Delta robot

The motion plastic specialist igus, whose Italian subsidiary is celebrating its 25th anniversary this year, presented a brand new delta robot at Automatica 2018. The robot is made of three ZLW drylin belt linear actuators, double igubal joints and adapter plates, all elements that do not require maintenance or lubrication. The stepper motors with encoder guarantee rapid handling with an accuracy of ±0.5 mm up to 1 kg of load.

The complete system has a 420 mm reach and can handle up to 5 kg by adjusting its speed. The lightweight aluminium and plastic frame allows speeds with pick rates of at least 60 strokes per minute.

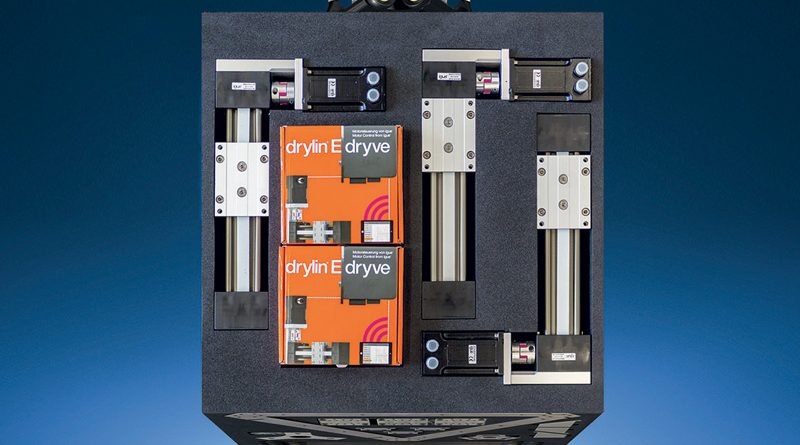

According to the customer’s requirements, the new delta robot can be delivered within 24 hours as a pre-assembled kit with assembly instructions in an 18 kg box or as a ready-to-install system mounted on an aluminium transport frame. The customer can choose between his own software and control system or the intuitive and easy-to-use dryve D1 control system. The delta robot is ideal for simple handling, pick & place tasks as well as inspection and testing applications.

In addition to the delta robot, igus also provides additional low-cost robots within its robolink product range, allowing six-axis robots of up to 5 degrees of freedom to be assembled with a modular system made of couplings with different sizes, motors and connection axes.