Robotic Bin Picking with a Smart Vision

Very often it is difficult for a robot to identify irregularly shaped, and perhaps transparent, objects in a container because of their inaccurate shape. The solution by Photoneo, partner of Advanced Technologies, addresses this problem with a bin picking solution based on artificial intelligence capable of handling such complexity and allowing the robot to pick up transparent plastic bags effortlessly.

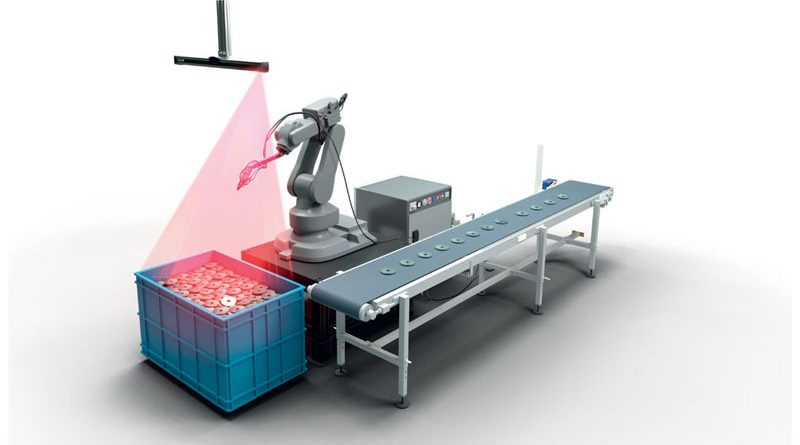

Bin picking, that is, the robotic detection and picking of randomly arranged objects within a container based on CAD models, is an increasingly common application that occurs in challenging industrial environments. There are objects which are difficult to detect and grasp in bin picking, but Advanced Technologies, thanks to state-of-the-art partners, is able to select the most performing and reliable technology according to customer requirements. Photoneo, a brand distributed by Advanced Technologies, decided to use the experience, knowledge and capacity gained over the years to further enhance the performance of its 3D reconstruction solutions with the aid of artificial intelligence and thus teach the system to detect and pick up bags. Bin Picking Studio is an all-in-one picking solution for robotics integrators, which does not require prior machine vision knowledge to configure it. Its robust features have enabled it to enter practically all industrial sectors: automotive, manufacturing, logistics.

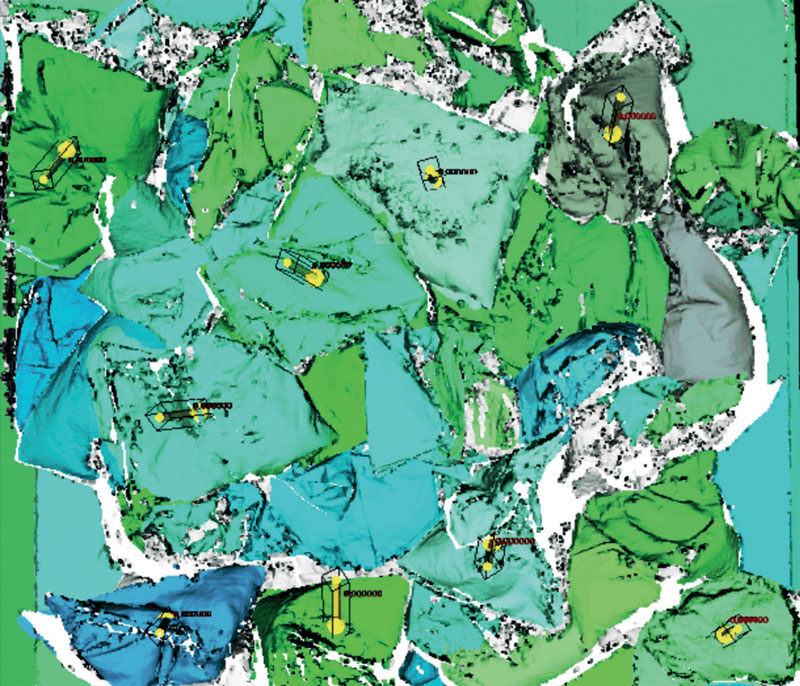

However, some customers are looking for a solution allowing them to pick up irregularly shaped objects in random positions inside the box. Thanks to sophisticated algorithms it is possible to locate and select objects of different sizes, various textures and arbitrary shapes, including deformations. Moreover, the objects do not have to be stacked according to ordered patterns, but can be positioned in an absolutely random way: the robot is able to recognise and grasp them.

Even better than the human eye

Artificial Intelligence solutions enabled by a combination of 3D vision and advanced algorithms have shown the world the opportunities for the automation of materials handling, production, logistics and much more. And it was logistics which proved that there was one last gap left to cover all types of objects and applications: goods are not always transported in solid boxes, but some come in sacks. These represent a challenge for automated sorting because they do not retain their shape: they are flexible, irregular, easily deformable and therefore very difficult to locate. Recognition of the boundaries between bags chaotically placed in a container can often be difficult even for humans. The task becomes even more complicated for transparent bags. Photoneo developed a network which can recognise bags, even better than the human eye. They may overlap and prevent each other from being picked up, but the system is able to handle this complexity through optimal 3D reconstruction quality, allowing the robot to pick up fully or partially covered bags. Another common difficulty derives from the nature of the material the bags are made of: they are full of creases and wrinkles which often make them fall out of the gripper immediately after they have been successfully detected and lifted. For this reason the advice is to use a suction cup grip with feedback to avoid unsuccessful gripping and reduce the failure rate. The AI-based Photoneo Anypick and Universal Depalletizer solutions are now smarter than ever before.