Smart Couplings and the Challenges of Industry 4.0

The AIC coupling form R+W is a smart component with integrated sensors able to measure, collect and transmit data during its operation, in full compliance with Industry 4.0 principles. Here are the main benefits and fields of application

With its support systems, the AIC (Artificial intelligence Coupling) coupling from R+W makes it possible to meet the challenges of Industry 4.0 in unique ways. In the realization of a given kinematic chain, determining data in operating conditions, measuring them directly inside the transmission, makes it possible to accurately estimate the actual state of the machine and carry out the appropriate maintenance programmes. Figure 1 shows a section of the AIC coupling with the main electronic components. The structural choices made by R+W for the construction of the housings of the measuring systems have made it possible to contain inertia and overall dimensions. The AIC coupling has a particular modular structure, easily integrated in the spacers, which allows its integration with other existing R+W products. These structural choices allow the use of the AIC coupling also in heavy duty applications. It’s easy to install, thanks to the absence of additional flanges, and the sensors are well protected thanks to the special sealing.

Functions and connectivity of the coupling

R+W has integrated state-of-the-art sensors and solutions into the new AIC coupling. The heart of the system is the electronic components, which integrate different types of sensors: strain gauges provide a measurement of localised torsional strain (or overall torsional deflection) starting from that of mechanical stress; accelerometers detect and measure structural oscillations and vibrations, referring to the totality of the obtained kinematic chain; the gyroscopes measure the angular velocity, generally consisting of a 3-axis accelerometer or a series of single-axis accelerometers arranged in a radial direction, in a number suitable to provide a reading extracted from the average of the readings of the individual component accelerometers. In addition to the integrated sensors, there is an electronic board mounting a microcontroller, a Bluetooth radio module and a signal amplifier, providing the connectivity functions that make the AIC coupling a smart component. Its power supply is provided by a lithium-ion battery; the wireless charging system allows the AIC coupling to operate and transmit data continuously, without time limits linked to the battery, charged during normal operating conditions.

The main fields of application

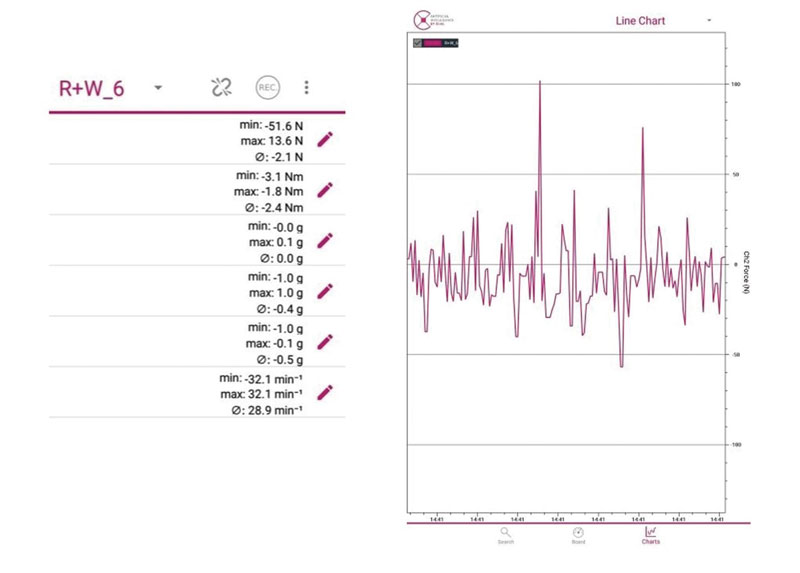

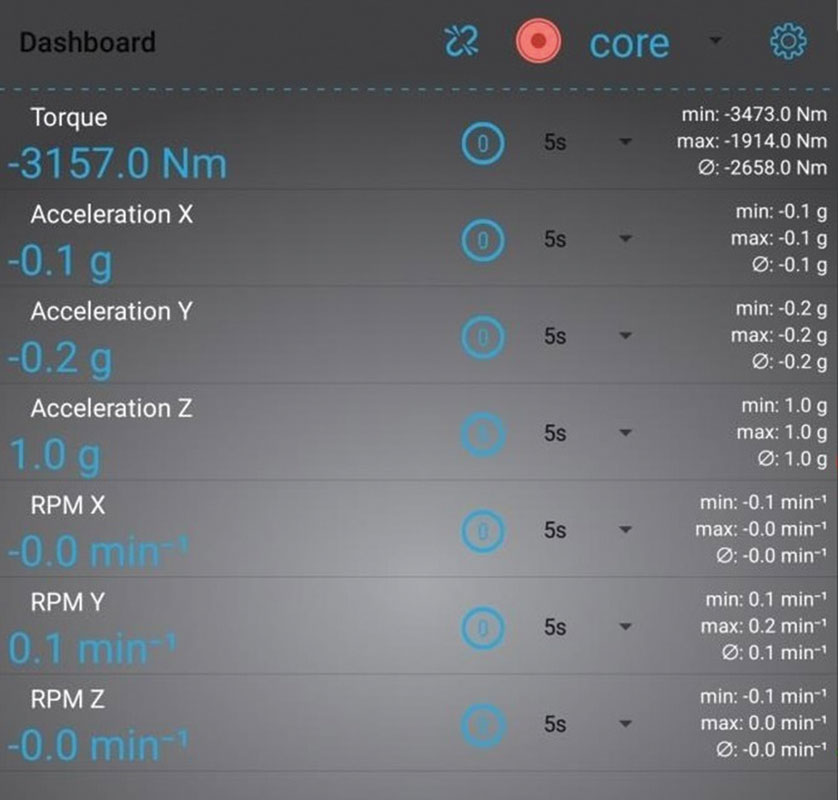

With its ability to perceive, interact and interconnect, the AIC coupling is designed for production lines operating automatically and adaptively and for all IoT Assisted Production contexts. Data collection concerns: torque (error: <1%), speed (error: <3%), vibration (error: <3%), compression / extension (error: <3% for calibrated LP combinations up to 1000 Nm). The representation of the measured data is realized through a special app for Android mobile devices (figure 2); the same data can be recorded and exported in csv format. The app’s dashboard provides a complete overview of the measured quantities, including maximum and minimum values and their average (figure 3). The graph display modes are shown in figure 4; the app gives you the ability to superimpose multiple different curves into a single graph, and display data measured by multiple AIC couplings operating at the same time. The aggregation of the measurements allows a better evaluation and understanding of the behaviour of the rotating bodies making up the transmission. The fields of application envisaged for the AIC coupling include: predictive maintenance activities, test setups, verification of theoretical design data, real-time control of parameters such as vibrations, temperatures and recall forces.

What are the advantages?

There are many advantages that can be achieved with the use of the AIC coupling: continuous monitoring of use in real time, application-based predictive maintenance, quality monitoring through end-of-line control, validation of design data with actual data measured under operating conditions.

The use of the AIC coupling facilitates the entire life cycle of a single product or a range of products, in relation to its use in kinematic chains present in critical production machinery. R+W confirms its commitment to provide reconfigurable, flexible, collaborative and customisable support services on request. The results achieved with the AIC coupling make it an efficient component also in the technology of cyberphysical systems, for which physical objects and software platforms are integrated to exchange information in an optimal way.