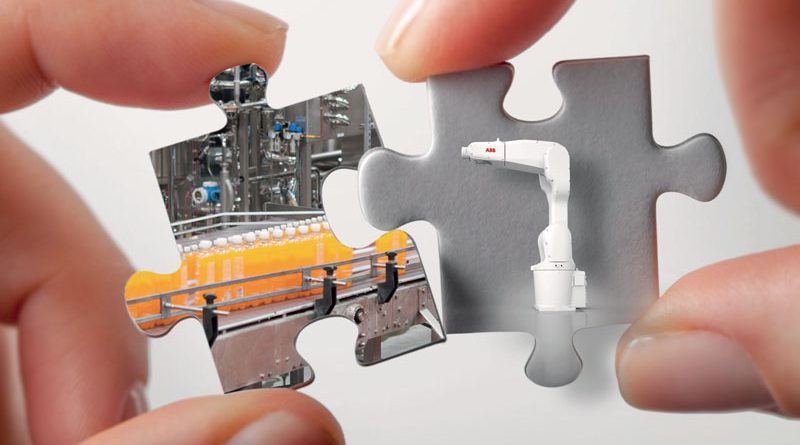

Robots and Machine Automation: an Integrated Solution

B&R and ABB propose a solution that integrates robots and machine control systems, which eliminates the need for separate controllers and panels, reducing complexity and allowing synchronization between robots and the machine’s parts.

di Marta Bonaria

B&R, as part of ABB’s Robotics & Discrete Automation business, introduced ABB robots as an integral feature of its automation landscape. Machine builders can buy robots and their machine control system from a single source. B&R is also among the first to launch a comprehensive portfolio for open, real-time capable OPC UA over TSN communication.

Integration of ABB robots into the B&R automation system eliminates the need for dedicated robotics controllers, separate control cabinets and programming specialists. The new solution reduces complexity and optimizes synchronization. Customers benefit from good precision and user-friendly programming.

Standard for making modular and adaptive machines

B&R presents a comprehensive portfolio of products for open, real-time capable OPC UA over TSN communication as well. With X20 PLCs, bus controllers, industrial PCs and a TSN machine switch, B&R enables fully standardized networks for modular, adaptive machines. The open standard reduces a multitude of protocols down to a single one, with a single interface exchanging standardized data between all the nodes in the network. Machinery and plants become substantially easier to develop and operate.

Reduced installation costs and more space

The new ACOPOSmotor devices facilitate the development of modular plants and machinery. They reduce installation costs and save cabinet space. The new motors cover a power range from 0.22 to 0.35 kW, and the smallest version measures just 60 x 90 mm. Despite their compact dimensions, they have a full-fledged integrated servo drive that enables control loops as fast as 50 µs.