The handling of the future

Precision in handling is very important, especially when it comes to assembly operations. A small error, in fact, can compromise the final product. That is why components like pneumatic grippers play a fundamental role. Camozzi Automation offers a wide range of grippers for different handling requirements, always with the aim of ensuring precision and speed. Fabio Bottarelli, Business Development Manager Handling & Robotics at Camozzi Automation, told us all about it.

For more than 50 years, Camozzi has specialised in systems and technologies for industrial automation. Could you provide us with a brief overview of the company and its values?

With a widespread presence in over 70 countries all over the world, Camozzi Automation is a specialist in the design and manufacture of components, systems and technologies for motion control and fluid control in the Industrial Automation, Life science and Transportation sectors. The Camozzi Automation offering increasingly includes the development of IIoT products and solutions. We create added value for our customers by combining leading mechanical and digital technologies to ensure reliability, flexibility and increased production efficiency. Our task is to enable customers to digitise their production processes and to implement real cyber-physical systems to constantly improve process performance and data chain management.

Camozzi’s mission is to accompany its customers in the development of innovative, efficient and high added value solutions which can positively impact the future of the environment and of people. We do this through our components, which are designed to enable our partners to best meet the technological challenges of the future.

Handling is a very large sector requiring very precise and versatile components capable of ensuring maximum plant productivity. How do Camozzi components fit into this context? What added value can they bring?

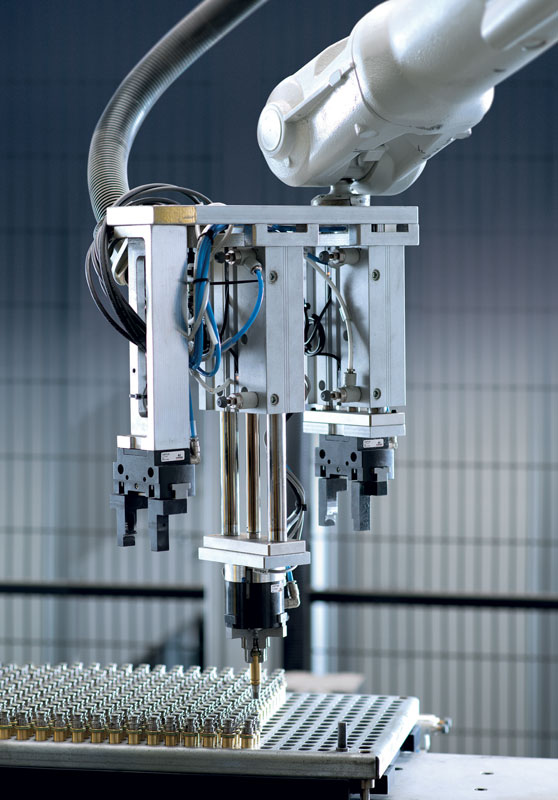

I am thinking above all about the pneumatic grippers. When we talk about handling at Camozzi we consider three different product families: grippers, actuators (such as, rotary and guided actuators) and vacuum technology. Thanks to these three different solutions, we are thus able to create end-of-arm tooling ranging from very simple ones, obtained using a gripper or a suction pad, to complex ones in which the three technologies merge together to ensure the handling of objects having complex dimensions and shapes. Entering into the details of pneumatic grippers, Camozzi’s offer is complete and varied; classic parallel, radial, angular and concentric grippers with three jaws can be found. Parallel grippers are the most common and are characterised by a linear and parallel movement of the jaws; in radial grippers, the jaws move by rotating with openings that are usually 90° per jaw and therefore a total of 180°; angular grippers also move by rotating, but the opening is usually limited to 15° per jaw and therefore a total opening of 30°; finally, three-jaw grippers have a linear and concentric movement of the jaws and guarantee a better grip with circular components. Alongside these, there are also specific grippers for the plastic moulding sector: these, commonly called sprue grippers, are dedicated to use in the end-of-arm tooling which remove plastic injection moulded parts from the moulds; a typical feature is that they have non-self-centering fingers, so that they can adapt in the best possible way to gripping the sprue.

