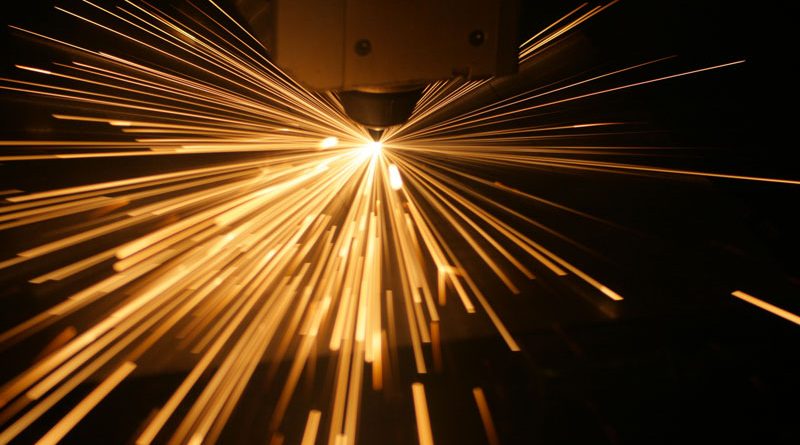

Laser Welding: The Power Measurement

Ophir explains the challenges of the laser in the e-mobility sector, and why the quality of the beam is so important. A first indication of whether a laser system is working exactly can be obtained through power measurements

by Christian Dini

E-mobility will ever establish a foothold in our country? One thing is for sure: the latest manufacturing concepts and the technologies of this sector are very tightly linked to laser welding.

Especially in electric cars, weight plays a major role. But although all the components are made to be as lightweight as possible, they still need to possess the required stability. Besides radical new design approaches, like those enabled through additive manufacturing techniques using lasers, the full potential of even traditional construction methods has yet to be exploited. For one, modern laser welding makes it possible to flexibly set welding spots and seams in automotive constructions. Plus, laser welding makes it possible to reliably process and join aluminum, high-strength steel and even new, fiber-reinforced materials. Along these lines, the production of battery systems for electric vehicles places particularly high demands on laser welding systems.

Laser power affects production quality

Regardless of the laser welding process involved, the quality of the weld spots or seams exerts a decisive influence on the safety and reliability of the parts produced, which in turn has a significant impact on the overall quality of the vehicle. But how can the manufacturers and operators of such equipment ensure that the laser systems are working correctly when they’re often incorporated into automated production lines? Anyone who takes for granted that lasers operate without wear and tear must simply accept losses in quality. Especially in production environments, the external influences on laser beam systems must be considered.

A first indication of whether a laser system is working exactly can be obtained through power measurements.

Sensors that operate according to the pulsed power method

Lasers with powers in the kilowatt range are frequently used in autobody construction. To measure these lasers quickly and reliably, Ophir, a brand of MKS Instruments, has developed sensors that operate according to the pulsed power method. Over a very short exposure time, the L40 sensor measures the energy of the laser beam and, when attached to a compatible assessment and display instrument, calculates the laser power. That means that, for a pulse lasting half a second (as an example), laser powers of up to 10,000 watts can be measured cost-effectively and without requiring any additional cooling on the sensor. This is of particular importance when welding batteries, because, it’s essential not to use water cooling.

Measurements in totally automated manufacturing

As soon as a laser is used in a fully automated environment – as is usually the case in automotive production – the requirements on the measurement technology change. In addition to pure power measurement, companies in this industry often require the instrument to be connected to a production data network: they need a compact, robust instrument that can be easily integrated into the fabrication process. Precisely for such applications, Ophir has developed Helios, which is based on the same pulsed power sensor technology.

The power gauge determines power and energy of industrial diodes, fiber or Nd:YAG lasers during a short exposure lasting between 0.1 and 10 seconds; it can calculate the total power up to a maximum of 12 kW or the total energy up to 10 kJ – without requiring air or water cooling. Due to the short measurement time power measurements can be carried out during the loading and unloading process.

Via Profinet, RS232 and USB interfaces, the measured values can be stored for evaluation as required.

As soon as the power of the laser on the machining plane drifts out of tolerance, immediate countermeasures can be taken.

A non-contact measurement method

Knowing the power of the laser at the machining level gives a first indication of whether it’s working within specifications. Details of the focus position – or changes in focus position over time – can only be determined with a device that measures the beam caustic.

Even a slight shift in focus position causes a significant change in power density. This in turn directly influences the quality of the weld seam, which, especially in sensitive welding processes, means that only very narrow tolerances can be permitted for changes in power density. Here too, the crux of the issue is the high power. For this purpose, Ophir has developed a non-contact measurement method based on the Rayleigh scattering.

How does the scattering of electromagnetic waves work?

The Rayleigh scattering describes the scattering of electromagnetic waves by particles that are smaller than the radiation’s wavelength. The electric field of the laser radiation induces an oscillation in the dipole molecule at the laser’s frequency, leading to elastic scattering at that same frequency. The scattered laser light is imaged from the side using a telecentric lens assembly on a CCD or CMOS camera. Each individual pixel in a single line of the CCD camera detects the scattered light as a measuring point of intensity in the beam profile. From these measurements, and using an integrated software with high accuracy, it’s possible to calculate beam and beam-quality parameters according to ISO 13694 and ISO 11146 standards. Since the systems of the BeamWatch product line are based on this measuring principle, they allow for real-time monitoring of the beam caustic. In this way, changes in the focus are made visible. As a plus, the lightweight and mobile measuring devices of the BeamWatch series can be easily transported if required.

Especially for the use in automated manufacturing processes, Ophir developed BeamWatch Integrated. This measurement device combines the aforementioned power measurements with the BeamWatch functionality and adds several interfaces that enable the integration in smart factory surroundings.