Screw Tightening Made Simple and Ergonomic

To automate assembly processes, OnRobot offers its OnRobot Screwdriver solution, an intelligent screwdriver that makes work easier and more ergonomic. Simple to program, it is able to improve the quality of operations and helps to limit waste; moreover, it can handle screws of different sizes

or different product lines.

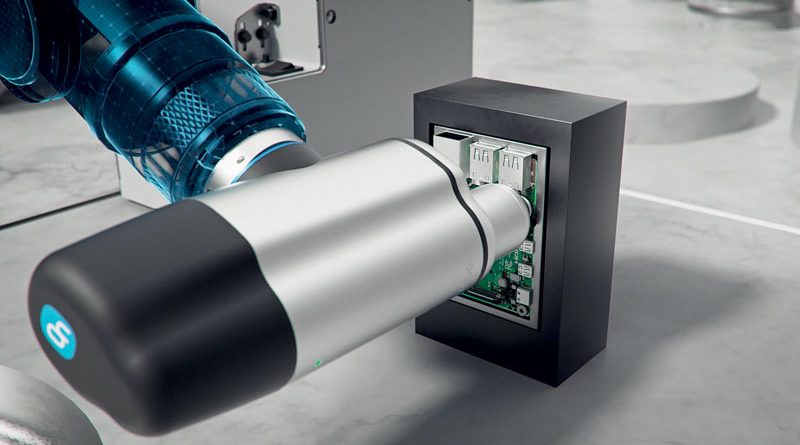

OnRobot, a company specialising in solutions for collaborative applications, presented OnRobot Screwdriver, an intelligent and complete screwdriver capable of automating a wide range of assembly processes in a simple, fast and flexible way. Manufacturing companies wishing to automate often repetitive, non-ergonomic and inconsistent manual screwdriving tasks now have an integrated and easy-to-program system at their disposal.

It is sufficient to enter the appropriate screw length and torque value in the integrated interface of the learning terminal present in each robot and OnRobot Screwdriver, with precise torque and axis control incorporated, independently calculates the speed and force required for accurate and consistent tightening.

Handling screws of various sizes

OnRobot Screwdriver is able to detect if the screw length is incorrect, helping to improve the overall quality of operations and reduce waste. Thanks to the “z” axis, the screws are retracted inside and automatically operated once the robot arm is in position, thus reducing additional movement and programming. Screws up to 35 mm in length are completely contained within the OnRobot Screwdriver when in motion, until the screwing process is safely started. The solution can handle screws of various sizes, from M1.6 to M6, up to 50 mm long and, thanks to the simple programming and the easily interchangeable bit system, can be replaced in a few minutes to handle screws of different sizes and lengths, or a different product line, minimizing downtime and improving productivity. The screwdriver’s robust and intuitive features include: integrated axis to ensure accuracy and ease of programming; precise torque control from 0.15 to 5 Nm; screw feeders available; ESD safe for electronic assemblies; OnRobot Quick Changer assembly.

The solution is compatible with OnRobot One System Solution, the unified mechanical and electrical interface between the main robotic arms and all OnRobot solutions. Users can thus benefit from easier integration and faster ROI.