Reliable and Interconnected e-Chains

The innovations promoted by igus in the field of e-chains are manifold and quite significant. From the “lokchain” energy chain with extending and retracting pins to increase the operational reliability, up to the introduction of QR-codes on the e-chains. Such an Internet-based technology indeed offers easy part identification, procurement and assembly instructions. A smartphone or tablet camera is needed to scan the QR-codes.

by Cesare Pizzorno

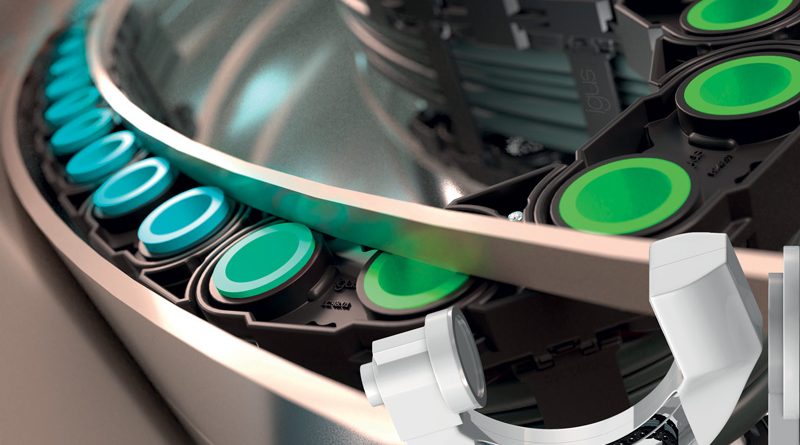

The motion plastics specialist igus developed the “lokchain”, a new concept consisting of an e-chain with automatically extending pins and a compact guide trough for the dynamic guidance of energy chains. This allows hanging, vertical or side-mounted use of the system with or without lateral acceleration. Even long travels with a moving lower run are possible by fixing the lokchain in the upper run trough. The system can also be used in vertical circular applications.

Automatic locking pin system

The basic principle of lokchain is quite simple: pins integrated into the side links hold the energy chain firmly in the guide trough. When the chain link is bent into a radius, the pin retracts automatically and releases the chain from the guide. When the chain link comes out of the radius and engages the trough, the pin extends and automatically secures itself back into the trough.

This eliminates the need for more costly guide trough systems. In this way, the machine builder saves money.

Due to the special construction of the lokchain there is hardly any abrasion and wear, so the service life of the e-chain is increased. The prototype proved its durability successfully in an endurance test carried out at igus laboratory. Another advantage of the new e-chain system is the mobility of the chain links. They ensure that the energy chain operates safely and quietly, even with small bending radii and over long travel distances.

Energy chains with QR-codes to get information more easily

From purely mechanical products up to an online calculable and networked machine component: igus continues to digitalise its tribo-products and now equips its energy chains with a QR-code. Integrated directly into the e-chain, it offers the machine builder online information about the chain, including assembly instructions, or how to identify and order spare parts, with just a quick scan using a smartphone or tablet.

This connection of the “offline” and “online” worlds has a very tangible benefit for the machine builder: faster information, easier assembly and spare part procurement via the Internet.

Simplified assembly instructions

To use the code, the engineer uses a smartphone or tablet camera to scan the QR-codes, which are located on the crossbars and side parts. The engineer is directed to the online portal, where igus provides all the important information about the product. These include photos and videos that show the engineer assembly instructions. Important assembly steps are shown in slow motion for better understanding. This helps engineers reduce set-up times and simplify initial installation. The QR-code also simplifies the process for ordering spare parts for energy chains. Intuitive illustrations on the website help the engineer to understand the structure of the igus part numbers and to recognise the different components. The online shop is just a click away, where an order can be placed. And the components are dispatched for delivery from 24 to 48 hours later.