Cobots: for an Accurate Quality Control

Universal Robots provides some case histories with cobots: from the automotive sector to electronics, here are just a few examples of how it is possible to create safe, collaborative and easily integrated applications into the production process

by Massimo Brozan

In the ‘60s Armand Feigenbaum, General Electric’s quality manager, said that the costs faced by a company in the prevention of manufacturing errors were significantly less to those incurred in remedying them. It was necessary to work and invest in quality from the earliest stages of the industrial process. A decade later Philip B. Crosby, famous businessman and author, claimed that quality is not in itself a cost but a depreciable investment capable of guaranteeing better economic performance and, above all, of avoiding greater expenses in the error repair process.

These two scientists were amongst the first to make a link between quality assurance and business performance. Thanks to its qualitative consistency, robotics was nominated to perform quality control very early. Now let’s see some examples of with cobots from Universal Robots.

These are just a few examples of how it is possible to create safe, collaborative and easily integrated applications into the production process.

Electronics and high-tech sector in a Thai plant

Benchmark Thailand is a multinational company active in the electronics and high-tech sector, that has applied UR cobots in its Thai plant by automating both the assembly and quality control process of satellite modems. The company has installed four UR5 models (750 mm reach and 5 kg capacity on the wrist) and two UR10e models (1,300 mm range and 10 kg capacity on the wrist). The cobots pick up and insert the PCB boards in the modem body, place it in a screwing machine and subsequently enslave the machine for quality control. At the end of the control cycle (lasting about 15 minutes) if the test gives a positive response, the cobot unlocks the modem and places it in a storage rack, starting a subsequent cycle. The advantages recorded by the company concerned both productivity (+ 25%) as well as the optimization of the space available in the layout: these assembly and testing applications have allowed Benchmark to gain 10% more space.

French mechanical industry

BWIndustrie is a French mechanical industry that, after integrating various UR5e and UR10e models, installed an UR16e model, the most powerful cobot of the e-Series range and the most precise of its reach segment (850 mm per 16 kg of payload with a repeatability – at maximum extension and speed – of +/- 0.05 mm). BWIndustrie has integrated UR collaborative robots to perform various tasks, from deburring on fresh metal components of printing or turning to quality control on the components themselves. In the testing phase, the cobot picks up the piece at the end of the surface finishing cycle and places it in front of a vision system that performs the measurement and dimensional control of the piece itself. If the component is out of tolerance, the cobot places it in a special box. The cobot went to automate a task that previously was done entirely manually.

Two case histories in the automotive sector

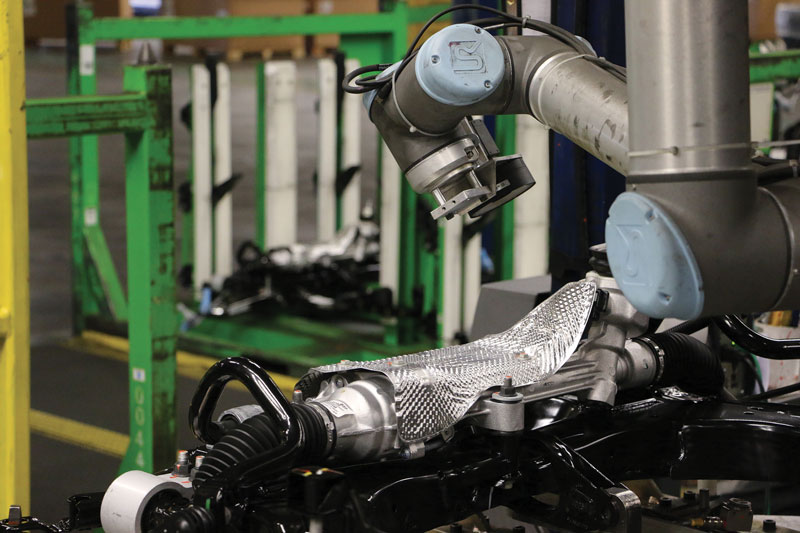

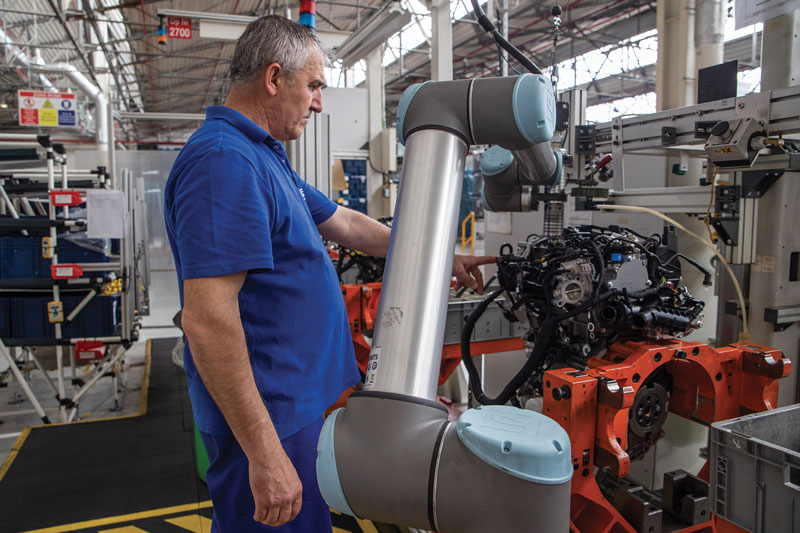

Now we’ll move to Comprenhensive Logistic, an automotive company. The assembly cycle of the motors is extremely complex, consisting of successive phases which must all be carried out with the utmost precision. Comprenhesive therefore sought an automated solution that guaranteed constant quality throughout all the steps. The testing at this stage was complex and hindered by the irregular geometries of the engine which made visual inspection of the assemblies very difficult. At this stage the company therefore inserted an UR10e cobot, that is fitted with an inspection camera on the wrist.

Thanks to the agile movements on the 6 axes and the generous radius of action, the cobot manages to inspect even the most hidden corners of the engine. Even Ford has used Universal Robots collaborative robots in its assembly and quality control processes. In particular, the Romanian factory in Kraiova has integrated the UR cobots for the execution of a simple task: after assembling the various engine components, the cobots fill the cylinders with oil to verify their watertight. Subsequently, a cobot with a UV camera installed on the wrist checks the external surface, checking for any cracks in the cylinder.