Reaping the benefits of robotic automation

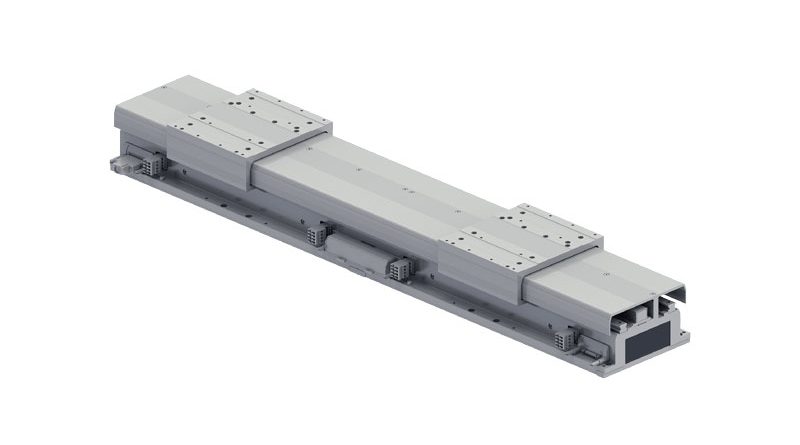

The modular robotic linear conveyor LCMR200 proposed by Yamaha can replace traditional conveyors as it is easier to program and can increase productivity also thanks to the absence of mechanical end stops. It is a great way for companies to start taking advantage of the advantages of robotic automation.

Many production lines are staffed by human workers, performing processes on workpieces supplied by a conveyor belt. Increasing the conveyor speed should feed the workpieces more quickly and enable increased productivity, but often this is not the case. Productivity can be reduced as the result of increasing the conveyor speed. Robot technology can help overcome this problem. Linear robots can replace conventional conveyors and are easier to program, with digitally-defined start and stop locations with no need for mechanical end stops. Acceleration and deceleration happen smoothly within pre-defined distances, allowing fast transit speeds. Moreover, the flexibility to move in forward and reverse directions opens new opportunities to achieve even greater efficiency.

Yamaha has enabled several customers to take advantage of such benefits by integrating its LCMR200 robotic linear conveyor module into production lines. This model is fast, efficient and also less demanding of workflow reorganization than arranging multi-axis articulated cobots. This modular, linear robot can provide a convenient introduction to the potential for robot process automation, which can extend from simple replacement of a conveyor or indexing table to full end-to-end process automation in a guarded robot-assembly cell.

A comprehensive selection of industrial robots

When it is required to create a complete robotic automated process flow for building small products such as loudspeakers or automotive modules containing several constituent parts, solution integrators often need to combine robots of various types to perform all the individual assembly actions cost-effectively and in a space-efficient footprint. To assist, Yamaha has a comprehensive selection of industrial robots in all commonly used types from the modular LCMR200 and other single-axis robots to cartesian and SCARA robots. These give solution integrators all the options they need to create an efficient workflow even when factory floor-space is tight, while also taking into account important considerations such as maintainability, programmability, and ease of use.