There Is More Beyond the Machine

Advanced monitoring systems, augmented and virtual reality. Beyond the actual machine building, assembly machines manufacturers will be increasingly focusing on some value added services. Alongside a special line for assembling a small electrical device, equipped with all the necessary control systems to test the compliance of every single piece, at SPS Italia Cosberg showed the company’s vision for the near future.

by Leonardo Albino

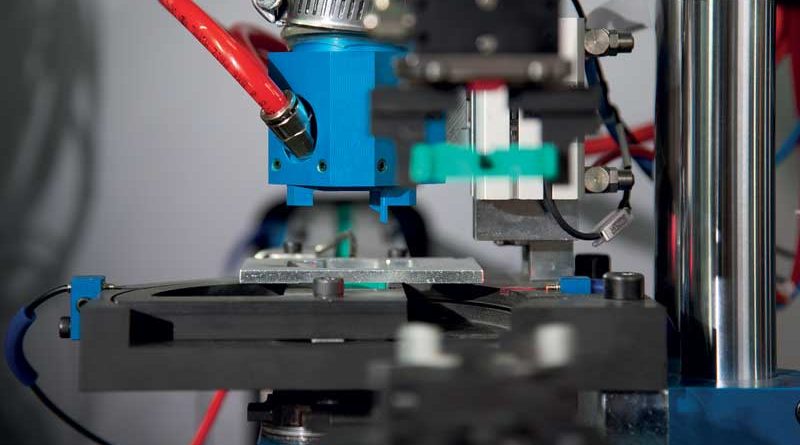

The participation of Cosberg in SPS Italia followed quite a precise pattern: looking towards the virtual world definitely starting from the actual, concrete, tangible part of a project. In other words, the machine. The special assembly line on display at the fair was designed and built for assembling a small electrical device. In addition to mounting two product variants, the machine can perform all the necessary controls to test the compliance of every single piece. In detail, the line is made of a machine that assembles several components, including springs, sliders and contacts. The slides subassembly is pre-mounted on a rotary table – connected to the main line – and placed on the machine processing areas by means of a patented pick & place electro-mechanical arm. The latter is moved by an easily reachable cam, thus making possible not only to set different picking and release parameters, but also to re-set the motion through further cams manufactured according to customers’ needs. To sum up, easier setup, high precision and reliability, greatly reduced maintenance. Last but not least, significant energy savings.

Thorough control of the process

Manifold controls are carried out. By means of advanced vision systems, the compliance of every component to the product code is checked. This is a key operation, as the line manages to produce several variants of the device. Talking about vision, a camera detects the presence and correct positioning of all the components inside the device, performing controls on 19 spots.

The specific controls on the slider spring are carried out by a device equipped with an electric cylinder using a load cell. The presence of the screw holes and the opening of springs are checked, as well as the dielectric strength of the contacts according to specific parameters set by the customer. Finally, continuity, resistance and insulation are detected through dedicated equipment. The cycle ends by marking every single piece, in order to guarantee its traceability. The PC on board the machine is equipped with a production monitoring system, making it possible to calculate statistics as well as to analyze possible downtimes.

Clear ideas for the (near) future: advanced monitoring and virtual reality

“Thanks to the partnership with Miraitek (a spinoff from Politecnico di Milano specializing in production machines data analysis, ed) we are currently developing a cloud-based monitoring system – says Michele Viscardi, Business Development Director at Cosberg – that may not imply the need for additional hardware on board the machine. The system is also supposed to allow the professionals involved to oversee the machine status, thus accessing information also via wearable devices”.

Another important support to customers may come from virtual reality, a technology that is getting closer and closer to manufacturing. Cosberg showed the visitors the opportunities of the virtual representations of both the machine and its operation. In fact, a device made it possible to interact with the physical parts of a machine – from doors to buttons, up to human-machine interfaces – in order to understand its operation, including the action of removing the screws to dismantle the mechanical parts. “We consider virtual reality as an enabling technology – adds Mr Viscardi – to be used for training purposes for either our own operators or, above all, customers. The aim is not to stop production when a training session is required”.

How the service to customers may change

Another service that might become a standard in the future of manufacturing deals with the use of augmented reality to provide remote assistance as for the mechanical part of a machine. Similarly to what currently happens for the software. “If we think – continues Michele Viscardi – that most of our machines are installed quite far away from Italy, providing the customers with augmented reality devices would allow us to promptly intervene in case of any trouble. Our operators may guide customers remotely or rather show additional information aimed at guiding assistance activities on the machine”. Whether production data monitoring or technologies like virtual and augmented reality are involved, we are talking about after sales services that may support customers’ everyday work. The underlying idea refers to the often mentioned “product as a service”, which of course implies a necessary change in terms of mentality and culture. “We are quite confident and we expect a great feedback from the market and a boost to our relationship with customers”, says in the end Cosberg’s Business Development Director.