Gasketing for automotive industry

Henkel has presented Loctite AA 5884, a new polyacrylate gasketing technology for automotive industry, with higher oil resistance and proven lower gas permeability. This new gasketing makes it possible for costumers to enhance the performance and reliability of their products, all while achieving productivity goals and reducing overall costs.

The new polyacrylate gasket material has an excellent resistance against oil and ATF fluids and dose not promote oil foaming.

Resistant to temperature, pressure, and micro-movement

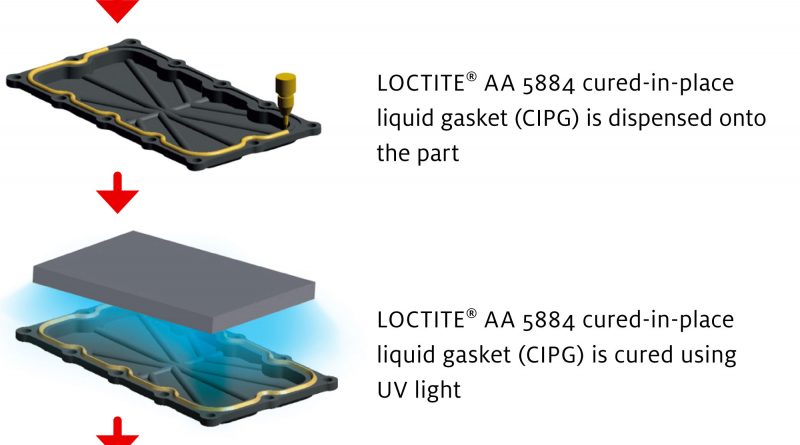

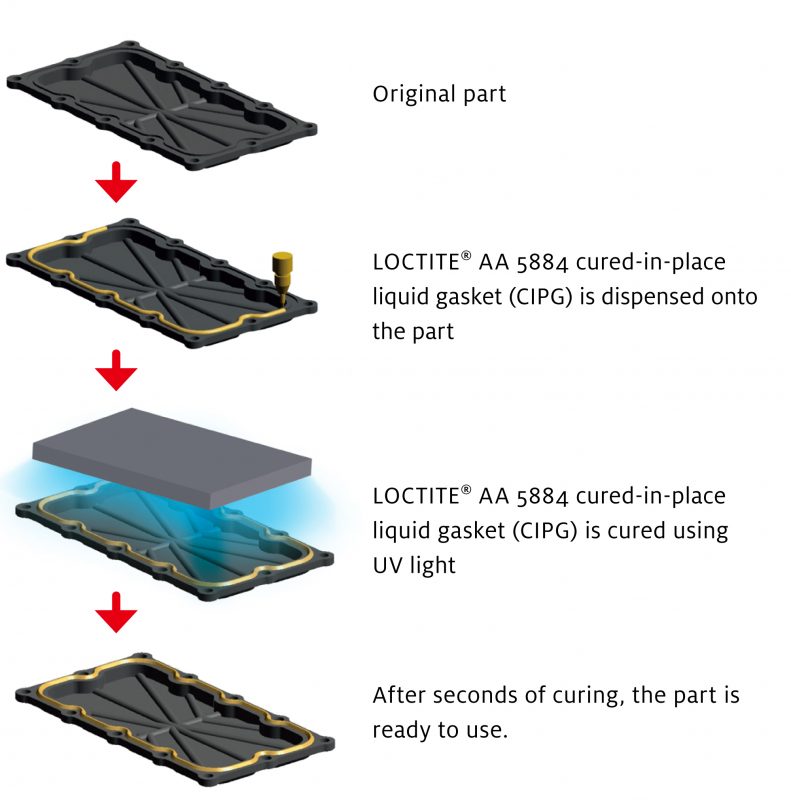

These static gasket materials are positioned between two flanges which are held together by fasteners to prevent the leakage of fluids and gases, by closing the gaps between these surfaces. In order to keep the sealing function and a leak-free joint for a prolonged period, the gasket must be resistant to the medium being sealed. At the same time, it has to be capable of withstanding the application temperature, pressure and micro-movement of the joint. These gaskets are formed by applying a bead of liquid elastomer by using automated high-precision equipment.

The liquid gasket is cured by ultra-violet light within seconds and becomes a solid compression gasket with no knit line. This reduces the risk of re-work and leakages while improving the productivity. It also lowers the overall cost by automating the gasketing process and eliminates the inventory and the complexity of the PIP solid gaskets.