Easier Automatic Pick & Place thanks to Linear Robots

igus presents its drylin series, linear and room linear portals designed for end-of-line processes. Both versions can move loads up to 5 kg, within a space of 800 x 500 mm for the linear gantry and 800 x 800 x 500 mm for the tri-axial. These igus’ portals represent a valid, simple and fast automation solution, which requires little programming work.

by Maria Giulia Leone

igus has expanded its range of cartesian portals drylin series and developed two new versions, linear and room linear, for larger working spaces than previous versions. This choice was dictated by the fact that in many sectors, from sorting lines to medical technology, cartesian robots are becoming more and more widespread in companies that choose to automate pick & place tasks, looking for solutions that are quick and easy to integrate. For some time now, cartesian robots have been an advantageous choice for companies, both large and small, who need to adopt automation solutions that allow them to return on their investment in a short time: with their help, users can carry out their tasks economically, easily and quickly, in fact, only a small programming effort is required.

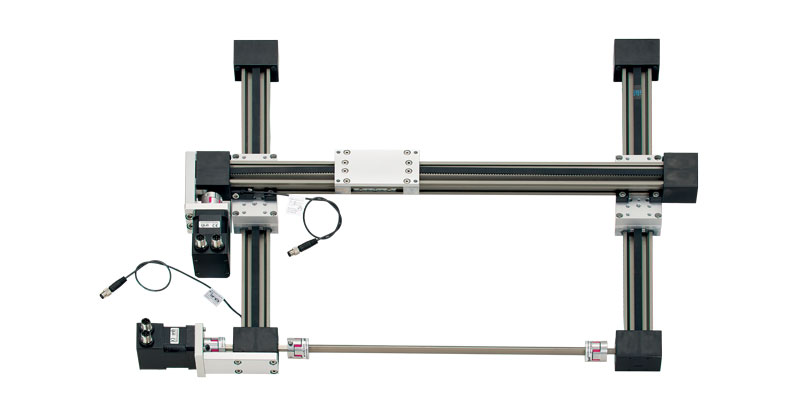

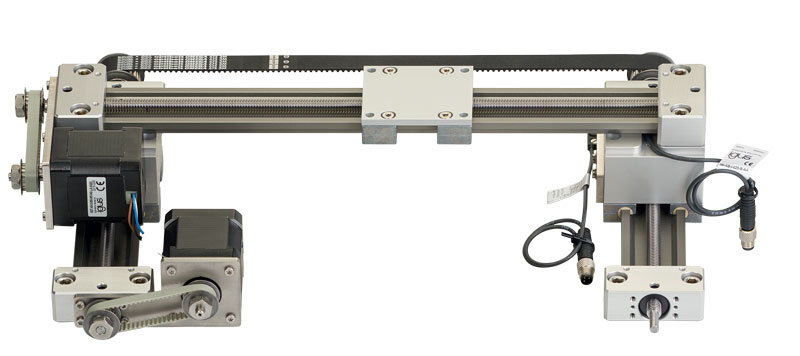

The two new kinematics systems allow users to move up to 5 kg. Both linear robots are available directly from stock. They can also be customised to suit the customer application in question. In addition to the stock items, users can assemble their own linear robot with strokes of up to six metres and request a quotation from igus. Depending on customer requirements, axis length and various motors can also be configured with such items as energy chains and cables from igus. Starting with its lubrication-free linear axes, igus has developed linear robots with different assembly levels. Depending on the application’s requirements, two-axis X-Z or X-Y robots and three-axis X-Y-Z linear robots can be selected. igus introduced a linear robot and a linear room robot with an enlarged workspace, which allows users to move even greater loads across an even larger area.

Ideal for sorting pick & place and bin picking

The two linear robots consist of pre-configured linear modules, aluminium linear axes, NEMA stepper motors and encoders. The line robot can transport loads of up to 50 N in a workspace of 800×500 mm at a maximum speed of up to 1 m/s. The new room linear robot is a good option for more complex tasks. The linear room robbot can transport loads of up to 50 N in a workspace of 800x800x500 mm at a maximum speed of 0.5 m/s. Two ZLW toothed belt axes and one GRR gear rack axis ensure precise guidance and lubrication-free operation.

The new linear robot solutions are used in pick and place, bin picking and sorting tasks. Most of these processes have been moved to the end of the production line. An example is its application at SSI Schaefer, intralogistics specialist. The new drylin room linear robot automated the provision of sensitive products using a transport box with a thermoform insert. The specially developed packaging and the use of a linear robot allowed various coloured handles to be pre-sorted for the production of a household appliance. There are other linear robot use scenarios in microelectronics and automated testing.