The role of vision in robotic fluid dispensing

Key to streamlining robotic fluid dispensing, vision-guided systems allow precise deposit placement, permitting these robotic systems to deliver faster production cycles and remove the guesswork from the dispensing process, which minimizes programming time and reduces overall operational costs. Nordson EFD tells us about it.

There are many factors that manufacturers consider when deciding which equipment to invest in for fluid dispensing operations. Critical is the need to deposit very small and precise amounts of fluid, such as adhesives and silicones, to assemblies like tiny micro-electronics and other minuscule parts. These tiny amounts of fluid must be dispensed reliably and accurately in dosage and placement. The precise positioning and quantity of these fluids deposited on the substrate is vital to those products’ assembly, function, quality, appearance and viability. In addition to maintaining precision dispensing standards, the fluid dispensing method must also meet requirements for throughput volume, worker safety and cost efficiency.

Robotic fluid and vision-guided dispensing

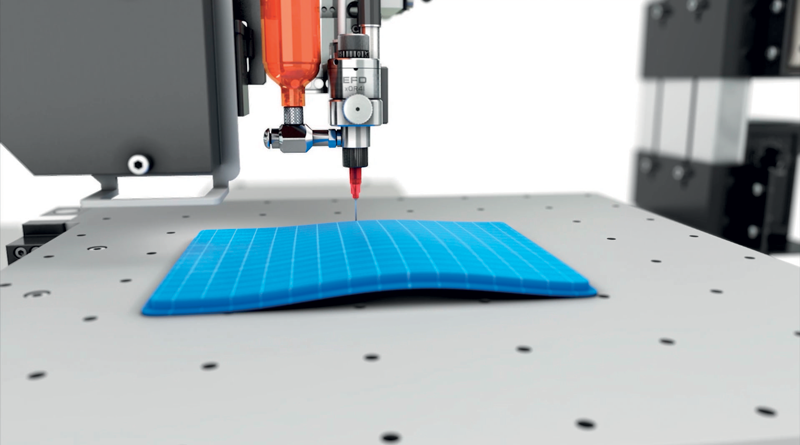

Many fluid dispensing applications use robots to achieve these objectives. Robots provide process-critical flexible automation that also maintains consistent fluid deposition with extreme accuracy, time after time. This precision repeatability optimizes fluid usage, reducing waste and production costs. Robot software adjusts the positioning of dispensed material automatically to accommodate curves or complex contours, or slight errors in workpiece positioning in the nest or fixture, which would otherwise prove difficult to achieve with non-robotic methods. Controlling fluid deposition with visional-capable substrate and pattern recognition, ensures the deposit is in the correct location up to positional tolerances of ±3 µm. It can precisely manage different materials being dispensed, such as adhesives, greases, epoxies, silicones and sealants. Robotic dispensing software also permits the importing of AutoCAD DXF files, so the manufacturer can program fluid dispensing patterns in their preferred CAD software, then import the DXF file from their software seamlessly into the dispensing automation platform. Robotic fluid dispensing is essential for applications that require extremely accurate and repeatable fluid deposit placement, complex dispensing patterns, and/or high-volume throughput. Central to this performance is the robot’s vision-guidance system. Vision gives flexibility to the robot by allowing precise deposit placement. Vision has been used in fluid dispensing applications for over twenty years, and is becoming more prominent as robots, and their control software, get smarter. It permits these robotic fluid dispensing systems to deliver faster production cycles, and removes the guesswork from the dispensing process, which minimizes programming time and reduces overall operational costs.

Point-to-Point Teach Method

The most fundamental form of dispensing automation programming is done with a teaching pendant device, and eyeballing the location of the dispensing tip on the substrate being dispensed onto. Essentially, the point-to-point teach method is executed manually. The operator moves the tip over the substrate location where dispensing is to be targeted. Once the substrate location and coordinates of the X-Y-Z axes has been determined, they are saved in the control software. This process is repeated for all substrate locations where deposition is targeted. The robot will move to these precise locations every time, and dispense fluid as dictated by the fluid dispensing software. A high volume of dispense patterns can be programmed with the teaching pendent, point-to-point method. But the amount of patterns that are being dispensed is a criterion for limit, if simply because of the amount of time it would take to program. Also, with more complicated dispensing, the need for an offsetting capability increases. By this is meant the ability look at a location on the substrate before the dispensing is done, and to offset the program if there are any changes to the substrate. This is where vision systems would be better suited for the application.

