requirements for a given product. Even in this case, we are very transversal and therefore the technologies used are very wide. Finally, the handling sector, that is, the automation of intralogistics and material handling processes, is another very important focus for our company, and in chronological order it is also one of the most recent because we started investing in it about 4-5 years ago, and I must say with considerable success. The sector in which we operate most is the automotive sector: it is impossible for a special machine manufacturer not to work in this sector. However, we try to limit the weight of this sector on our turnover to a maximum of 40%, so as not to suffer too much from its downturns, while accepting not to follow its peaks. Another sector for which we carry out a lot of work is the electromechanical sector, especially manufacturers of switches and sensors in general; we are also present in traditional mechanics, working with manufacturers of bearings, gears and mechanical components. We have small market niches which we are trying to accelerate and push with innovations in the food and chemical-pharmaceutical sectors: in most cases these are multinational or very structured companies, which benefit from process automation because the numbers and production volumes are high.

We are not tied to particular brands, which can be an advantage in some cases, but sometimes we have to endure it passively: for reasons of standardisation, there are brands which are imposed directly by the end customer. In general, we have reference brands, but there are some that we work with more. In any case, we are interested in offering the best possible product for the specific application. No manufacturer has all the possible solutions for every need in its product range, so it doesn’t make sense for us to be tied to one brand. We therefore try to identify the best technology, sharing the choice with the customer: our design and construction process involves a strong interaction with the customer. We like to be able to offer the best to our customers, regardless of the brand.

How do you envisage your company in the future? How has TMP Engineering interpreted the concept of Industry 4.0?

In the last 2-3 years, we have noticed a paradigm shift on the part of our customers. Before, everything revolved around cycle time: increasingly performing and fast machines were requested. Today, the key words on which our customers’ focus has shifted, and in which we have invested, are: versatility, reconfigurability and convertibility of machines. To follow this trend, at TMP Engineering we have created a division which deals exclusively with automating handling processes using mobile robots. These systems allow our customers to automate handling processes which were unthinkable a few years ago, not only from an economic standpoint, but also from a technological point of view because they were difficult to approach due to technical limitations. The results have been excellent, we are in fact growing steadily in this sector and we have decided to invest in a unit, officially launched at the beginning of 2021, dealing exclusively with the development of collaborative systems.

We are focusing on certain types of industrial processes, because in this sector we want to launch a different paradigm for those who build special machines. We are used to making unique machines, which are very difficult to replicate: we want to change this by engineering the machines. We have defined typical applications, the first of which is palletising: we have developed a collaborative, plug & play system for the customer, which is therefore very easy to integrate into the industrial process, and which we sell off the shelf with certain characteristics, also offering a series of optional features which make the machine customisable. We have standardised certain types of components, for example we offer two robotics solutions and two PLCs. Regarding the optional features, we can add a seventh axis and have a full electric solution. We have therefore standardised the process, but some functions are at the discretion of customers so that they can adapt the machine to their particular needs.

In the second half of 2021, we shall focus on another ‘catalogue’ solution. We have devised an extremely flexible solution which we have called AMC (Autonomous Mobile Cobot), the combination of mobile robots with cobots to automate machine servicing and to give the possibility of flexible picking, that is, the picking of material from warehouses to automate the intralogistics process within the plant.

TMP Engineering customises the machine architecture to the customer’s needs.

An operational rental project with shuttles has been initiated for which, by setting a minimum fee, TMP Engineering is paid per kilometre.

To conclude our chat. TMP Engineering is offering new business models, such as the possibility of operational leasing. Could you tell us about it?

The idea of renting was born in AIdAM, during the celebrations for the association’s twentieth anniversary: Michele Viscardi, then President, focused the assembly on the theme of machine servitisation, that is, the possibility of renting also for assembly, testing and handling machines. I have been working in the company on this, and between 2020 and 2021 at TMP Engineering we have started two operational rental projects, one for palletising and one for material handling. We did not sell a plant, but we are paid per use. In the case of palletising, we are paid according to the number of boxes produced, at a figure agreed with the customer: the latter did not incur any capitalisation costs, but pays a fixed cost, or more precisely a cost which varies within ranges but which can be calculated in advance; if the machine does not work, the customer has no costs except maintenance costs. A very similar thing was done for a handling application: a fleet of shuttles operating on a system fully automated by us, for which we are paid per kilometre, establishing a minimum fee, just as if it were a rental car. In my opinion, this business model, which is already active in other sectors, represents the future as regards automation: obviously it requires a revolution in the supply chain, because everything must be integrated in a rental perspective, otherwise it becomes unsustainable. For the customer, the advantages and savings are clear from the outset, but there are also advantages for the manufacturer: it allows continuity of work, which is no longer linked to peaks, but provides a constancy which enables the production aspect to be better organised. We at TMP Engineering want to continue selling products, of course, but we also want to offer services.