Future-proof precision power analyzer

High accuracy, stability, noise immunity and plug-in modular flexibility: these are the features of the next generation of precision power analyzer by Yokogawa Test & Measurement, ideal for energy-efficient systems

by Claudia Dagrada

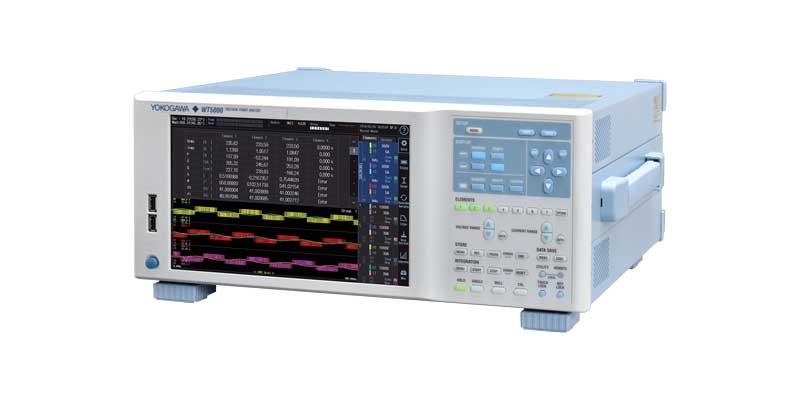

At the end of September, Yokogawa Test & Measurement launched the new Yokogawa WT5000, the first of a new generation of precision power analyzer. During a specially organized event in Milan, Anoop Gangadharan, Product Marketing Manager – Power Measurement Solutions in Yokogawa Europe, introduced the solution. As he told to the audience, the WT5000 offers a measurement accuracy of ± 0.03% combined with stability, noise immunity and plug-in modular flexibility to meet the measurement needs of today’s developers of energy-efficient systems.

A product which satisfies the challenges of tomorrow

In industry sectors like electric vehicles, renewable energy and energy efficient technologies, the need for reliability in testing to enhance safety, efficiency and performance has never been greater. Changing application needs on one hand, and evolving international standards on the other hand, call for custom measurements and consistent accuracy. In the WT5000 Precision Power Analyzer, engineers have a versatile platform that delivers reliable measurements in many sectors, from aerospace to automotive, from medical to the robotics, from appliance and lighting to drives and much more.

The main technical features: accuracy and high plug-in modular flexibility

The WT5000 achieves the world’s highest measuring accuracy: ±0.03% of total at 50/60 Hz. As a result, it has become possible to evaluate the power consumption, loss, and efficiency of electrical and electronic devices. In particular, its wide dynamic current range is indispensable for tests on energy-saving designs. One of the essential elements for determining the performance of a power measuring instrument is the A/D converter that performs analogue-to-digital conversion. In order to obtain such a high measurement accuracy, the WT5000 uses an 18-bit converter with a sampling frequency of maximum 10 MS/s. As a result, it becomes possible to accurately capture waveforms from the latest high-speed inverter devices. It is very effective for stable measurement results. While the WT5000 has the same dimensions as existing models in Yokogawa’s WT series, it incorporates up to seven input channels, allowing it to support applications that previously could only have been measured by synchronising several separate instruments. As a result, it offers considerable savings in installation space, communications overheads and cost-effectiveness. Further benefits result from the use of plug-in modular input elements, which can be swapped directly by the user.

Same application examples

The 30 A and 5 A elements, for example, can be switched for applications involving electric vehicles or fuel-cell vehicles, where developers are increasingly required to evaluate a number of different motors. Using the WT5000 equipped with the /MTR1 and /MTR2 options, it is possible to evaluate up to four motors simultaneously with one unit. Since these options allow the input of four channels, flexible measurement of the A, B, C and Z phases of each motor can be carried out. With a 7 elements input capability, multi-system measurement is increased in harmonic measurements on 3-phase systems, for example. The WT5000 can carry out two harmonic measurement functions simultaneously, each at up the 500th order and up to 300 kHz fundamental waveform. This makes it possible to measure the carrier frequency component from the rotational speed of the motor in the inverter drive, and also to check the influence of the carrier frequency on the motor drive. Moreover, an increasing number of applications require the evaluation of larger-current devices, typical examples being electric vehicles and large-scale solar installations. In these cases, external current sensors are often used. An external current sensor input function is fitted as standard in the input element of both the 30 A and 5 A input elements of the WT5000. For much higher currents (up to 2,000 A RMS) dedicated high-current sensors are available. Yokogawa AC/DC current sensor CT series is current output type in order to prevent noise influence.