Measuring System in Rotary Motion Control

A French car maker asked Mahr to develop a customer-specific system for measuring the roughness of a key engine component. The result is a rotary indexer created together with a Nexen sales and marketing partner

by Vittoria Ascari

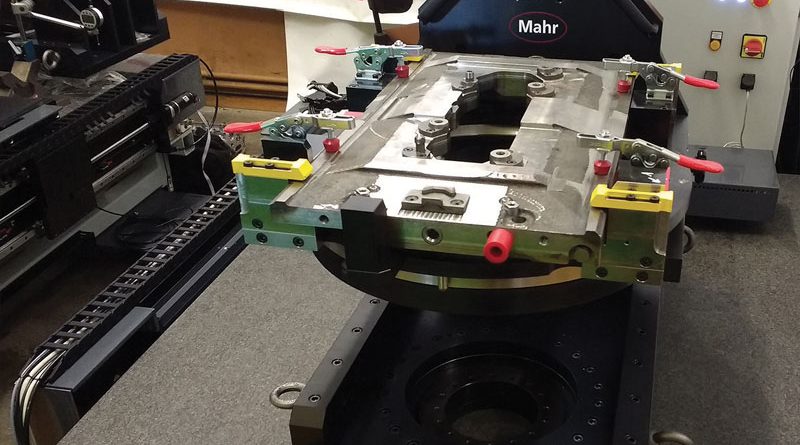

Compact ring drive systems from Nexen are used in industrial rotary applications where high positional accuracy and dynamic performance are required. The custom rotary indexer CRD350 was developed jointly with the metrology specialist Mahr for a French automotive manufacturer.

Nexen Group, with its headquarters in United States, is among the worldwide leaders in power transmission, linear and rotary motion, and tension control components. Nexen’s customers span every industry, from multi-national corporations to small businesses, and range from design engineers to plant maintenance. It has more 40 sales offices and more than 1,500 distributor outlets worldwide.

On the other side, Mahr is a German global manufacturer of production measuring technology and is active all over the world. From the simple caliper gauge to precision optical measuring systems, it is a key supplier in a wide range of industries including the automotive industry, medical technology, aviation, optics and renewable energies. In many sectors where precision is an essential production factor, equipment from Mahr is at work, delivering high accuracy in measuring dimensions, contours and surfaces with the smallest possible tolerances.

A system for measuring the roughness of a component

As an application specialist in production measuring technology, Mahr provides solutions to its customers’ metrological tasks, and serves as a consulting partner in all quality-critical questions.

Mahr received the order to develop a customer-specific system for measuring the roughness of a key engine component for the French car maker. To complete the order, Mahr entered into partnership with Unicum Transmission de Puissance, Nexen’s sales and marketing partner in France.

The Nexen CRD350 rotary indexer was developed after a preliminary study which Mahr and Unicum completed jointly: it is capable of very high positioning accuracy during rotation and remarkable dynamic output.

Dynamic movements and a high positional accuracy

The rotary table is based on a roller-pinion system. The performance parameters of the rotary table are impressive: accurate to 35 arc seconds, maximum speed 94 rpm, maximum torque 564 Nm. Besides these advantages, the Nexen CRD350 is a very compact drive solution without backlash, requiring no maintenance or lubrication.

“The rotary table includes the Nexen roller-pinion system with a special ring gear and high-performance cross roller bearings for outstanding load capacity and rigidity. The system is mounted on a cast part.

The central passthrough of the annular design allows the essential access to the middle of the table, which is extremely convenient for routing electrical wires or inserting other machine components”, explains Alain Fourcroy, sales engineer for Unicum.

The ability to handle heavy loads with zero backlash

Says Jacques Loiseau, special developments manager at Mahr: “Demand and need are at above average levels at the moment. For further developments, we want the rotary table to be able to deliver the same accuracy with eccentric loading as well. At the moment, the overhung load is about 250 kg with an eccentricity of 200 mm. Despite the challenges, we were able to satisfy this requirement with complete success: the ability to handle heavy loads with zero backlash”.

Its low structural height and generally compact design make the ring drive system extremely versatile.

Apart from this customer-specific development for Mahr, Nexen CRD ring drive systems are used in a wide range of applications including cutting and gantry systems, medical devices, robots, machine tools, semiconductor production, materials handling and aerospace.