Rotary tables for high-precision applications

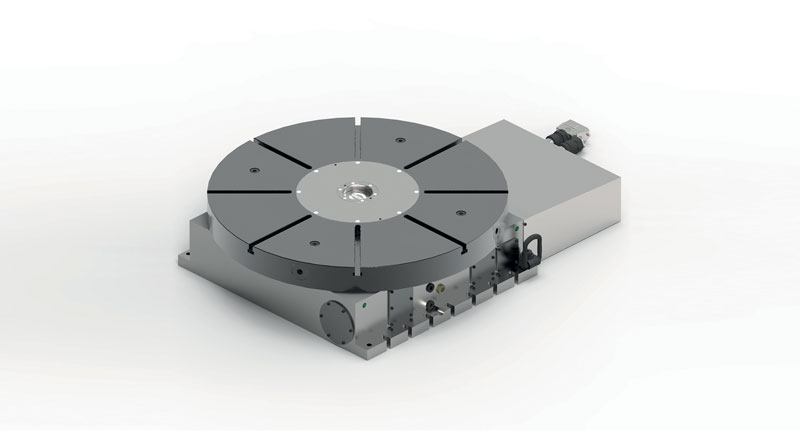

The new SAUTER RT Mill rotary table series with worm gear optimally meets the requirements for high-precision positioning of large masses, such as in machining centres for heavy-duty machining and boring mills.

The RT Mill series rotary tables from SAUTER FEINMECHANIK are designed for positioning workpieces with a diameter of 800 to 2,500 mm and a maximum weight of up to 40 t. The unique feature: within one size, various types of bearings are available for high payload or high-precision applications. The installation space remains identical. As a result, machine manufacturers are much more flexible when designing the rotary axis on the machine tool and can offer their customers several options for one machine.

Ten-channel oil distributor

All SAUTER rotary tables are standardized with a ten-channel oil distributor to actuate workpiece fixtures. This oil distribution feature enables workpieces with complicated clamping processes, such as truck engine blocks, to be machined efficiently. The worm gears installed are designed so that the rotary tables have a reserve for larger loads and higher mass moments of inertia.

SAUTER’s APC (Automatic Pallet Changer) also enables workpieces to be changed automatically: to go with each rotary table, the expert for rotating axes offers pallet clamping stations and pallet changing systems to DIN 55201. Non-productive times can thus be reduced to a minimum.