SCARA Robots are equipped for Future Manufacturing Challenges

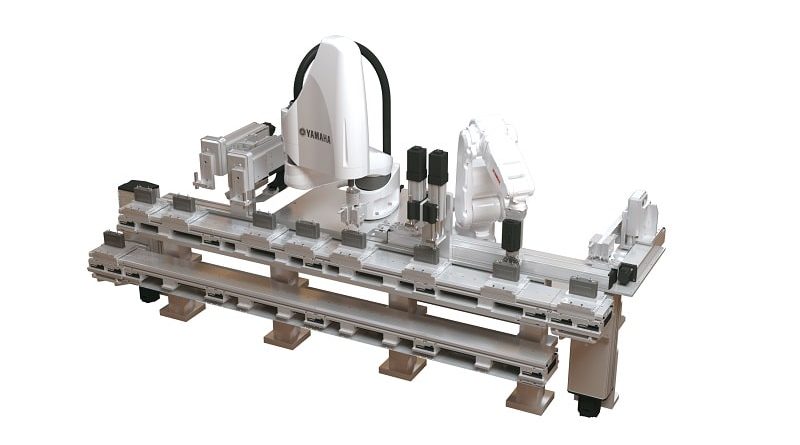

SCARAs are equipped for the challenges of the future: Yamaha’s YK-XE series is ideal for positioning and picking, boasting specified repeatability of ±0.01 mm in the X, Y and Z axes and ±0.01° in rotation. Yamaha SCARAs can also be combined with LCMR200 linear conveyors for flexible transport of semi-finished products.

The SCARA (Selective Compliance Assembly Robot Arm) robot is widely used in industrial automation projects. SCARA robots are a mature and affordable technology; they can be installed alone or in groups with other SCARA robots, or with different types such as cartesian, single-axis, and multi-axis robots. A closer look at the latest generations of SCARA robots shows how these machines continue to evolve to meet the demands of modern manufacturing.

Moreover, they combine well with Yamaha’s LCMR200 linear conveyor modules, which provide flexible workpiece transport. Unlike conventional belt-and-roller conveyors, these modules are programmed and controlled in the same way as other robots to create a fully integrated and coordinated robotic assembly cell.

Almost human arm

At a quick glance, today’s SCARA robots may seem little different from earliest generations of machines. Like their predecessors, the defining feature is a jointed 2-link arm that operates in a single plane. The SCARA has proved enduringly excellent at imitating the human arm: it can extend and retract, and rotate about the axis of both the “shoulder” and “elbow”, independently and simultaneously. It can move to an infinite number of locations within the envelope defined by the maximum extension of the two links, and can also reach inside enclosures.

Thanks to this flexibility, SCARA robots can handle a wide range of operations such as moving objects from one location to another, picking and placing or positioning components in assemblies, and executing processes such as screwdriving, dispensing, and engraving.

Ideal for positioning and picking

Great flexibility, accuracy and precision are further strengths that enable SCARA robots to tackle demanding industrial tasks and deliver high repeatability. Yamaha’s YK-XE low-cost, high-performance SCARA family, which handles payloads in the 4 to 10 kg range, contains models with specified repeatability as close as ±0.01 mm in X, Y, and Z axes, and ±0.01° in rotation. The YK710XE is an exception. With the greatest arm length in the family, reaching 710 mm, it has ±0.02 mm repeatability in X and Y axes.

The accuracy and precision of these robots allows use in tasks such as positioning tiny mechanical components like small springs or washers, or picking and placing surface-mount electronic components. Their payload capacity also allows them to be used for transfer or assembly of heavy workpieces such as automotive parts.