A Range of Gauges for Every Requirement

Sermac is the Italian representative of Microtech, a Ukrainian company specialized in the metrology sector. The new stainless steel digital gauges with IP67 degree of protection, ideal even in the most difficult workshop environments, stand out in the product range

Metrology plays a fundamental role for every company, whether small or large. This is especially so considering the transformations generated by the Industry 4.0 paradigm, which leads companies towards increasingly automated and interconnected solutions. Metrology and Industry 4.0 can no longer do without each other, representing the perfect combination of those technologies which allow to acquire and manage data, an essential element of the production process and, at the same time, the target and the instrument of measurement. This is why metrology is now an integral part of the production cycle, alongside every machine tool. For instance, a simple gauge, equipped with a micro-computer, communicates and transmits data via Wi-Fi to other devices, which process the measurement in order to make the processes efficient and create quality. To “ create metrology 4.0”, however, the most innovative tools must be available for a more competitive production. In the metrology sector, Microtech is among the emerging companies.

A specialized Ukrainian company in the field of measurement

At its headquarters in Kharkiv, Ukraine, Microtech studies and designs new solutions and new measuring instruments. The company is ISO 9001:2015 certified and the entire production process is controlled internally. Every product undergoes strict inter-operational testing with a 100% final test performed on every instrument manufactured, which takes place in an ISO 17025 certified ilac-MRA calibration laboratory. In addition to a wide selection of products, the research, design and IT departments develop special metrology instruments according to specific customer requirements.

Microtech is an international company, present worldwide with over 40 direct distributors. Represented and distributed exclusively in Italy by Sermac, it is a partner capable of accompanying the technological evolution of measuring systems with a wide range of high precision and quality instruments, integrated with flexible and easy to use software solutions.

“ Microtech’s proposals – Alberto Gillio Tos, Sermac’s director, declared – consist of hundreds of articles able to offer a complete range of models for the workshop, metrology rooms or for use on dedicated benches, with numerous instruments equipped with fixed or Wi-Fi connections to data processing equipment, in an Industry 4.0 perspective”.

Continuous and patented innovation

Since its foundation in 1995, Microtech has focused on developing know-how. A philosophy highlighted by more than 75 international patents for high precision measuring instruments. The most significant ones have been filed in the last six years, such as computerized instruments with color touchscreen microcomputer, equipped with special functions such as: formula, Go/NoGo, max/min, timer, memory, wireless and USB data transfer, temperature and mathematical error compensation. The use of innovative computerized electronics on classic metrology products allows sub-micron resolution on comparators, micrometers, thickness meters, gauges and micron accuracy on gauges and altimeters. Microtech’s computerized electronic system offers many advantages in usability. There are also gauges equipped with measuring force control. The force control modules up to 8 N developed by Microtech are applied to high quality instruments which can achieve an accuracy of up to 5 microns. For the measurement of soft materials, gauges with low force control up to 0.8 N are offered. This is followed by a series of instruments developed for operators with disabilities such as voice gauges, voice comparators for tablets and voice micrometers for tablets. Other innovations are also available for out of the ordinary measurements such as: wide-range micrometers up to 10,000 mm, gauges with a range up to 20,000 mm, clamps with jaws up to 1,000 mm, internal 3-point micrometers for ranges up to 3,000 mm, all with modular construction for easy transport, and gauges for holes with a measuring range up to 1,000 mm and depth up to 10,000 mm (they can be equipped with a camera system for positioning inside deep holes). Finally, slide body for gauges with self-lubrication system allowing maximum smoothness of the guides for more precise measurements, and gauges for tablets with integrated computers and pyrometers.

Microtech’s computerized electronic system.

All Microtech products meet strict manufacturing standards.

Instruments with computer module for data connection.

A complete range of instruments for use with free software

The Microtech production program includes a complete range of instruments. From digital gauges and micrometers for indoor and outdoor use to comparators, altimeters, bore gauges, protractors, radius gauges, thickness gauges and so on, in the most varied implementations and with relative accessories. Each instrument is proposed in different versions to better meet the needs of the various types of users, such as in production phases, in tooling, control during assembly, metrological rooms and so on. The instruments are manufactured according to the latest regulatory standards, and accompanied by quality and guarantee certification generated by the Microtech calibration laboratory at no additional cost.

