Smart Technologies for Industrial Machine Vision

Vision systems, suites of software and libraries, industrial 3D cameras: here are some solutions distributed in Italy by Visionlink, a company that selects products for image acquisition and processing on the international market

Specialised in solutions for imaging applications, Visionlink provides products, technologies and consultancy in the field of image acquisition and processing systems in order to realize vision systems. The company offers a complete range of hardware and software solutions, selected and guaranteed to obtain high performance and reliability. Let’s see some of the top products distributed in Italy by Visionlink.

Vision systems with wide field of view

Let’s start with In-Sight 9000 by Cognex, a line of ultra-high resolution vision systems for wide-field inspections. It consists of a linear smart camera (model 9902L) and two matrix cameras (model 9912 monochrome and 9912C color). An IP67 enclosure protects the system from liquids and dust. With a resolution up to 12 MP for the area scan cameras and up to 32 MP for the linear model, the new smart cameras feature highly detailed image capture and processing capabilities. The wide field of view, which is characteristic for all In-Sight 9000 vision systems, allows large objects inspection without precluding exceptional image resolution, giving the opportunity to install the vision system away from conveyor belts, and to maintain a safe distance from hazardous equipment.

Let us now describe the In-Sight 9902L linear scanning vision system, designed to inspect large, cylindrical and continuously moving objects. It captures 2,000 pixels with each line, providing 32 MP (16,000 lines) images that allow vision tools to perform highly detailed inspections. Each line of pixels can be captured at 67,000 lines per second to be aligned with the speed of the fastest production lines. The 9902L requires only a small view of the target part, making it the ideal choice for installations with limited field of view or mounting space. The In-Sight 9912 area scanning vision system, available in monochrome and color, is ideal for inspection of large fixed parts. With 12 MP (4096×3000 pixels) resolution, it captures detailed images for high precision measurements and also features HDR+, which extends the boundaries of High Dynamic Range technology to improve contrast across the entire image without reducing capture speed. All Cognex cameras are equipped with the In-Sight EasyBuilder interface, a suite of vision tools that guides operators through an easiest step-by-step configuration process.

Libraries for 3D image processing and analysis

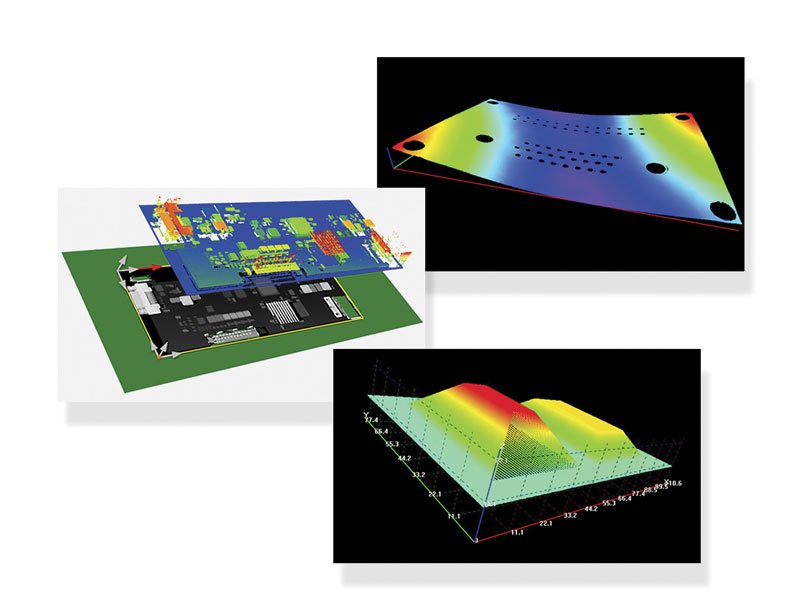

Open eVision by euresys is a suite of software and libraries dedicated to image processing and analysis. Thanks to the tools available you can quickly design and develop image processing software using the C++ or .NET languages.

