Robotics becomes a leading player even in secondary schools

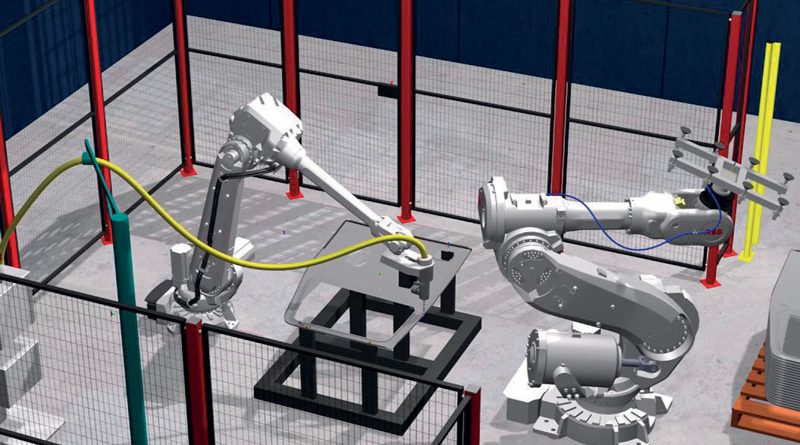

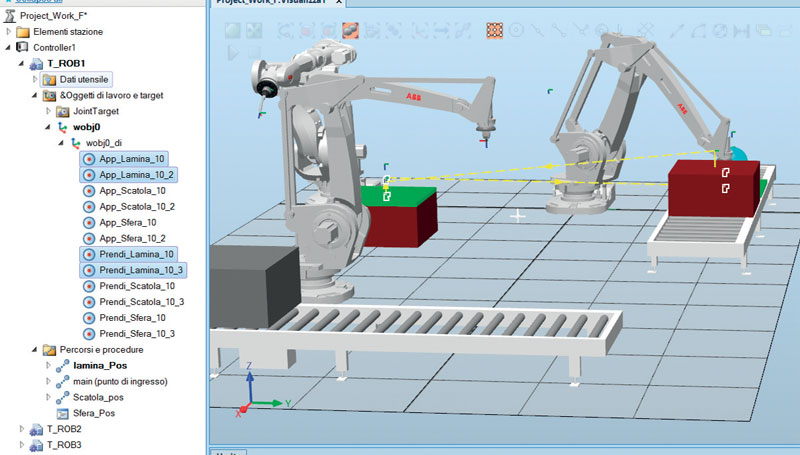

At the “Lorenzo Federici” secondary school in Trescore Balneario, a project work was carried out, proposed by Confindustria Bergamo in partnership with AIdAM, aimed at the students of the fourth classes for robotic programming. The students were able to practice and work with the “RobotStudio” software by ABB Robotics, with which they designed a robotic cell developed on three levels of difficulty.

During the past school year, the “Lorenzo Federici” Institute in Trescore Balneario, near Bergamo, was the stage of a project work carried out as part of a course on transversal skills and orientation proposed by Confindustria Bergamo to the fourth classes, one of the traditional scientific high school and three of the applied science section, in partnership with AIdAM, the Italian Association of Automation and Mechatronics.

The project was aimed to broaden the educational horizon and better reach new generations of students, strengthening the connection with an industrial context where automation is a major player and generates a growing demand for professional profiles. The project, which took place from February to May 2021, was divided into moments of general training and others dedicated to exercises and simulations, also involving the company ABB Robotics, for the use of the “ RobotStudio” software made available free of charge to schools, and downloaded onto the PCs of the students. All the various phases took place in distance learning mode, due to restrictions against Covid-19.

Enhancing creativity

During the course, the students discussed topics related to the introduction of robotic technologies and became familiar with the software. They then divided into groups, cooperating remotely, to apply the notions acquired in the simulated context of an industrial production environment. The input concerned the design of a robot cell developed on three levels of difficulty. The first level was aimed at programming a 6-axis anthropomorphic arm to move an object from a pallet to the conveyor belt; the second level was aimed at synchronising the robot’s movements with those of the conveyor belt; the third level was aimed at fully automating the production process from loading raw materials to the final palletisation.

A group of participants, after the initial briefing, tried their hand at writing articles about the experience, one of which was published on the online magazine Bergamonews. The students then presented the results during a dedicated event, where their strong involvement in a challenging experience emerged, which enhanced their creativity and problem-solving skills.