Swiss innovation comes to Italy

BalTec, a Swiss multinational company specialising in the production of riveting machines, has recently opened a branch near Vicenza to serve as a reference point for Italian customers. The aim is to offer a more efficient assistance service and to let customers try out BalTec’s solutions, including the most recent ones, such as the line of 100% electric riveting and rolling machines.

BalTec, headquartered in Pfäffikon, Switzerland, was founded in 1983 by the Bräcker family business, which had already contributed to the spread of radial and tangential (now also called orbital) riveting and rolling techniques in the 1960s. “Our company,” Mattia Garziera, Sales Manager of BalTec Italia, explained, “specialises in cold forming techniques, which are used in various industrial sectors such as automotive, hardware, electromechanics, precision mechanics and the medical sector. The company currently has six subsidiaries, more than 70 employees and 40 business partners on all continents. In our technology centres and service points around the world, system builders and end users are supported in determining the optimal assembly procedure and guided through the integration on more or less complex machines and assembly lines”.

BalTec has finally arrived in Italy. The Swiss company, in keeping with its vocation for globalisation, has opened a branch in Italy to offer services, products and direct assistance to Italian customers. The office, strategically located in the heart of the north eastern part of the country, precisely in Schio, near Vicenza, acts as a reference point on the national territory even for technical advice, thanks to its capable and competent staff able to propose customised solutions. “We are convinced,” Mattia Garziera continued, “that the high-quality level of BalTec products and customer satisfaction can only be guaranteed with a strong local presence”. The technology centre allows Italian customers to discover the possibilities in the field of connectors, to carry out on-site tests before investing, and to start series production.

BalTec Italia technicians offer specific assistance even on older machines which have been installed in factories in Italy for more than 30 years. Repair work complies with the construction standards of the Swiss parent company, using original and guaranteed spare parts. Like all BalTec branches around the world, the Italian branch also offers all-round support by representing other companies whose production can in some way complete the product range. BalTec Italia is the distributor of Janome Industrial products, a Japanese company active since 1921 on the international markets for the production of servo-presses and robots and the EMG manual and pneumatic presses produced in France.

A solution for every application

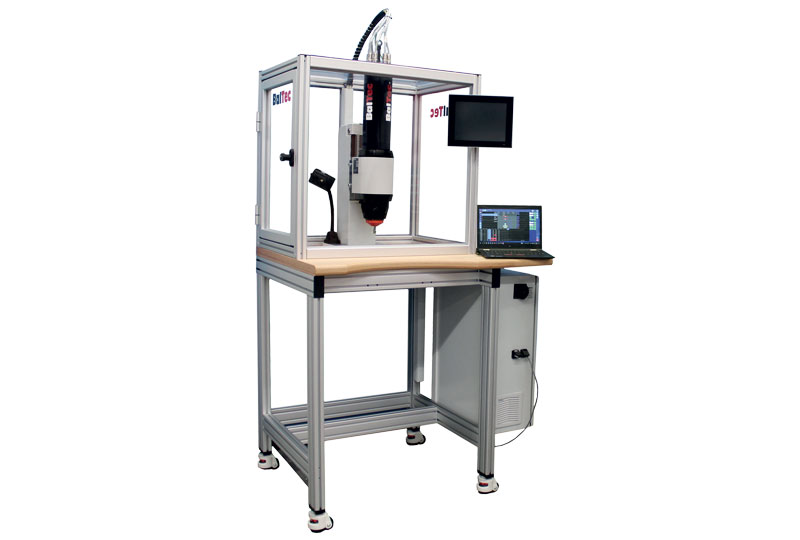

“BalTec has the perfect machine for every application thanks to its flexible and scalable configurations,” Mattia Garziera continued, “we offer a wide range of solutions and develop processes for connections requiring high quality, which we can achieve thanks to the experience we accrued over the years. The cold forming products we offer range from radial riveting and orbital riveting, through rolling to pressing”. The machines developed by BalTec can be for manual bench use: these are complete workstations with cast iron column and table, bimanual control button, safety relay, height adjustment and clamping. Column machines designed for machining tall or long workpieces are, on the other hand, equipped with an adjustable work table, cast iron column and table, bimanual start button and safety relay. Finally, the machines with indexing rotary table are equipped with column and column plate, electric indexing rotary table, protection structure, two-hand push button with safety relay or pedal control, pneumatic ejection of the riveted parts and the double riveting machines for performing a simultaneous riveting process. “As you can well understand,” Mattia Garziera stated, “ there are an infinite number of variables which must be studied one by one with our customers in order to guarantee the best possible result for their production line”.

Electrical innovations

“Like any company,” Mattia Garziera said, “BalTec looks to the future and the development its technology may have, and we follow a path of continuous improvement and innovation which we pursue side by side with our usual partners”. In recent years, the company has developed a line of machines called ELECTRIC, 100% electric and controlled by HPPi software for process monitoring and remote assistance. “This new generation of machines,” Mattia Garziera continued, “can guarantee faster process times, precise and fast production as well as clear energy savings”. The operation is based on a linear stroke movement superimposed on a rotary movement and is covered by an international patent. The advantage of these machines is that they can produce permanent mechanical connections in a radial, orbital or rolling process with high speed and precision. The different forming technologies can all be performed by one machine, thereby offering the customer maximum operational and production flexibility. The ELECTRIC series, as well as its predecessors in certain configurations, are designed for interconnection with company information systems via OPC/UA communication protocols, and can therefore benefit from funding provided by the Transition 4.0 plan.