A total solution philosophy

HIWIN’s SCARA range of robots was born out of the company’s need to automate its production lines, which subsequently enabled it to acquire extensive know-how to pass on to the market and its customers. Gabriele Frasca, Application Engineer at HIWIN, talked to us about this, but also about anthropomorphic robots, during his presentation at Robotic Days on March 25th.

I would like to start by asking you to tell us about HIWIN’s approach to the robotics market and explain to us: what is your philosophy and what are the technological pillars that you promote by means of your product range?

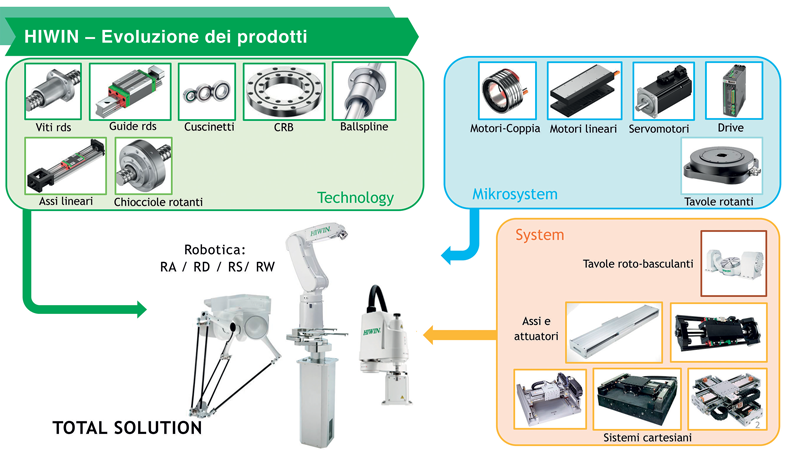

HIWIN started off mainly as a manufacturer of mechanical solutions for linear motion, supplying products such as linear guides and ball screws. Over the years, however, it has developed two other divisions: mechatronics, with linear motors, torque and rotary tables, and robotics, with anthropomorphic robots and SCARA, which have enabled it to embrace the total solution philosophy, that is, becoming a single supplier of complete solutions. To provide an example, our own robots have been designed with HIWIN products which are already widely used in the market. Our robotic line stems mainly from an internal requirement, namely the need for automation within our production lines. This has enabled us to acquire extensive know-how which we can pass on to the market.

Talking about the product range, I know that it is quite varied, ranging from anthropomorphic robots to SCARA. I would start with the latter: what kind of machines are they? What are their main features? But above all, for which market segments have they been developed? I am thinking, for example,

of automatic assembly lines.

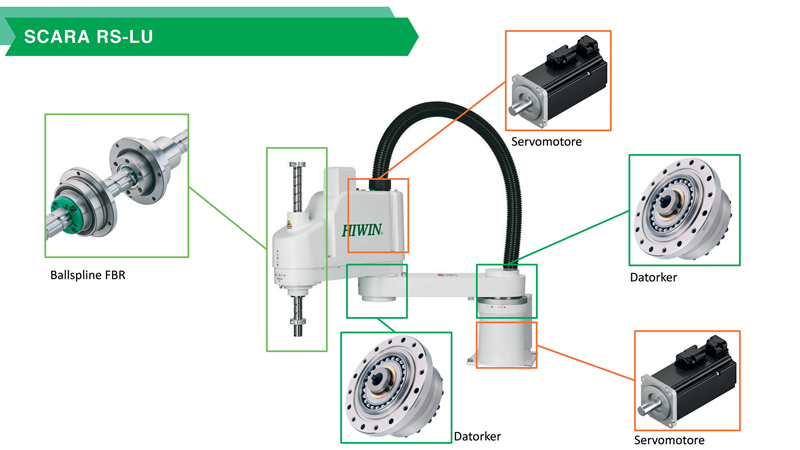

Yes, that is correct, our range is quite extensive. Our Research and Development department deals not only with anthropomorphic robots and SCARAs, but also with wafers and deltas. Starting with the SCARAs, these are planar 4-degree-of-freedom manipulators for handling objects on parallel planes with high precision and flexibility. They are particularly suitable for compact workspaces, and extremely easy to integrate into production lines with grippers, vision systems and linear motion modules. As I mentioned earlier, the key components of our SCARAs are made by HIWIN, and inside we can find Datorker harmonic reducers on the robot joints, and Ball Splines for vertical and rotary movement of the Z axis. In addition to the mechanical products, we also find the mechatronic range of servomotors inside the manipulator and the drives included in the controller. Depending on the applications in which the SCARA is used, we offer two different maximum wrist loads, 5 kg for the RS405-LU and 10 kg for the RS410-LU. As industrial robots, they have a very high positioning accuracy, with position repeatability down to 0.01 mm. In addition, depending on our customers’ needs and applications, different arm lengths and Ball Spline, that is, Z-axis depth, are available. These robots are mainly used for such applications as pick & place, packaging, assembly, quality control of materials in the pharmaceutical, electronic, mechanical and food industries.

Regarding industrial applications, your range also consists of two separate series of anthropomorphic robots with different wrist loads, could you tell us something about the specific characteristics and potential uses?

The so-called HIWIN anthropomorphic robots are 6-axis robots for complex movements with up to 6 degrees of freedom. As you mentioned, they have different wrist loads: the RA605 series up to a maximum of 7 kg and the RA610 series up to a maximum of 14 kg wrist load depending on the length of the arm. Repeatability is also high here, reaching up to 0.02 mm. This range is widely used in applications for the automation of machine tool and assembly machines servicing, parts handling in the packaging sector and simple surface finishing operations of complex geometries.

Speaking of application versatility, a key element is certainly the ease with which the robots can be programmed, what can you tell us about this aspect?

Both the hardware and the software of the robot controller were designed by HIWIN. As we are therefore the first users, we have developed a simple and intuitive graphic interface and programming language which allows the robot’s movement trajectory to be set in just a few steps. You can choose a teach pendant directly connected to the robot as a terminal, or you can connect from a PC to allow you to manage several robots with a single interface.

These days there is much talk about collaborative robotics and mobile robotics; could you explain what your construction philosophy is regarding these two particular segments of robotics?

The line offered by HIWIN is industrial, its characteristics being speed and positioning accuracy. Our accessories, such as electromechanical grippers, are well suited not only for the industrial sector, but also for collaborative robotics, as they are already in use and are officially compatible with the main cobot manufacturers.

Finally, may I ask you to look to the future and give us your definition of Digital Factory and tell us about the role which robots in general, and specifically HIWIN robots, will play within it?

The Digital Factory is something that can always be in motion. From a mechanical standpoint, robots can always adapt according to work requirements. Not only that, they must always be able to update themselves. This is why our robots are supplied with the possibility of interconnecting with the main factory management software. This is enabled by the presence of an HRSDK library which allows the remote control and monitoring of our robot via an Ethernet cable. It is also possible to use one of our remote control programs to monitor the condition of the robot and provide new instructions according to production needs.