Metrology: The Robotic Measuring Cells

For QFP automation represents a further evolution in the metrology sector: QBOX is a range of robotic measuring cells suitable for every type of need and layout. Let’s look in detail two models, that include a cobot and an anthropomorphic robot

by Noemi Sala

Dimensional control is a delicate and fundamental phase of the production process, able both to guarantee consistency and quality to the final product and, in merely productive terms, the reduction of wastes and the costs associated with them.

If we talk about dimensional control, the time variable has an essential impact on the productivity. The metrological control with CMM and probing offers extremely precise results, up to a micron of uncertainty. But the execution of these metrological reports is often very expensive in terms of time, and is not always equally effective on complex geometries. If, on the other hand, we refer to a dimensional check performed manually with templates and gauges, the subjective variable (i.e. skill of the operator) has a heavy impact on the reliability of the final result. For several years, been optical (blue LED light) and laser have been among the technologies that guarantee the best results in terms of accuracy and speed of acquisition of the geometry of the object. QFP, a specialist in the sector and Zeiss business partner for Italy (Zeiss is a manufacturer of precision optics), as well as distributing the products of other brands in the world of measurement.

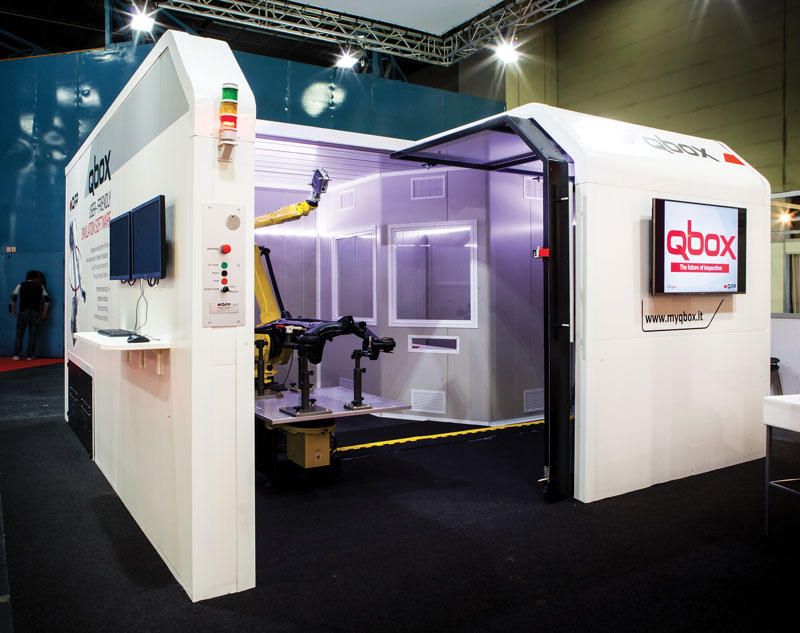

Automation represented a further development frontier in the metrology sector: QFP has created in recent years a range of robotic measuring cells suitable for every type of need and layout, the QBOX range.

The flexible measurement island that integrates a cobot

QBOX Minicobot is the compact and flexible measuring island that integrates a collaborative robot and a Comet Zeiss blue LED light scanning system. It is a measurement system capable of adding the advantages offered by LED scanning (great speed of acquisition even on extremely complex geometries, good performance on non-collaborative surfaces without the need to mark) and those offered by collaborative robotics, therefore safety, ease of use, ergonomics. Minicobot is a system which, due to its compact dimensions and collaboration, can find space in the most saturated of the metrological rooms but, above all, that can cope with short and varied lots thanks to the simplicity of programming and use offered by the cobot. Switching from the measurement set up of one object to another requires a few simple steps. In fact, the same cobot can be guided on the piece and, through free drive programming, the measurement trajectory can be recorded by fixing the points (waypoints) through which the robotic arm has moved, and then making the movement repeat for all the necessary cycles. Minicobot is able to acquire the surfaces of objects up to 300 kg in weight and 1 m (x 1 m) in size.

The high speed measuring cell with an anthropomorphic robot

QFP has also developed a customizable measuring cell: QBOX Power, an installation that includes an anthropomorphic robot and the Zeiss TScan laser scanning system. Laser technology makes it particularly efficient on some of the less collaborative surfaces on the market such as glossy sheet metal, black plastic and carbon fiber. Materials that require preparation and markering if tackled with other tools, can be detected thanks to the TScan in a few minutes. The TScan is composed of two elements: the tracker element that defines the measurement volume within which the second element of the TScan moves (referenced by the tracker itself), the laser gun with which the robot brushes the object to be measured and scanned. The operating volumes of the TScan are three: 10, 20 or 36 cubic meters. It is therefore a solution with which it is possible to cope with metrological processes of even very bulky objects, typical of sectors such as automotive, aerospace, naval. QBOX Power is delimited by perimeter barriers that separate it from the environment in which the operators operate. However, it is designed to be an integral part of production and therefore acts as a quality control station within the production flow. QBOX Power can be adapted according to the space available in the layout: enlarged (Evolution version) or rather reduced (Compact version). The scanning advantages offered by laser technology (speed, ease of use, effectiveness on complex surfaces) are added to those offered by robotic technology which guarantees precision, repeatability, coherence.