Transmitting Industrial Data in the IT World

Distributed in Italy by ServiTecno, DataHub is a middleware solution which safely enables the highest possible connectivity between the world

of production and business management. All this by creating a bridge between IT and OT

For the transition to the intelligent factory, based on the use of industrial data to support business decisions, proper integration between the worlds of production and management systems, and between these and cloud data analytics systems, is essential. That having been said, taking data from a sensor and bringing it out of the Operational Technologies (OT) domain may be not only complicated but even dangerous. On the one hand because the “translation” of the OT datum into a datum significant for the IT world is not banal, on the other hand because to take a datum out of the realm of machinery it is necessary to open its doors, with all the risks in terms of IT security. To solve these problems, the Canadian company Skkynet (distributed and supported in Italy by ServiTecno) developed DataHub. This is a versatile, powerful and fast middleware solution which integrates data coming from a series of sources, offering the possibility to use them in a simple and safe way. This software, which has a user base of 1,600 customers worldwide with 16,000 installations, allows to safely enable the maximum possible connectivity. Installation and connection are carried out in just a few minutes, and with the protocol used communications are real-time.

The languages of the OT and IT world translated into a unified data set

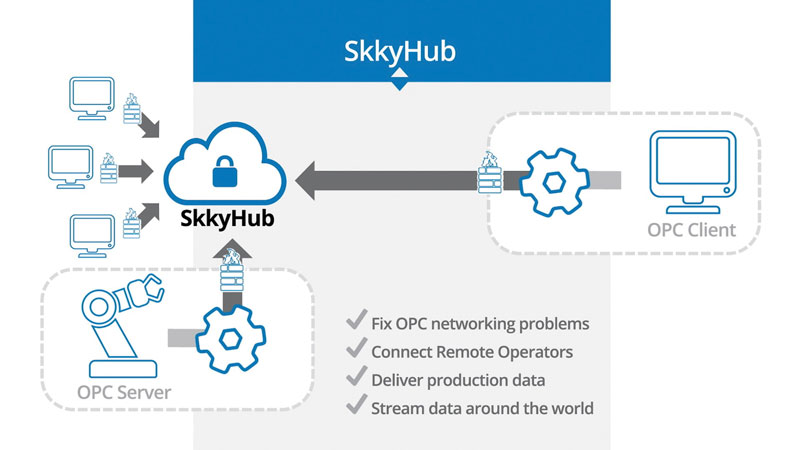

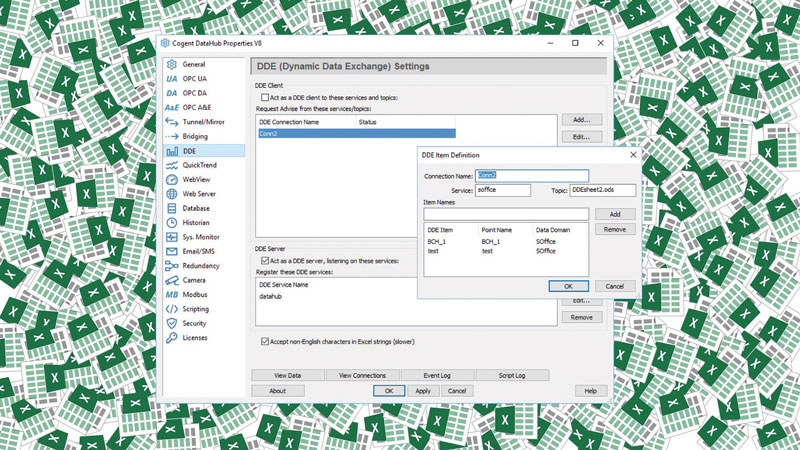

With DataHub it is possible to make bi-directional real-time connections between the production world, that is, OPC UA and Classic (OPC DA) clients and servers, and any SQL database, MQTT client or broker, but also Excel spreadsheets and cloud platforms such as Azure IoT Hub, Google IoT, Amazon IoT Core. DataHub is able to understand the different languages spoken in the OT and IT world, translate them quickly and create a single unified data set available to any analysis or visualization platform. Supported protocols include OPC UA, OPC Classic, MQTT, Modbus, DDE, TCP, ODBC, HTTP, XML and more. Thanks to these properties, DataHub meets a variety of requirements. First and foremost, it allows industrial data to be used to monitor and control plants. The integrated HMI web interface (WebView) makes it possible to create and display pages in a web browser. Then DataHub can record data in any SQL database, create a secure connection to any Industrial IoT platform, activate actions based on data variations, and finally perform real-time analyses with Microsoft Excel, one of the tools preferred by companies for data collection and analysis. With the tunneling feature, network connectivity is easy to configure, secure and robust even for protocols which are difficult to connect, or which are based on unsecure architectures. Data can be integrated without exposing networks by using DHTP to optimise security, resilience and data throughput.

Using Excel for data sharing

Thanks to an add-in it is possible to collect and analyse production data in real time with Microsoft Excel, calculate statistics and create charts. Data are dynamically inserted into Excel cells with update speed in the range of milliseconds. In this way, the cells update automatically when the underlying source data changes. Besides, this solution supports the use of data by multiple users, offering the possibility to choose only the necessary data to share from each workbook. Since data are shared and not workbooks, all users can have their own personalized view. Other positive aspects of DataHub include, as we anticipated, its speed: it can handle over 50,000 value changes per second of the points which generate the data. It also allows all functions to be integrated into a single user interface, and can be adapted to almost all industrial systems. It can connect to SkkyHub, Skkynet’s dedicated Industrial IoT network, which allows any combination of in-plant, cloud or hybrid connectivity configuration.