The opportunities of Digital Twin

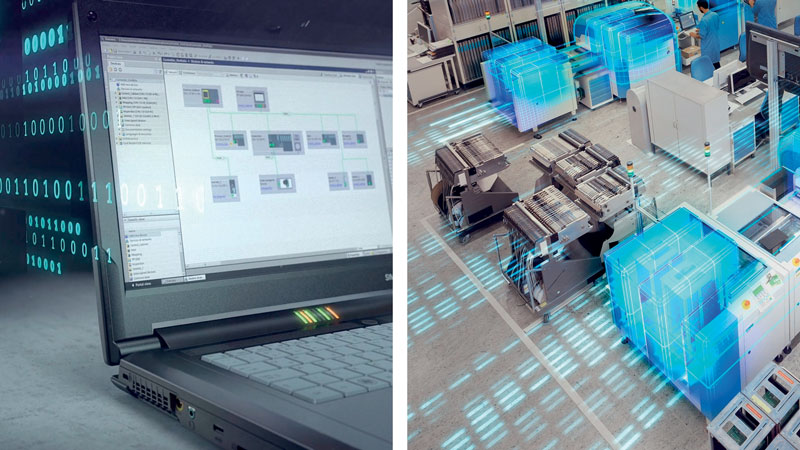

The digitization of manufacturing also passes through the creation and management of Digital Twins, those virtual representations of a product or process that make it possible to reduce development time and improve the quality of the product or process.

A Digital Twin is a virtual representation of a physical product or process, used to understand and predict the physical counterpart’s performance characteristics. Digital Twins are used throughout the product lifecycle to simulate, predict, and optimize the product and production system before investing in physical prototypes and assets. By incorporating multi-physics simulation, data analytics, and machine learning capabilities, digital twins are able to demonstrate the impact of design changes, usage scenarios, environmental conditions, and other endless variables – eliminating the need for physical prototypes, reducing development time, and improving quality of the finalized product or process. To ensure accurate modelling over the entire lifetime of a product or its production, digital twins use data from sensors installed on physical objects to determine the objects’ real-time performance, operating conditions, and changes over time. Using this data, the digital twin evolves and continuously updates to reflect any change to the physical counterpart throughout the product lifecycle, creating a closed-loop of feedback in a virtual environment that enables companies to continuously optimize their products, production, and performance at minimal cost.

The potential applications for a digital twin depend on what stage of the product lifecycle it models. Generally speaking, there are three types of Digital Twin – Product, Production, and Performance, which are explained below. The combination and integration of the three digital twins as they evolve together is known as the digital thread. The term “thread” is used because it is woven into, and brings together data from, all stages of the product and production lifecycles.

Benefits for design of new products

Digital Twins can be used to virtually validate product performance, while also showing how your products are currently acting in the physical world. This “product digital twin” provides a virtual-physical connection that lets you analyze how a product performs under various conditions and make adjustments in the virtual world to ensure that the next physical product will perform exactly as planned in the field. It doesn’t matter if you have complex systems and materials – product digital twins help you navigate that complexity to make the best possible decisions. All of this eliminates the need for multiple prototypes, reduces total development time, improves quality of the final manufactured product, and enables faster iterations in response to customer feedback.

Maximize the efficiency of manufacturing and production planning

A production Digital Twin can help validate how well a manufacturing process will work on the shop floor before anything actually goes into production. By simulating the process using a Digital Twin and analyzing why things are happening using the Digital Thread, companies can create a production methodology that stays efficient under a variety of conditions. The productio can be optimized even further by creating product Digital Twins of all the manufacturing equipment. Using the data from the product and production digital twins, businesses can prevent costly downtime to equipment – and even predict when preventative maintenance will be necessary. This constant stream of accurate information enables manufacturing operations that are faster, more efficient, and more reliable.

A tool to capture, analyze and act on operational data

Smart products and smart plants generate massive amounts of data regarding their utilization and effectiveness. The performance Digital Twin captures this data from products and plants in operation and analyzes it to provide actionable insight for informed decision making. By leveraging performance Digital Twins, companies can: create new business opportunities; gain insight to improve virtual models; capture, aggregate, and analyze operational data; improve product and production system efficiency.