Another Novelty of the Metrology Suite

PolyWorks MS 2021 from InnovMetric is the latest release of its 3D dimensional analysis solution. It delivers powerful curved surface analysis tools, and increases the efficiency and repeatability of their 3D measurement operations

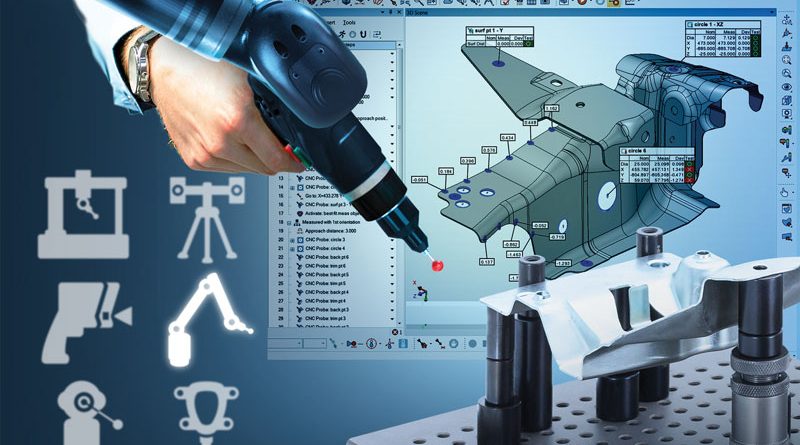

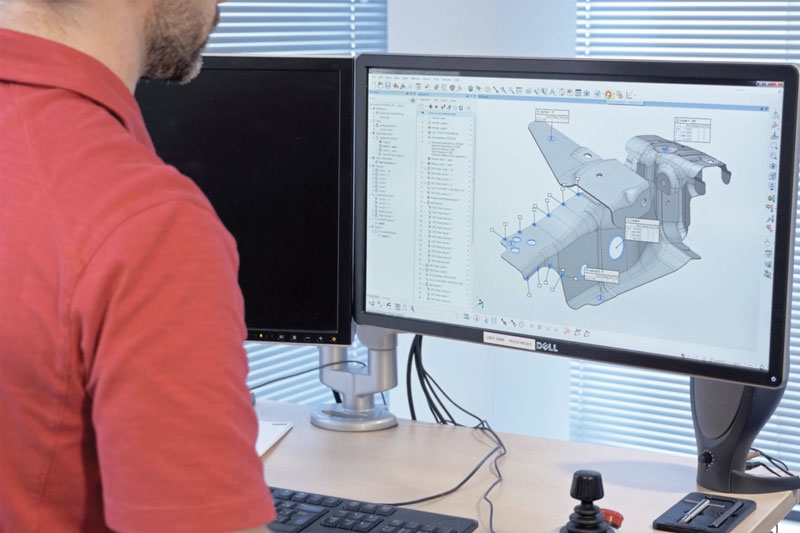

Specialized in smart 3D metrology software solutions, InnovMetric presents PolyWorks MS 2021, the latest release of its 3D dimensional analysis and quality control solution. The curved surface analysis toolbox offers a built-in isotropic surface defect detection technology that identifies anomalies such as bumps, dents, scratches, and cavities directly on scanned data, without the need for a reference CAD model. Leveraging the Microsoft HoloLens mixed reality devices, PolyWorks Metrology Suite 2021 provides digital gauging operators with automatic mixed reality photo capture to ensure measurement traceability, and accelerates assembly building through on-screen guidance powered by holograms. This new major release also offers users a more comprehensive offline CNC CMM sequencing solution thanks to the increased intelligence of its assisted sequencing technology, enhanced support for CMM components from all major brands, and a DMIS exporter. “PolyWorks MS 2021 leverages new and emerging technologies that optimize the performance and usability of our solutions” said Marc Soucy, President of InnovMetric. He also underlines some important topics: the addition of dimensional analysis tools that boost user productivity, the integration of mixed reality technology in standard 3D measurement workflows, and enhancements to their offline CNC CMM solution, that provide important measurement sequencing capabilities.

A quick control analysis

With this latest PolyWorks MS release, users benefit from powerful tools to make quick work of analyzing the quality of a wide variety of curved surfaces.

Bumps, scratches, dents, and cavities in curved or planar surfaces of scans can be located using the isotropic surface defects color map tool. 2D sheet metal cutouts can be fully inspected with the GD&T line profile tool. The GD&T line profile tool can analyze sections of extruded or lofted parts. By using the local flatness tool, the area of greatest deviation on high-precision contact surfaces, such as flanges, can be found. Moreover, flush&gap measurements are possible on assembled vehicles, even when certain areas cannot be measured, by extrapolating measured data using CAD models.

The benefits for the operators

Manufacturing organizations can increase the efficiency and repeatability of their 3D measurement operations thanks to technological aids added to measurement processes. Digital gauging traceability is available by capturing and automatically storing a mixed reality photo when measuring a dimension with a digital gauge. Digital readouts, axial deviations, and guidance arrows can be displayed as holograms in the operator’s view to help precisely position a machine, a tool, or a fixture. Measurement operations seamlessly incorporate other digital enterprise solutions, by using macro scripts that self-trigger before or after certain operations are executed.

A comprehensive toolbox

This latest release adds a new level of intelligence to PolyWorks|Inspector’s assisted sequencing technology and extends the universality of its offline solution. The assisted sequencing technology can automatically determine if multiple tool orientations are needed to measure an object and configure object measurement methods. The assisted sequencing and collision avoidance and analysis technologies are compatible with Renishaw controllers. Hexagon and Zeiss inferred probe heads and laser scanners are available in the hardware catalogs when creating a sequence offline. PolyWorks MS CNC CMM measurement sequences are exportable to a standard DMIS file to accelerate sequence creation in legacy CMM software.