Simple-vision and CCD-equipped vision

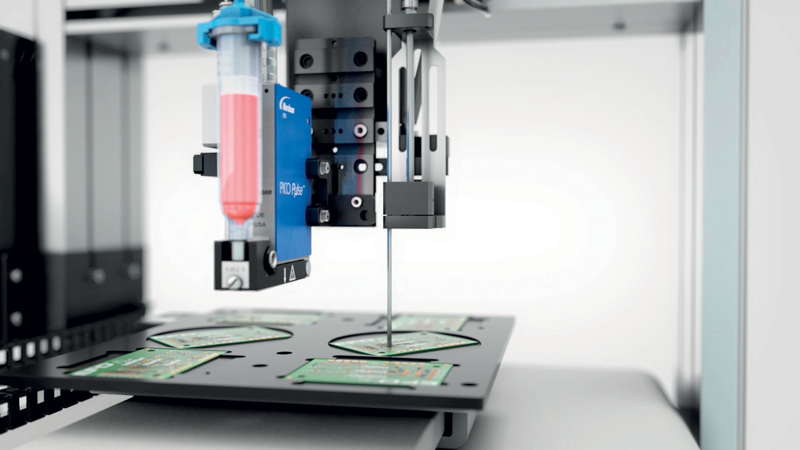

When we talk about vision systems for robotic fluid dispensing, these can vary from simple pencil cameras to sophisticated CCD-equipped vision. The defining difference is in the resolution – how many pixels in the camera’s sensor – and the camera’s shutter speed ability. For most robotic dispensing applications, the simple-vision pencil camera system is adequate. But if very fast, high-resolution photos of substrate parts are needed, a CCD camera would be required. Both cameras function by taking a picture of a part on the substrate, and then applying any necessary offsets by adjusting the dispensing program to match the location and shape of the path with the location and shape of the part. More specifically, the camera verifies the location of a part by identifying a distinguishing edge of the part that can be referenced. That reference point will allow the dispensing software to offset fluid dispensing if that point changes location – such as if the substrate registration is slightly displaced when positioned in the robot – and allows it to apply that offset change to where the dispensing is now to be placed on the substrate. Pencil cameras and CCD cameras both convert analogue camera image pixels into digital values for extremely precise image management. Some relatively inexpensive pencil camera systems, combined with specialized dispensing software, such as those offered by Nordson EFD on its 3-Axis EV Series Automated Fluid Dispensing Robot, allow even first-time users to program complex dispense patterns and arrays with high repeatability up to ±8 µm. Comparatively, CCD cameras capture even higher-definition images, such as that offered by Nordson EFD on its 3-Axis PRO Series Automated Fluid Dispensing Robot, which captures detailed component part images, where shadow enhancement allows vision identification and processing of poor, faint marks, with minimal time interruptions to the dispensing cycle. When paired with intuitive dispensing software and a closed-loop motion control system, the CCD camera enables the PRO Series to achieve best-in-class repeatability of ±3 µm. The PRO Series also permits a laser height-sensing capability to be added on. Laser height-sensing allows it to map the topography of the substrate and pass those measurements back to the robot so that it can automatically offset the Z-axis values and maintain the correct dispense gap over the substrate. The process occurs in real time for every part that runs using this feature – ensuring high-quality dispense outcomes, even on warped or twisted substrates. These fully integrated, smart vision CCD cameras for robotic fluid dispensing provide true three-dimensional motion control. The robots then have three types of feedback when the CCD, tip-detect device and laser-height sensor are installed – optical, contact and non-contact laser-height sensing – which allows for easy programming of dots, lines, circles, arcs, compound arcs and complex patterns. The tip-detect device changes the offsets to the program if a tip changes on the syringe or valve.

Advanced vision-guided dispense software

Enabling this ultra-precise, high-speed simple-vision and CCD-equipped vision capability found in these latest-generation robotic fluid-dispensing systems is advanced vision-guided software. Such software programs, like DispenseMotion from Nordson EFD, enable the full capabilities of vision-guided fluid dispensing to be realized from these robotic systems. One of the most distinguishing aspects of this software’s integrated functionality is its precision in the control and management of the critical offsetting capability, whereby it compares the current workpiece location to a reference location that is stored as an image file within the program. When the robot detects a difference in the X and Y positions and/or the angle of rotation of the workpiece, it is this software that automatically adjusts the dispensing path to correct the difference. The offsetting function is constantly receiving process data to ensure that the dispensing process is executed with precise control. Simplicity and ease-of-use always being a vital aspect with system operators – despite this software’s advanced dispensing capabilities, its intuitive interface simplifies set up, and facilitates programming with an on-screen preview of the dispensing path. Tasks of importing and converting DXF files are equally simple. Recently, a Robot Initial Setup Wizard was added to DispenseMotion making the dispensing robots even easier to use by visually steering operators through each step of the setup process, including the calibration and setting of offsets in the simplest way possible. These latest-generation fluid dispensing robot systems – exemplified in Nordson EFD’s GV, RV, EV and PRO Series models for 3-axes and 4-axes applications – with their advanced software and vision-guided capability, bring repeatability and precision to automated dispensing systems and assembly operations. Ideal for dots, lines, potting, damming, filling, underfilling, encapsulation, sealing, coating and jetting – syringe-based and valve-based – they offer sophisticated fluid dispensing capabilities, more accurate placement, and greater consistency, while remaining simple and intuitive to program. This integration of robots with advanced dispensing software and vision, has considerable benefits for manufacturers, including greater part production capacity, reduced manufacturing time, consistent accuracy over rough and uneven surfaces, improved product quality, and the ability to take on more complex projects that require very precise dispensing and fluid placement.