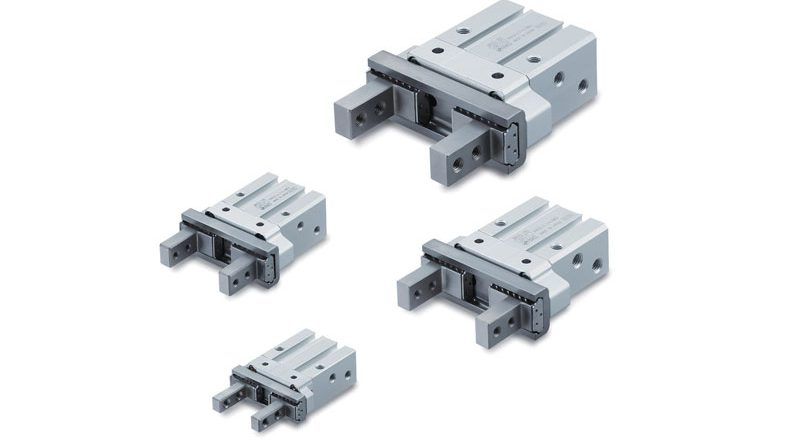

Compact parallel pneumatic gripper

SMC faces the challenge of speed and precision represented by the increasing use of robotic arms on production lines with the compact parallel pneumatic gripper JMHZ2.

The new JMHZ2 compact parallel pneumatic gripper has been designed to improve grip point and productivity features. With the same diameter as its MHZ2 counterpart, JMHZ2 is up to 21% shorter in length and up to 43% lighter. The maximum gripping point is increased, thus avoiding interference between the gripper body and the machine. Thanks to the low inertial loads, the robotic arm moves faster reducing cycle times and significantly improving productivity. In addition, it has a high rigidity and repeatability of ± 0.01 mm thanks to the integration of a linear guide and fingers within a single piece.

“Today’s machines are becoming smaller and lighter and the components must be inserted in the limited space available” – says Roberto Rubiliani, Product Manager of SMC Italia. “The JMHZ2 pneumatic gripper has been designed to meet this need. With the integration of the linear guide, which is not usual in this type of gripper, we are sure that JMHZ2 will add valute to the J series”.

To offer greater flexibility, the JMHZ2 gripper has three mounting options on two sides and is supplied in four diameters: Ø8, Ø12, Ø16 and Ø20. It is the ideal solution for handling small pieces that require a long gripping point, robot gripping hands, light piece transfer and pick & place applications in small spaces.