Inside, in addition to the basic vision libraries for image filtering and enhancement, BLOB analysis and pattern matching, we find other ones optical character recognition (OCR), print inspection and 1D/2D barcode reading. The solution is completed by the latest generation libraries for 3D scanning and 3D pattern matching that include laser line extraction and calibration, point cloud processing and management, point cloud or ZMap detection and measurement of 3D objects, as well as those equipped with artificial intelligence algorithms for object classification and detection of defects often not detectable with traditional machine vision techniques. In particular, the use of the Easy3DObject library allows to detect 3D objects within Point Cloud and ZMap, using customizable ROI for object extraction. Moreover, this library provides algorithms for the measurement of size, volume, area, orientation of the detected objects, returning the measurements in real units (such as mm or micron) and giving the possibility to filter the extraction results through detection criteria such as width, height or volume of the object, thus limiting the extraction to the objects of real interest.

Cameras with a new image sensor

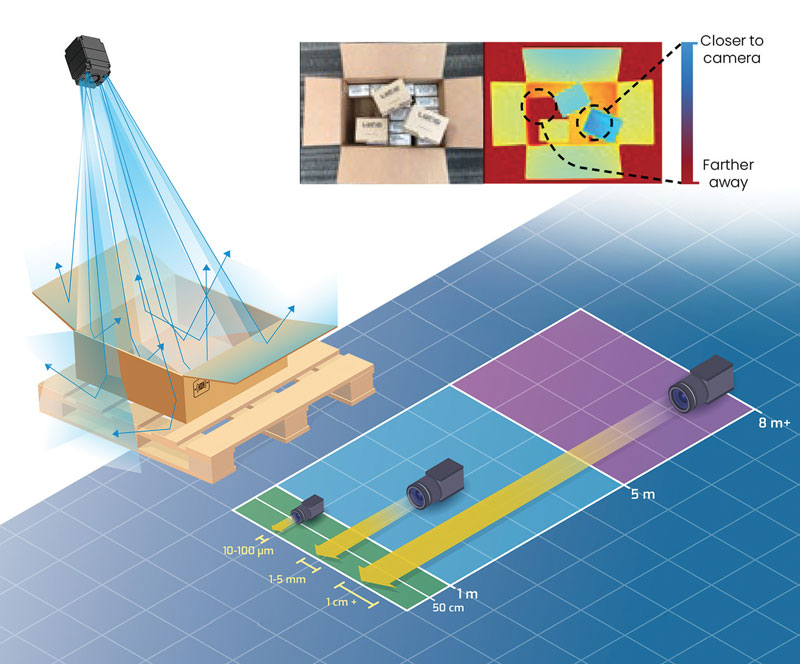

The Helios by Lucid Vision Labs are compact, high-precision industrial 3D cameras incorporating Sony’s new Time of Flight DepthSense™ IMX556PLR image sensor. Equipped with integrated on-board processing functions and compliant with GigE Vision 2.0 and GenlCam3 standards, the Helios are offered in three versions: the standard model HLS003S-001 (the first in the series), the new entry Helios2, and the Flex for OEM applications.

All provide a depth map with a resolution of 640×480 at a maximum measurement distance of 6 meters, obtained through four 850 nm VCSEL laser diodes. The housing models offer a rugged design with M12 Ethernet connector and connection up to 100 m, making them ideal for production and logistics applications. The Helios Flex board camera is designed for OEM applications in embedded vision systems. Its MIPI digital interface allows connection to major embedded platforms. Helios2 is the latest in the series, with improved performance in 3D reconstruction, reaches a working distance of up to 8.3 m and a frame rate of 30 fps, and enables sub-millimetric accuracy. It also features improved optics for increased light sensitivity, and improved geometric calibration. It boasts a rugged design with IP67 protection rating that preserves the lens, GigE Vision PoE interface and M12 industrial connector. Lucid’s Arena SDK, which includes easy controls, provides customers with easy access to the latest industry standards and software technologies, and supports Windows, Linux 64-bit and Linux ARM operating systems, and C, C++, C# and Python programming languages.