All instruments equipped with a computerized data connection module may be used with the free Microtech software to transfer measurement results to computers, tablets and smartphones. The software is available for Windows, Android and iOS operating systems. The module allows long range data transfer over a distance of up to 50m. The software can control with color limits (Go/NoGo), save graphs, export measurement results to *.xls or *.csv files and save data via timer.

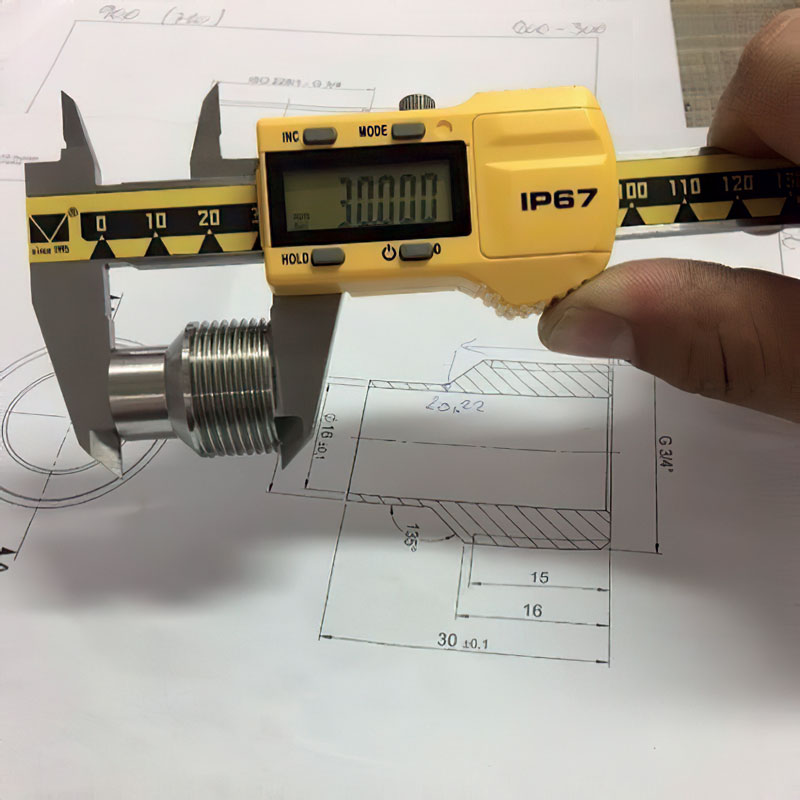

New IP67 gauges with force control

New digital stainless steel gauges have been developed with a module equipped with Swiss Sylvac electronics with IP67 degree of protection which guarantees high quality, greater precision and easy use even in the most difficult workshop environments.

The gauges are equipped with a special aluminium alloy module called “Force” patented by Microtech, which allows the control of the measuring force between the nozzles so that the measurement is always carried out with the same recommended 8 N force.

This technology improves the accuracy of the gauge in terms of measurement repeatability down to 10 microns on the external nozzles.

The slide body is also equipped with a special self-lubrication system patented by Microtech: it guarantees a continuous presence of an oil film on the guides which increases the smoothness and fluidity of the movement.

Sylvac electronics allows some convenient functions: mm/inch conversion, instrument zeroing in any position, preset, Force module force control setting, OPTO RS232 data output or wireless option, and automatic stand-by mode after 10 minutes of inactivity.

Power is provided by a standard CR2032 button cell battery, sufficient for up to 8,000 hours of instrument use. Replacement only takes a few minutes.

Three sizes available in a compact design

The range is developed in three sizes for a range in measurable lengths of 0-150, 0-200, 0-300 mm, external nozzle lengths of 40, 50, 60 mm, internal nozzles of 16, 20, 20 mm and depth rod with 4×1.4 mm section. Variants are available with external and internal nozzles which may be coated with carbide inserts. The gauge has a resolution of 0.01 mm and the accuracy is +/-0.010 mm. The instrument is light, ergonomic and practical, with a compact design and high contrast colours allowing visibility of the instrument. The large display with sharp LCD screen features large fonts for easy and precise measurement readings. All controls, both electronic and mechanical, are conveniently operated and selectable via touch commands. The operator can easily take single-handed measurements also thanks to the smoothness and fluidity of the self-lubricated slide. The range of gauges with force control is completed by the Micron models which, with the same technical characteristics described so far, differ for a resolution of 1 micron and extra/high accuracy of +/-5 micron on the external nozzles.