A Single Instrument to Monitor Aqueducts

In an aqueduct there are many parameters which need to be monitored and controlled, both qualitative and quantitative, coming from different systems: Ge Proficy Operations Hub, distributed in Italy by ServiTecno, is a client which acts as a single point of aggregation

The supply of safe drinking water is one of the Millennium Development Goals set out by the United Nations in 2015. Two topics are currently on the table of the aqueduct managers, not only in Italy and Europe but globally: “Water Safety Plan” and “Water Leakage Management”. Both concern compliance with regulations aimed at improving the product/service they offer, and have a direct impact on certain aspects which are vital for those who run an aqueduct: water quality, plant efficiency to guarantee continuity of service, reduction of leaks and optimisation of supply costs.

What are the actions of the WHO and the European Commission

On the one hand, the World Health Organization (WHO) introduced in 2004 the “Water Safety Plans” model as the most effective means to systematically guarantee the safety of a drinking water system, the quality of the water supplied and the health protection of consumers/users/citizens. The “Water Safety Plan” became an integral part of European legislation with Directive 2015/1787, which amended Annexes II and III of Council Directive 98/83/EC concerning the quality of water intended for human consumption, and allowed individual states two years to adapt to the new legislation. Having recently become part of the Italian legislation on the quality of drinking water, the Water Safety Plans are in the process of being adopted by local aqueducts; in the undesirable case that management of drinking water emergencies might be needed, they represent an example of the versatility of the instrument in the scenario of risk analysis applied to drinking water. On the other hand, the Environment Directorate of the European Commission published in 2015 the document “Good Practices for Water Leakage Management”, an updated technical and regulatory reference for leakage management for all European managers and regulators.

A single point of aggregation

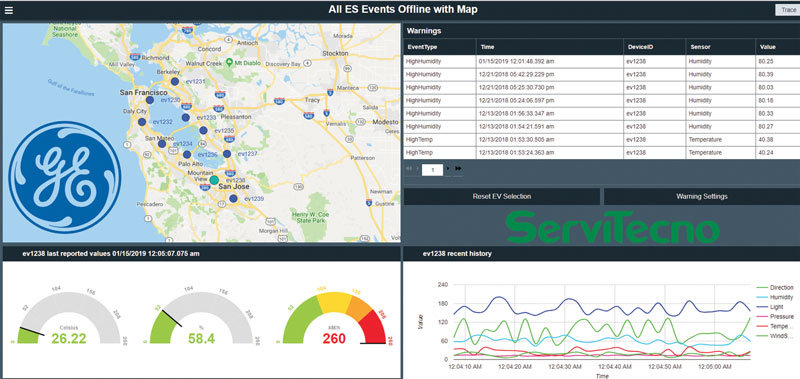

It is therefore clear that in an aqueduct there are many parameters to monitor and control, both qualitative and quantitative, coming from different systems. The need therefore arises to concentrate the vision of these parameters in a single point of aggregation and visualization of facts and information coming from plants and analysis laboratories, where it is also possible to extract Analytics and KPIs. We are talking about Proficy Operations Hub, a GE Digital solution distributed and supported in Italy by ServiTecno, designed to improve access to production data by providing operators, wherever they are, with the necessary information to react to events effectively. It is a client capable of retrieving data from heterogeneous sources. It is therefore not designed for supervision (although it has the possibility to insert entire SCADA screens if they are on the web), but to visualize and compare historical and real-time data from different plants or similar systems located in different areas. Thanks to the functionalities offered by this solution, operators can quickly and intuitively understand what is happening in production, and develop interventions to solve problems and improve productivity.

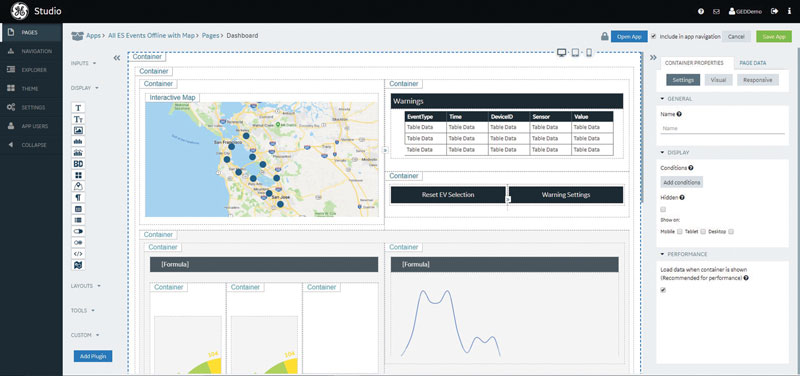

An easily configured dashboard

With quick and easy configuration, the Proficy Operations Hub allows companies to create intelligent industrial applications to improve data connectivity, aggregation and visualization. Each dashboard can be created through simple drag & drop actions, and could be implemented directly by plant managers who often do not have the necessary technological skills. Available in both Windows and Linux versions, the Proficy Operations Hub allows workgroups at any level of the corporate organization to increase operational efficiency and make decisions based on real-time field data, as well as on the historical series generated by Historians, MES, LIMS and such like. The solution enables improved collaboration and the creation of an easily accessible digital operations center. Thanks to its ability to quickly create screens, and to organize them in a way that is adaptable to the context, operators can react quickly to events, by means of centralized visualization and digitization of processes. The Proficy Operations Hub uses development tools which do not require code writing to quickly assemble high-performance Web-based applications, enabling collaboration and continuous process improvement. The new 1.5 version integrates the Advanced Historian Trend Analysis tool: with dashboards designed to visualize trends and KPIs from historical data, contextualized data analysis is performed based on the model describing the company’s assets, and the understanding of problem causes and collaborative analysis is improved.