A Platform for Remote Real-Time Monitoring

Spin-off of the Milan Polytechnic Institute, Miraitek develops and manufactures innovative and efficient solutions and technologies for factory and management process optimization. The Miraitek product portfolio includes scalable solutions for monitoring and in particular the Mirai4Machine platform, manufactured in compliance with Industry 4.0 standards, which makes it possible to receive information on the machine operating status and control in real-time the efficiency of the production plant.

Companies using Miraitek’s platform to monitor their plants have seen productivity improvements between 5% and 10%. Thanks to Mirai4Machine, it is possible to promptly detect any problems in production processes involving operations on the machine, identifying opportunities for improving production capacity. In addition, data history analysis and the implementation of machine learning algorithms enable predictive maintenance, which allows a further considerable increase in productivity. Finally, the integration of the Miraitek solution with maintenance management systems makes it possible to take action immediately in case of alarm and therefore minimize system downtime, allowing for an increase in production efficiency by up to 20%. The system flexibility and easy configuration according to the companies’ needs allow them to integrate it into their technological infrastructure, with no need to program additional pieces of software. “Typically, full system operation is achieved within two working weeks of the Miraitek team. The role of our consultants is not limited to configuration, but they provide continuous support. This, through the analysis of data collected by the plants, helps the customer to define optimal and increasingly productive operating models” says Sergio Cassinelli, General Manager at Miraitek. Mirai4Machine full configurability allow the customer to manage it in complete autonomy and be able to “shape” it at will, achieving a customized result according to their needs.

