Much More Than Just Motion Control

At SPS in Nuremberg, scheduled at the end of November, Aerotech will launch the “Automation1” control platform, which functions as a complete machine control with all components, thus supporting the markets of precision machinery and motion control in general. Among the brand-new products from the US specialist are also ALAR-XP high-precision rotary tables with direct drive, with excellent speed and positioning accuracy.

by Franco Parrino

Aerotech, a company specializing in motion control and positioning systems, is about to take part in the next edition of SPS, the leading trade fair for industrial automation scheduled in Nuremberg from the 26th to the 28th of November.

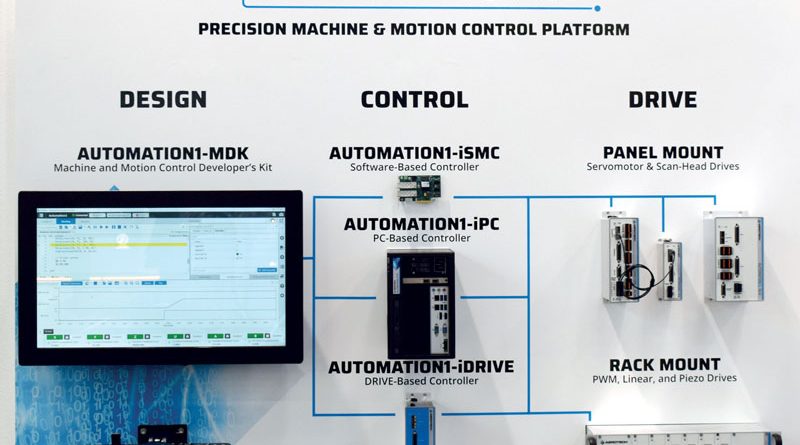

The flagship of the US company’s participation will be the “Automation1” control platform, which, among other things, demonstrates in a demo system force regulation with the ACT115DL linear high-performance actuator. The motion control platform functions as a complete machine control with all components and thus offers much more than a pure “motion control”.

Aerotech systems and associated software solutions are used wherever high throughput is required with absolute precision. “High-precision control of motion components has been our know-how for decades. Whether in the industry or in research facilities, wherever something in the micro and nanometre range is to be repositioned accurately, our solutions and systems are used”, explains Norbert Ludwig, General Manager of Aerotech GmbH.

A simpler positioning system control

Anyone who uses an optimised control platform reduces the non-value-added development effort and can sometimes supply their customers faster. “With Automation1, we have brought the control of positioning systems and connected components on a platform that is specially equipped with a new software-based motion controller”, adds Norbert Ludwig, underlining the main advantage over previous solutions. “We can drive servo and stepper motors, galvo scan heads, piezoelectric actuators, and a variety of other devices. The drives are connected via the HyperWire bus, the most powerful communication bus in the motion control industry”.

At the exhibition stand, Aerotech will use a concrete example to show how the force control can be set up and used with Automation1. For this, the linear high-performance actuator ACT115DL is installed in combination with a force sensor. It will be demonstrated how the rigid mechanical structure of the linear actuator enables excellent dynamic performance with significantly reduced settling times.

Since the non-magnetic rotor is cogging-free and has sufficient power, extremely uniform speed, position and force control can be ensured. This is of great advantage, among other things, in die or chip bonding, pin insertions and test applications.

An ideal platform for automation systems

The new Automation1 platform supports today’s growth markets for precision machinery and motion control, and is particularly well-suited for automation systems, precision laser processes, test and inspection processes and other applications where process control is closely linked to motion control. Thus, the new control and drive development offers even greater optimization potential for faster motion and settling times, better position stability and increased contour accuracy. According to Mr Ludwig, Automation1 is “the future of motion control. It is the first motion control development environment that simultaneously puts years of user experience with the latest technology for precise and fast motion sequences into the forefront of product design”.