Alongside these types, which we could define as standard, there are also special grippers. These are based on the specific requirements of our customers, with the aim of finding the solution which best covers the requirements of the application. Customisation can be of various kinds: development of special fingers based on the dimensions and shape of the object to be handled; insertion of special functions not envisaged in standard grippers (such as, adjustment of the opening and/or closing stroke); development from scratch of grippers based on the customer’s design or co-design.

In any case, all Camozzi Automation grippers have common features, for example they are developed and manufactured in Italy. In addition to the variants specific to each series, ATEX and high temperature versions are available, and there is the possibility of using lubricants suitable for use in the food industry instead of standard lubricants. Materials and surface treatments are chosen to optimise corrosion and wear resistance performance, thereby allowing high levels of reliability to be achieved. All grippers are copper, silicone and PTFE free, ensuring applicability in electronics assembly, painting and explosion hazard areas respectively. Last but not least, all grippers are equipped with a cover against the penetration of dirt and impurities.

Every application has its solution, even the less ‘conventional’ ones. Could you provide us with some examples of this type of application in the assembly world on which Camozzi has worked?

What drives product development at Camozzi Automation is the ability to solve the needs of specific sectors and/or applications. Within the assembly sector there are some requirements which are more in demand than others. The grippers must weigh as little as possible while maintaining strength and the ability to withstand the dynamic loads generated by the high acceleration of the systems which move them; at the same time, they must guarantee rpositioning repeatability throughout their life, able to arrive around 0,02 mm 0.02 mm, together with high opening and closing frequency and speed, therefore they must be able to save fractions of a second in this operation. In many situations, it is important to have systems that keep the gripper in a precise position (open or closed) to ensure that, in the event of a lack of air or pressure drop, the item is held. Once the grippers have reached the end of their service life, they must be easy and, above all, precise to replace: this means that they must guarantee replacement without the system having to be readjusted or modified. Another important feature is that they must not contain copper: this is an essential requirement when handling electronic components, because copper, if accidentally present on electronic boards for example, could cause malfunctions.

With this in mind, I would like to mention two of the latest grippers which have just been developed with the needs of the assembly sector in mind. The first is the Series CGSP parallel gripper, which is available in four sizes (20, 25, 32 and 40) and features a T-shaped sliding guide which is highly resistant to external loads and a high-performance lever transmission system. These two features make the Series CGSP a gripper capable of providing a high strength-to-size ratio; despite its very small size, it can withstand high external stress and exert high clamping forces. The applications where these performances are most used are those characterised by high acceleration and speed of movement of the motion system, such as insertion and machine, tending typical of the electronic components assembly sector, the medical sector or the cosmetics industry. Another typical application is end-of-arm-tooling in the plastic injection moulding sector, where the objects to be handled are typically light but the accelerations of the pickers unloading the part from the mould are very high. This gripper also lends itself well to being combined with tripod systems.

The second series is the CGSY: these are radial grippers, which typically have a very wide jaw opening, in this case 180°. This feature is very useful in applications where it is not the gripper which moves towards the item, but rather the latter moves towards the gripper: this is because, by opening up to 180°, it frees up space and allows the item to approach without having to make further movements to the gripper. An example is the assembly machine tending with rotary tables or PET bottle blowing machines; in this application, it is also necessary that the grippers mounted on the moving axis open and close in unison, so as to reduce the cycle time as much as possible. The Series CGSY is manufactured by calibrating the bore and supply channels so that all grippers have identical behaviour in terms of opening and closing speed.

The market is evolving rapidly, including the assembly and robotics market, what are the new development trends which Camozzi is focusing on to keep up with the times?

The trend is towards increasingly intelligent products, enabling manufacturers of assembly machines and robotics to adopt smart manufacturing paradigms.

For example, the insertion of sensors into components allows decisions to be made on the work site in order to be faster without further burdening the overall infrastructure (so-called ‘edge’ processing). Depending on the product, specific switches and vision systems can be integrated. In the case of pneumatic grippers, proximity sensors, tactile sensors, force/torque sensors and position/speed sensors (such as, accelerometers) or other systems can be used to detect the gripping of the item, its weight and any dimensional defects.

The more sophisticated the electronics, the more self-learning or artificial intelligence systems can be adopted, which, once trained, do not need to be reconfigured. Besides, these technologies allow predictive maintenance checks, or help configure and reconfigure products quickly, cutting down on setups or format changes.