A complete diagnostic system

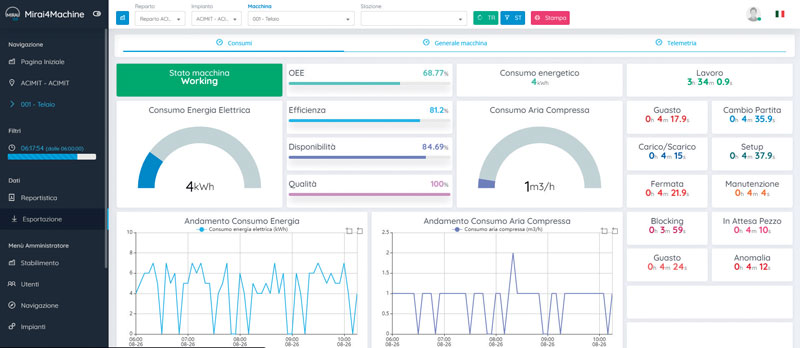

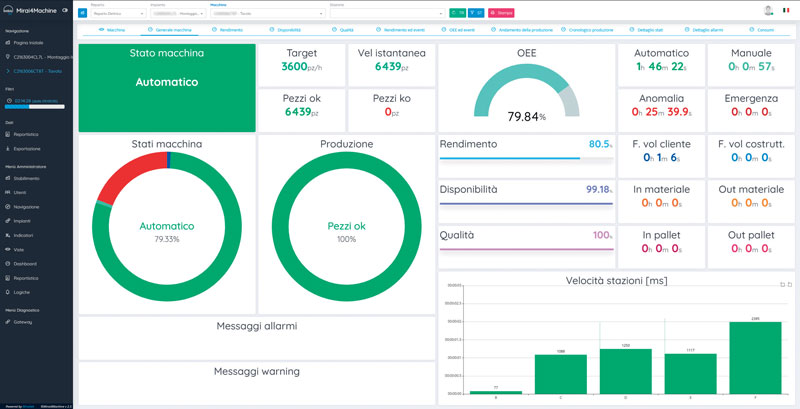

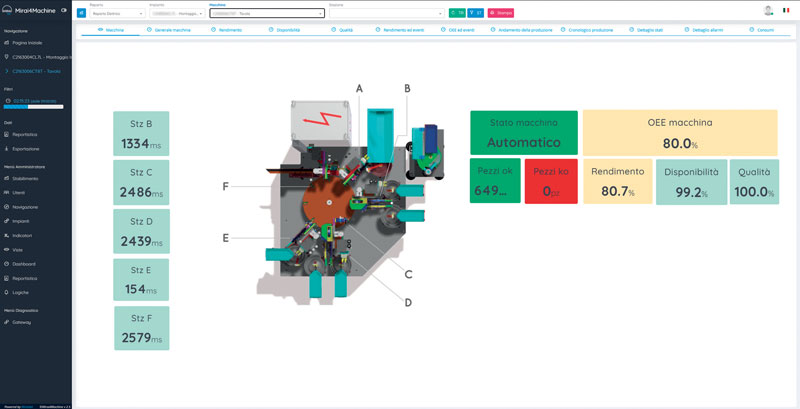

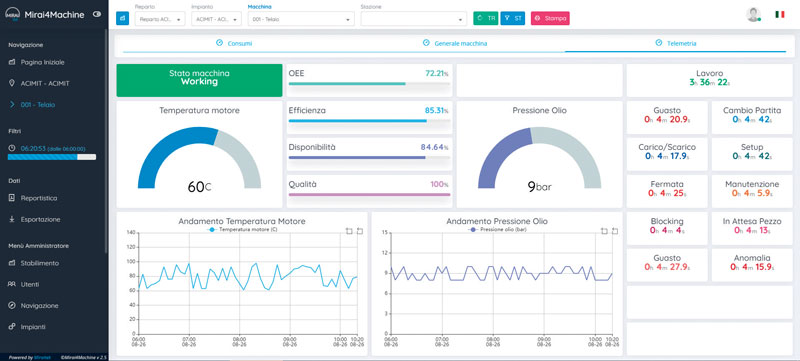

Through a simple and intuitive graphic interface, Mirai4Machine offers real-time indications, even remotely, on machine functioning (pieces produced, waste, speed, breakdowns, alarms, machine stops, etc.). In practice, a user-configurable rules “engine” makes it possible to associate specific actions to events such as alarms, faults, stops; events can be notifications or interactions with other systems (for example MES, MOM, etc.). Mirai4Machine also offers the possibility to analyze the data history and provides operating indexes such as RUL (Remaining Useful Life), OEE (Overall Equipment Efficiency). It works in parallel with management and production software, allowing a fundamental information exchange for the optimization of company’s production, decision-making and management processes. The system also offers features for energy monitoring, making it possible to measure in real time the electrical, pneumatic, hydraulic consumption of any system equipped with sensors for data detection and creating customized dashboards to show information in the most preferred way.

It is intended for machine manufacturers and manufacturing companies

Mirai4Machine is intended primarily for two types of market: that of industrial machine manufacturers and that of manufacturing companies with discrete process production plants. Specifically, machine manufacturers can secure a real competitive advantage by offering plant monitoring services to their customers and benefiting from the information gathered to improve the design and manufacturing of their plants. More in perspective, they can use the product to offer fee-based assistance and, in the medium and long term, implement “servitization” logic. Manufacturing companies with discrete production, on the other hand, can significantly improve their plants performance with the use of Mirai4Machine, which provides them with dashboards that normalize the information collected by machines from different manufacturers and make them usable in real time for those managing the factory.

A complete package of services

Miraitek’s offer goes beyond Mirai4Machine. “In fact – says Mr Cassinelli again – thanks to the experience gained also with the close collaboration with Milan Polytechnic Institute and selected companies operating in the manufacturing sector, Miraitek can offer a complete package of services. For example, it can provide support in assessing the degree of business process digitalization: an activity aimed at defining, together with the customer, a roadmap with targeted improvement actions. Another example is the technological and process assessment, which consists of a mapping of the customer’s plants and an analysis of production processes to highlight the critical issues and define improvement actions. The result of the assessment can also be used by the customer for the selection of software products or to define a configuration standard to which suppliers must adapt.

Finally, to make the most of Mirai4Machine potential, Miraitek provides not only installation and configuration services for plant monitoring, but also the possible integration with other customer solutions (ERP, MES, MOM) or with maintenance management platforms for automatic process triggering in case of plant failure. Added to this is the possibility of receiving advice for improving performance through the analysis of data collected by the plants and the correlation with other business processes, in order to define operating models that increase performance and improve customer profitability”.