Smart Sensing for an Intelligent Factory

At Festo, the proposal for increasingly optimised sensors and the integration of AI into new systems is already a reality. Intelligent data monitoring plays an essential role in the transition from the traditional factory to the Smart Factory

In the age of digitisation in which we are living, intelligent data monitoring is the key to the success and competitiveness of companies. Through Apps and data by Civil Protection agencies, for example, we are able to map a process more clearly, so that we can try to predict its development and respond quickly, as in the case of the Coronavirus pandemic. At the heart of all of this, there is data collection, which in the world of automation translates into the use of devices and sensors.

Technology and people work together for a more transparent process

Smart Sensing plays a key role in the transition from traditional to Smart Factory. Compared to a few years ago, the joint adoption of different types of sensors is revolutionary, an important innovation enabling improved interconnection and cooperation between components and persons in operational processes. It is above all in this sense that, as the main enabling technology of a 4.0 scenario, an exchange of information occurs, which is not limited to the physical boundaries of the factory, but also allows to manage production and data from and to the outside. This intense collaboration between technology and persons makes the process more transparent, productive and profitable. An evolution which opens up new ways of working in the factory, removing constraints and creating new opportunities, both operational and business. A process requiring new skills to fully exploit their potential.

Sensors and artificial intelligence: when there is strength in numbers

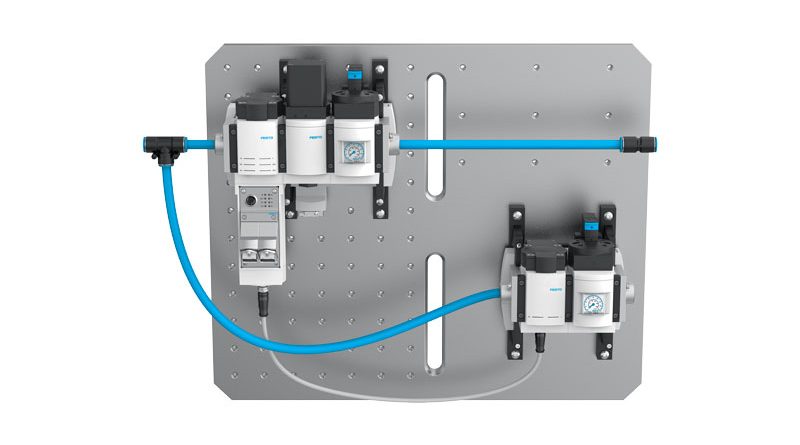

Sensor technologies and Artificial Intelligence (AI) solutions have paved the way for a new, more operational and conscious productivity category. They can therefore be considered the driving force of the industrial revolution, which has brought digitisation into an area linked to classic production and distribution logic. With ever more sophisticated sensors and data analysis, technology has come to introduce intelligence into factories and warehouses, overturning traditional processes. At Festo, the proposal for increasingly optimised sensors and the integration of AI in the new systems is already a reality, carried out with the aim of further increasing the productivity of its customers through machines designed for self-learning. Sensing is also at the basis of Energy Efficiency: through the use of devices now completed with integrated sensors, consumption may be monitored with certainty to try to optimise and predict it through the use of AI. Festo in this respect allows monitoring via MSE6 devices such as E2M, C2M and D2M at line level, and VTEM at a more precise level. Through the connection of other sensors, data is available to optimise quality and production. This is the case of SDAP, which is used to detect the position of SFAB series actuators and flow monitoring sensors, which use IO-Link point-to-point communication.