A Project for a Zero-Defect Manufacturing

STREAM-0D project successfully come to an end, started in 2016 and aimed at developing a Zero-Defect Manufacturing solution: the main challenge was to allow industries to adjust the manufacturing processes in real-time, introducing smart decisions based on the forecast of simulation models. The STREAM-0D project has been conducted by a consortium of ten partners coming from seven European countries: three research institutes or universities, four SMEs, and three large industries that acted as end-users.

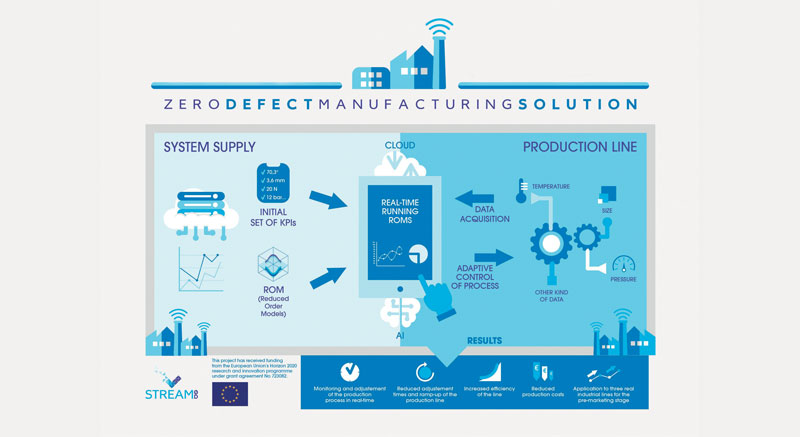

The European project STREAM-0D (Simulation in Real-Time for Manufacturing with Zero-Defects) for the development of a Zero-Defect Manufacturing (ZDM) solution officially ended on 30th September 2020, 48 months after its inception in 2016. STREAM-0D, which initially should have ended in March 2020, obtained an extension of six months due to the COVID-19 emergency: the extra months were useful for completing the activities on the production lines of the end-users involved in the project. STREAM-0D has received funding from the European Union’s Horizon 2020 research and innovation programme. The main challenge of the STREAM-0D project was to allow industries to adjust the manufacturing processes in real-time, introducing smart decisions based on the forecast of simulation models based on Reduced-Order Modelling (ROM) techniques and Data-Driven Models (DDM), which are mathematical models able to predict potential defects and failures based on machine learning algorithms.

Increase production efficiency

STREAM-0D’s primary goal was to increase production efficiency with high savings in time and costs, in order to shift the manufacturing process towards a ZDM approach. In detail, by the implementation of the STREAM-0D solution in the production line, manufacturers will be able to: monitor and adjust the production process in real-time through simulation-based control algorithms and data-based decision tools, so that the product performance indicators fit the target specifications; increase production flexibility by decreasing the time needed for the adjustment and of new designs; boost the efficiency of the line by achieving a reduction in rejected units and material; reduce production costs and increase production rates.

The STREAM-0D project has been conducted by a consortium of ten partners coming from seven European countries: three research institutes or universities, four SMEs, and three large industries that acted as end-users, making their production lines available for the application of the solution. In parallel with the technical tasks, the consortium also performed the activities that will pave the way for the future commercialization of the solution.

The results that came out of the implementation and demo tests of the STREAM-0D solution in the production lines showed impressive figures, with reductions in scrap rates, rejection rates, downtime, end of line tests and costs associated to these aspects well over the targets set at the beginning of the project. On the 8th of October 2020, the work and the results were discussed in front of the European Commission officer, during the final review of the project.