Industrial Sewing Machine Solution

Delta Motion Control provides an industrial sewing machine solution for the garment industry. In addition to ensure the high-speed control and communication, it enable to set up parameters and monitor the production

in real time

by Massimo Brozan

Specialized in the automation sector, Delta has provided a European garment manufacturer with an efficient industrial sewing machine for automatic trouser pocket setting. The garment industry is a traditional industry with a long history and well-developed industrial structure. However, to cater customers’emerging ordering habits and higher requirements of quality and efficiency, the production mode has shifted from standard mass production to customized production with small quantities and wide varieties.

Frequent changeovers, complicated production processes and high labor costs have increased management costs, so garment manufacturers are starting to implement automated equipment and are seeking to upgrade production solutions. Replacing manual labor with automated machinery does not only shorten production time and save direct costs, but also achieves flexible manufacturing and maintains consistent and meticulous quality for finished garments.

High-speed control and communication

To fulfill the requirements of automated sewing, Delta has provided the client with an industrial sewing machine for automatic trouser pocket setting.

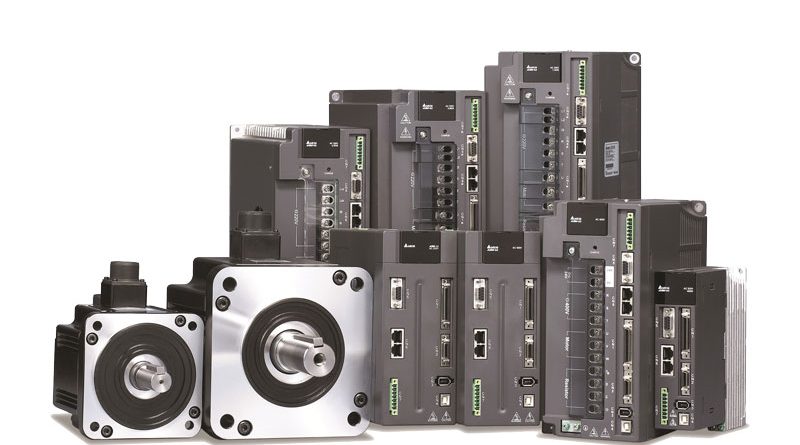

This solution uses the Delta Network Type Advanced Slim PLC DVP-SE Series as master control, connecting the Delta AC Servo Drive & Motor ASDA-A2 Series via CANopen communication.

The ASDA-A2 servo drives control two axes of the ECMA series servo motors for sewing operations.

Via the Delta 4.3-inch Widescreen HMI DOP-B Series, users can set up parameters and monitor the real-time sewing process to ensure successful production.

In actual application, Delta’s solution brings the following benefits, first of all high-speed control and communication.

As we explained above, this solution adopts the Delta Network Type Advanced Slim PLC DVP-SE Series as a master control.

The DVP-SE Series delivers up to 0.64 μs high execution speed with built-in Mini USB, Ethernet and two sets of RS-485 ports.

The built-in IP Filter functions as a firewall for first line protection against malware and network threats. The DVP-SE Series supports the DVP-S Series’left-side and right-side modules for various extensions. In this solution, it controls AC servo drives with the high-speed extension module CANopen Master DVP-COPM via CANopen communication, to achieve highly efficient sewing machine operations.

Real-time setting and monitoring

Another benefits is real-time setting and monitoring. Delta’s 4.3-inch Widescreen HMI DOP-B Series is integrated in the industrial sewing machine. The DOP-B Series’full 65,536-color LED screen provides a realistic image display. Users can set up sewing parameters and monitor the production and operation status of the machine easily with the HMI.

The DOP-B Series is equipped with an audio output interface. In case of errors, an alarm alerts users via an audio message in real-time to prevent delays in operation and sewing efficiency.

In addition, Delta’s industrial sewing machine solution adopts the AC Servo Drive ASDA-A2 Series to control two axes of ECMA servo motors for sewing operations. The full-closed loop function reduces the effects of backlash and vibration from the machine and ensures the accuracy of positioning.

The ECMA servo motors feature incremental encoders with 20-bit resolution that can eliminate unstable commands at low speed and enhance accuracy. They also support an absolute 17-bit encoder and are able to maintain motor position when the power is off, fulfilling customer’s expectations for accurate and stable pocket setting. l