Working in Synergy for High-Speed Assembly

With the collaboration of K.L.A.IN.robotics, ADAT created a system for the high-speed assembly of faucets. The machine can reach a flow of 40 pieces/min, even different from each other, thus ensuring flexibility and zeroing of set-up times.

di Giordano Bracco

The consultancy and technical service of K.L.A.IN.robotics are the driving force to create solid and lasting partnerships. Proof of this, it is the historic collaboration established with ADAT, a company specializing in the design and implementation of complete and integrated industrial automation solutions. Thanks to the support of K.L.A.IN.robotics, ADAT has created a system for the high-speed assembly of a faucet, developed for a Sicilian company that manufactures irrigation components. The machine is currently in production with a flow capable to reach 40 pieces / min, changing the format in a few seconds.

Since 1987, ADAT proposes itself as a partner for the industry, supplying automation systems tailored to every need. The company carries out all the project phases internally, starting from the problem analysis strategy, up to the delivery of the “turnkey” system. The activity of ADAT is based on the use of systems using robots or newly developed systems with dedicated mechanics, the management of axis controls regardless of PC or PLC, the use of the most varied types of sensors, as well as putting all this in communication with database for the acquisition of processing data rather than for the communication of results. Here is the role of K.L.A.IN.robotics, which is ready to offer its consolidated experience and offer the best solution in terms of efficiency and costs by applying cutting-edge quality components.

From disarranged components to a precise assembly

The machine is the result of the encounter of ADAT with a Sicilian company producing irrigation components and, specifically, plastic faucets. The first step in the project was to study the production system to create a machine that can flexibly cover the entire production.

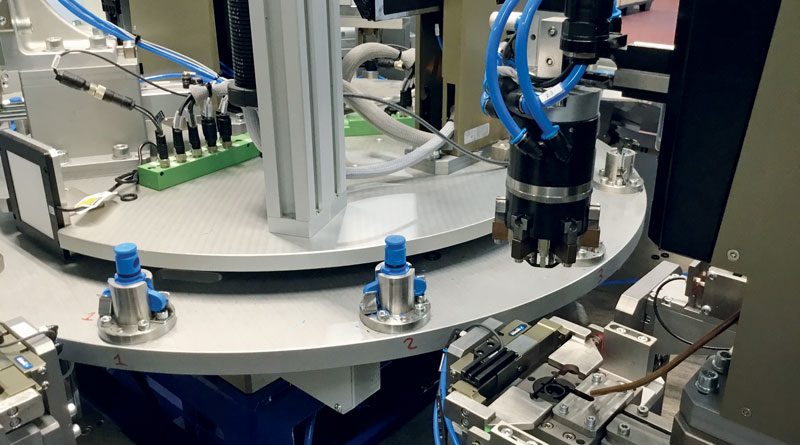

The goal of the system was to process the high-speed assembly of the faucet, ensuring flexibility in the management of about one hundred different models and the zeroing of set-up time. The operation consists of feeding the basic components starting from the bulk, the valves, the bodies (about 100 different shapes and sizes) and the O-rings that must be mounted on the valve after being accurately lubricated. In addition to assembly, the system checks that all the processes take place correctly, managing the correct assembly of the O-Rings and the valve itself on the body via cameras. The challenge was successfully met thanks to the collaboration with the customer, optimizing the process through the use of different technologies provided by the network of ADAT partners, including K.L.A.IN.robotics.

Two cameras monitor the work of the robot

If feeding pieces with identical shape and size is not a problem, it is a whole different story when it comes to handling very different pieces, maintaining high positioning precision and with no need for mechanical format changes. ADAT needed a flexible vision guided robotic system that can be completely and easily programmed by the operator, so that the pieces fed in bulk were collected by a camera-driven robot.

The vision guided robotic system was completely developed by ADAT.

However, the know-how of KLAIN.robotics also came into play here, as they provided ADAT with a DENSO robot, which was then implemented with a flexible vision guided robotic system. This made it possible to manage hundreds of body models, in addition to guaranteeing future compatibility, given the extremely easy system programming in case of new pieces. A camera checks the correct assembly of the O-Rings, which cannot be verified after assembly, thus solving any non-compliance at the source. Moreover, a second camera analyzes the correct insertion of the valve on the body, avoiding the presence on the market of damaged or not conforming pieces.