The Challenge of Vacuum Regulation

Specialized in technologies for creating and managing vacuum, Vuototecnica presents its catalogue of instruments. Let’s see together its vacuum switches, vacuum reducers and regulating valves. The goal is a perfect measurement

by Massimo Brozan

The regulation is a fundamental aspect of every circuit that operates with vacuum. Wrong measurements can generate large energy losses and can sometimes lead to pressure losses and even to more costly and time-consuming problems. Thanks to these challenges, Vuototecnica, specialized in technologies for creating and managing vacuum, created its catalogue of measuring instruments, thanks to its know-how gained in over forty years of activity. It includes vacuum gauges, pressure gauges, vacuum and pressure switches, vacuum control valves, and vacuum reducers.

Analogue or digital, compact and lightweight vacuum switches

In order to start working cycles, for safety, energy management and energy saving reasons, accurate instruments are needed to facilitate the measurement and verification of vacuum values generated by suction sources such as rotary vane pumps or pneumatic ejectors. Vuototecnica offers a wide range of vacuum switches: analogue or digital, compact and lightweight. If it is necessary to have a signal when maximum and minimum set values are reached for safety reasons, to start a work cycle, to control the grip of the suction cups or to supply compressed air to the vacuum generators, saving energy, Vuototecnica designed digital vacuum and pressure switches. The precision of these devices is high and their operation intuitive. The measured values are shown on the main display in two colors, red and green, which can be programmed by the user; the setting values can be seen on a secondary display. Two luminous indicators, relative to outputs 1 and 2, indicate the switching status of the two digital signals and the analog output. The switching outputs are independent. The switching points included within the scale values, as well as the hysteresis, can be programmed by means of buttons on the control panel, in a very simple and immediate way.

Other functions are also programmable, such as the comparison between two values, NO and NC contacts, choice of unit of measurement and blocking of values. They allow considerable energy savings and can be positioned anywhere, thanks to their robustness.

Some top of the range models

The 12 30 10 and 12 30 10A digital vacuum switches are perfect for measuring and controlling dry air and non-corrosive gases, ideal for signaling when maximum and minimum values are reached: for safety reasons or for starting and stopping a working cycle. Thanks to the hysteresis function, it is possible to manage the compressed air supply to the vacuum generators, with a great energy saving. These digital vacuum switches have been made in the form of a parallelepiped and are very compact and lightweight, so that installation is simple, in all positions. The interface is intuitive.

One of the top components is the digital vacuum switch 12 10 10. Its compact cylindrical configuration, with display, allows the immediate display of vacuum values making the use of a vacuum gauge superfluous. The device is programmable thanks to the control panel. Two LEDs, one green and one red, are integrated on the panel and indicate the switching status of the two digital output signals. The two switching outputs are also independent. Vuototecnica also offers the 12 05 10 P digital micro vacuum switch with reduced dimensions and switching times equal to less than 1 millisecond. It is suitable for installations near suction cups or where the vacuum distribution is restricted to very small spaces.

Finally, a pneumatic vacuum switch with very reduced dimensions, mini. This device is able to give or remove, depending on the model, a pneumatic signal when a certain vacuum level, previously set by the customer, is reached.

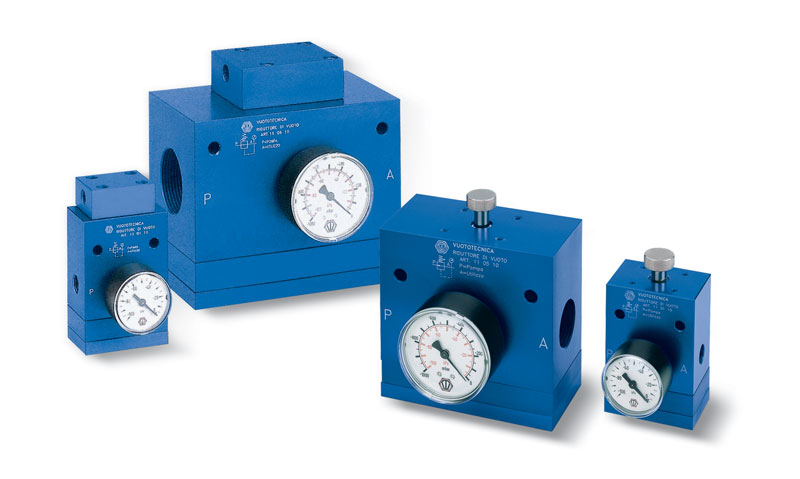

Manually and pneumatically adjustable vacuum reducers

A vacuum reducer is the ideal solution whenever there is a need to maintain a constant and adjustable vacuum level, even when there are oscillations of the pump; atmospheric air never enters the circuits and therefore products are not deformed by vacuum.

Vacuum reducers find their greatest application on centralized systems. In contrast to the pressure-limiting valves, they do not introduce air into the circuit, and thanks to them it is possible to create several pick-up points at different vacuum values from a single central vacuum source. They are able to regulate the vacuum level and keep it constant at the required value. Vuototecnica produces two types of reducers: manually adjustable vacuum reducers, with knurled screw, which allow to regulate different vacuum values, even close to atmospheric pressure; pneumatically controlled vacuum reducers. These last products can also be installed far from the control point, as long as there is a pressure regulator on the control panel to adjust the vacuum values.

The pneumatic reducers operate by acting on the compressed air pressure of the pneumatic cylinder supply in a proportional way: the higher the pressure, the higher the vacuum level and vice versa. The reducers avoid vacuum deformation of objects, and are therefore suitable for gripping and releasing fragile or deformable parts.

Vacuum regulating valves

If you need to adjust the vacuum on rotary vane suction pumps or on liquid ring pumps, side channel impellers or lobe pumps, Vuototecnica offers its vacuum regulating valves which are characterized by their ease of use and excellent sealing. When the selected vacuum level is reached, these valves introduce atmospheric air into the circuit, to prevent the set value from increasing and keep it constant, on circuits with a single vacuum pump and a single use (or several uses at the same vacuum level).

The regulation is obtained by rotating the knurled bushing in both directions; the very fine threading of the valve guarantees a precise calibration. They also have a seal gasket in nitrile compound or in Viton, in case of need of use at high temperatures or in presence of chemical agents. The seal is directly vulcanized on the valve buffer and is able to ensure maximum tightness when the desired vacuum level is reached. On the market are now available other metal to metal sealing valves, with relative risks of leakage. They also have a seal gasket in nitrile compound or in Viton, in case of need of use at high temperatures or in presence of chemical agents.