Growing Through a New Market Approach

Luca Zerbini, who has been leading Misumi Italia for less than a year, told us how business strategies are changing, becoming increasingly oriented towards consulting activities in terms of total cost saving. What does not change, for the Japanese manufacturer, is the centrality of a sector, that of assembly machine manufacturers, more and more focused on flexibility and in search of technologically advanced precision mechanical components, also reliable and customizable.

by Fabrizio Dalle Nogare

A smooth sea never made a skilled sailor, says the quote. Perhaps Luca Zerbini thought this when he found himself, just under a year ago, at the helm of Misumi’s Italian branch. In fact, he was appointed Branch Manager when he was the Sales Manager for Lombardy and Italian-speaking Switzerland, in a time of economic uncertainty.

“The fact that I started the new job in quite a hard time is certainly challenging”, says Mr Zerbini at Misumi headquarters in Milan. “Speaking of machine manufacturers, which are our main business, we do not see a particular slowdown in terms of production. We rather see a decrease in the order volume, with some projects that have been postpones but which, we believe, will sooner or later be unlocked. As a matter of fact, Italy is into technical recession and this leads to some consequences as for industrial production”.

The role of the Italian branch between changes and relationship with customers

Misumi is a Japanese manufacturer of mechanical components, precision tools, industrial materials, highly specialized in micro-mechanical components for industrial automation. The Italian branch, inaugurated at the beginning of this decade, has a strong link with the German headquarters, which in Frankfurt rely on a very well-equipped hub. Here, quite significant investments are being made on automated warehouses. “The Italian branch makes about 10% of European turnover”, says Misumi’s Italy Branch Manager. “Especially in the last few years, we have become an important benchmark for the Group’s European strategies. Our ability to keep good relationships with our customers over time is highly appreciated”.

In a time of great change in the dynamics of production, Misumi considers service as a key element within the company’s strategy. “Service is absolutely crucial for our business. The products we manage are relatively simple, however they can be found in virtually all automatic machines. Regardless of the components’ technological reliability – an aspect that Misumi, like Japanese companies do, has always looked after, and this is acknowledged indeed by the market – we believe it is necessary to have the right structure in order to provide top-notch services. For example, the fact that we do not require minimum order quantities helps us to show quite a positive attitude towards our customers. Then, we are strongly focused on keeping a user-friendly and efficient e-commerce platform that may allow engineering departments to configure components directly on the web portal. In fact, Misumi makes it possible to customize the components, which are manufactured at our Asian production plants and delivered on time: 99.7% of all deliveries indeed meet the deadlines. Quality repeatability and on-time delivery are key elements in our sales strategy”.

More than a sales branch: the focus shifts on total cost saving

The focus on e-commerce is joined by a sales network capable to handle a very broad range of components and, above all, a diverse customer base, including both large and small companies. “The growth process of Misumi Italia also passes through a major change”, continues Luca Zerbini. “From people who sell components and systems, we now act as true total cost saving consultants. We actually emphasize this concept quite a lot, as it is the sign of a significant change of approach. All this allows us to be able to talk not only to engineering departments, but also to those business figures – such as supply chain managers or even owners, in case of the SMEs – who have a broader view in terms of investments as well as indirect costs within their organizations”.

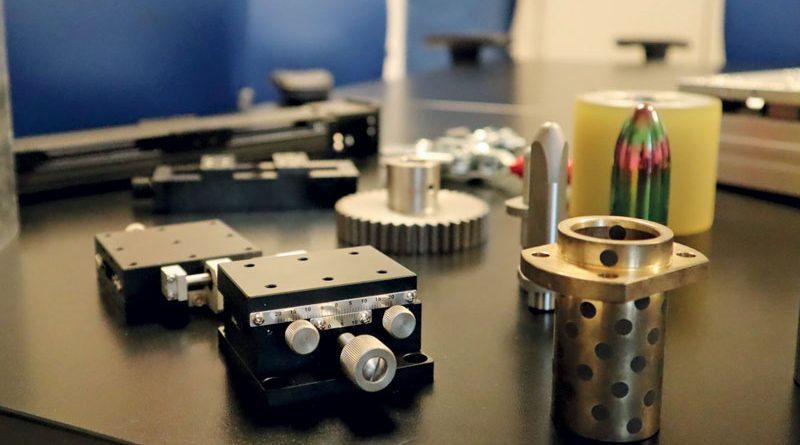

Due to the features of Misumi components, along with the packaging industry, the assembly and special machinery sector is central to the Japanese manufacturer’s business. “If we think of products such as positioning or centering systems, precision shafts or slides, special machine manufacturers can find the components that fit their needs within our catalogue. In fact, Misumi is able to provide pieces that are finished, coated and equipped with the desired characteristics in terms of size and tolerances. When the machines are designed practically from scratch, as it happens in the assembly sector, customization is a key factor for manufacturers, along with the possibility to rely on technologically advanced products, whose choice, in short, is not primarily based on price”, adds Mr Zerbini.

Customization and flexibility

The features of Misumi components are suitable not only for automatic machines. They also fit robotic cells, which often work alongside assembly lines. “Centering or positioning pins, but also components for machine tending, are very important as for robotic cells”, confirms Luca Zerbini. “This idea is even more true nowadays, in a time characterized by smaller and smaller production batches. This results in the trend, showed by manufacturers, to design highly modular machines and lines, in which the single parts of a line are designed to be added or removed according to the peculiarities of the specific application or product to be assembled”.