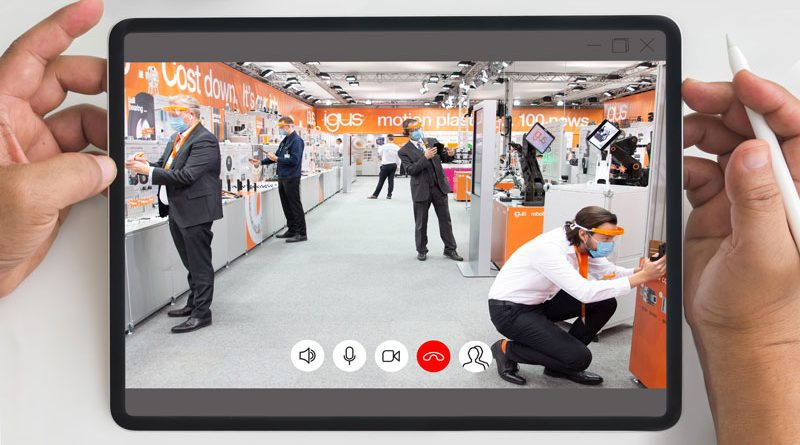

100 new products at the virtual trade show stand

After a 2% increase in turnover last year, igus is currently registering different signals from the market. Whilst sales declined in the first four months due to the Corona situation, incoming orders have remained almost stable so far. The interest in motion plastics, which improve technology and reduce costs, is increasing markedly. So igus has set up a trade show stand where customers can discover digital innovations for themselves.

After a 2% increase in turnover last year, igus is currently registering different signals from the market. Whilst sales declined in the first four months due to the Corona situation, incoming orders have so far remained almost stable. The interest in motion plastics, which improve technology and reduce costs, is increasing markedly. On May 7 igus invited journalists to a virtual press conference for the presentation of over 100 new products.

A 400 square metres virtual stand with plenty of innovations

igus presented over 100 plastics innovations in an area of 400 square metres. One example of how customers can save costs and improve their technology is the autoglide 5 energy chain with steel cable floor guide, which can save 88% installation time in intralogistics and crane systems, with total costs including cables starting at €49 per metre. Another new feature is the drylin polymer telescopic rail, with which, among other things, drawers, seat and head adjustments can be easily made and pulled out. It is also 64% lighter than metal guides. Crucial for product development are the tests in the company’s own 3,800 square metre test laboratory. These enable igus to offer a unique 36-month guarantee on the standard chain range and chainflex cables.

igus is also increasingly focusing on integrating its motion plastics in a circular economy, with initiatives such as “change recycling”, “plastics2oil” and ISO 14001 certification. In the “change recycling” programme, igus takes back discarded plastic energy chains (“e-chains”) regardless of the manufacturer, recycles them and pays a price per kilo in vouchers.