Accurate Inspection and Controls

The case histories of this article profile Turck Banner as an ideal partner in activities such as inspection and control: let’s see the use of its Smart Cameras Serie VE, together with the software Vision Manager, in the automotive and consumer goods sectors

by Vittoria Ascari

The Smart Cameras Serie VE from Turck Banner with the Vision Manager Software allow to solve a wide range of vision applications, such as item detection, part positioning, feature measurement and flaw analysis.

Smart cameras are available in 5MP (2592 × 2048 pixels), 2MP (1600 x 1200 pixels), 1.3MP (1280 x 1024 pixels), and WVGA (752 x 480 pixels) models, all with the same powerful inspection capabilities. Runtime editing capability reduces costly downtime and the software emulator allows for offline building and troubleshooting of applications.

Factory communications are guaranteed by EtherNet/IP, Modbus/TCP, PROFINET, and RS-232 connections for integration on the manufacturing floor. VE series are equipped with six optically isolated I/O and an external light connector type “C” on the sensor. The two-line, eight-character onboard display provides inspection information and focus number and makes it easy to update sensor settings, facilitating fast product changeover. A robust metal housing with optional lens covers permits to achieve IEC IP67 rating for use in harsh environments with heat, vibration, or moisture. Indicator lights allowed an easy viewing of camera status.

VE vision systems are successfully applied in harsh production environments where accurate inspection and controls are constantly needed.

Inspection of each cars’ door panel for the presence of adhesive

During the assembly of a vehicle door, a track of heavy-duty adhesive is applied along the perimeter of the outer panel. The outer and inner panels are then joined together by an industrial press. If an insufficient amount of adhesive is applied in any area, the panels will not adhere correctly. If an excessive amount of adhesive is applied, it may burst through the seams, requiring cleanup and potentially coming into contact with adjacent components.

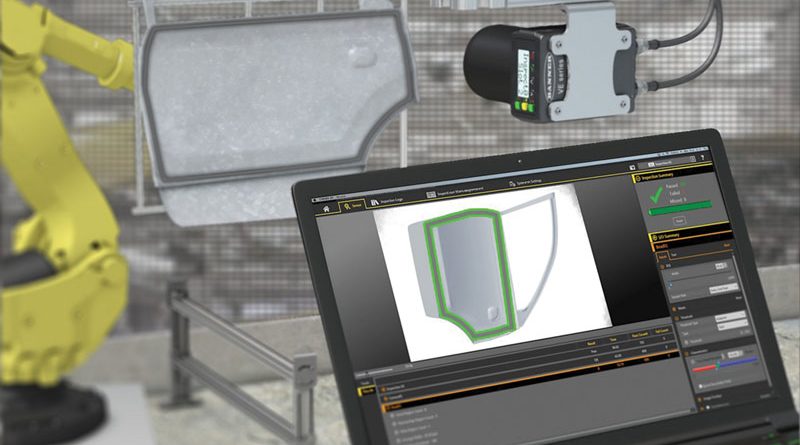

A VE Series Smart Camera, configured to use the bead tool, inspects each door panel for the presence and consistency of adhesive. The camera has a wide field of view and a 2 MP imager capable of detecting even slight inconsistencies in the amount of adhesive applied.

Viewing each inspection and diagnosing application issue

Turck Banner’s Vision Manager Software simplifies setup and management. This free image processing software provides the operator with powerful inspection tools, easy access to real-time inspection data and an intuitive user interface with a graphical display of the inspection area. The software emulator enables offline development and troubleshooting of applications. The graphical user interface allows operators to view each inspection, identifying and diagnosing application issues. Tracks of adhesive passing inspection will appear green, Tracks with excess adhesive will appear blue, while tracks with an insufficient amount will appear red. Runtime editing allows the operator to update an inspection while the sensor is in operation, reducing the downtime and hassle associated with stopping and restarting inspections.

The camera supports Ethernet/IP, Modbus TCP and PROFINET industrial protocols to facilitate integration with existing factory equipment. It is protected by a metal housing, and is deployed with an optional lens cover with a borosilicate glass window for further protection from area hazards.

Consumer goods: inspections of the logo of tubes of toothpaste

VE series are the ideal solution even in consumer goods packaging. Here we talk in particular about tubes of toothpaste. During packaging, they are placed into paperboard boxes for shelf display and sale. A logo on the packaging indicates the specific type of toothpaste inside the box. Frequent product changeover, printing mistakes, human error and other factors can result in packaging errors. A Turck Banner VE Series Smart Camera inspects the product logo on each box before the tube of toothpaste is inserted. As a box enters the inspection area, it is detected by a sensor on the line and an output is sent to the trigger input on the camera, which captures an image of the region of interest (ROI). A red LED ring light powered by the camera enhances the contrast between the product logo and the surrounding packaging.

The camera is configured and inspection parameters set using Vision Manager Software. A graphical user interface simplifies setup and management, and provides users with real time information from each inspection.

The software emulator allows the operator to develop inspections offline and send them to the camera when the application is ready.

Updating an inspection while the camera is in operation

Configured to use the Match tool, the camera inspects each box, verifying that the logo matches the reference pattern and meets the criteria established during setup.

If inspection parameters need to be altered, runtime editing makes it possible to update an inspection while the camera is in operation without stopping and restarting inspections.

Boxes failing inspection are rejected from the line before the toothpaste tube is inserted. An optically isolated output on the camera triggers a CL50 Column Light to shine red for each failed inspection and green for all passing inspections, providing high visibility status indication from the packaging line.

VE Series Smart Cameras can store up to 999 inspections, ideal for applications with frequent product changeovers. Operators can change the inspection using the PC interface, or on the camera using the four on-board buttons and the two-line, eight-character LCD display.